Shaped, composite savoury concentrate comprising gel pieces

A concentrate, gel technology, applied in the field of broth or gravy or soup, preparation of sauce, can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

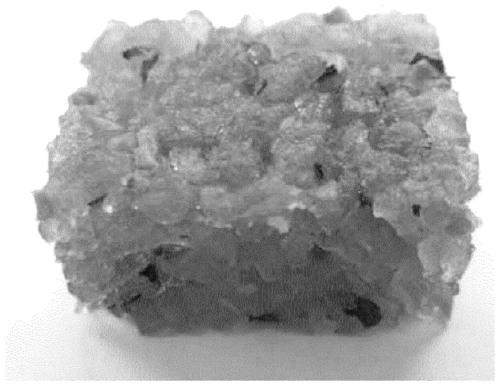

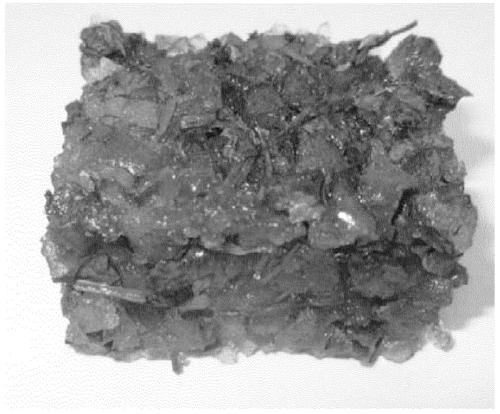

[0085] Shaped complex savory concentrates containing irregular gel pieces were prepared as follows.

[0086] Aqueous gel compositions were prepared based on the formulations shown in Table 1.

[0087] Table 1

[0088] weight% tap water 67.34 Salt 22.54 sugar 2.2 Yeast Extract Powder (<1% Salt)

1.83 turmeric, ground 0.03 Chicken Extract Powder 1.65 monosodium glutamate 2.00 Inosinic acid / guanylic acid 0.20 agar 2.2 white pepper, ground 0.01

[0089] Aqueous gelling compositions were prepared in batches of 15 kg in a pilot plant (Fryma Koruma MaxxD Lab with 4 mm standard toothed rotor-stator). Using a rotor-stator system, the maximum shear force was 2000 rpm and the scraper was constant at 32 rpm. The dry ingredients are sucked through the homogenizer (by applying a vacuum) and mixed into the water in the container to form a homogeneous mixture. The mixture was heated to 100°C and held at this tempe...

Embodiment 2

[0112] The preparation of shaped composite savory concentrates containing gel pieces starts with an aqueous gelling composition having the composition shown in Table 3 below:

[0113] table 3

[0114]

[0115]

[0116] A batch of 1500 g is produced in a Thermomix TM31 device. Mix the powder ingredients evenly into the water at 40°C while stirring at maximum speed 5. Next, the mixture was heated to 85°C and kept at 85°C for 3 minutes, then filled into a rectangular container (about 1.3 kg), then covered with a plastic film and kept at 5°C overnight.

[0117] The cooled gel was cut into pieces of approximately 5 x 5 x 5 cm. Approximately 1.3 kg of these cubes were transferred to a Lab ADE table cutter (approximately 111 size; equipped with 3 sickles) and cut in approximately 12 seconds at speed 1 (20 rpm). Remove the gel piece from the cutter. The gel mass was sieved through a 5mm sieve and a 0.5mm sieve to obtain a fraction with a particle size of 0.5-5mm. The cut ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com