High-purity metal vanadium powder and preparation method thereof

A metal, high-purity technology, applied in the field of high-purity metal vanadium powder and its preparation, can solve the problems of unsatisfactory purity of metal vanadium powder, related impurity element types and quantity constraints, etc., achieve high production efficiency and improve comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of high-purity metal vanadium powder, this metal vanadium powder comprises following components and content (weight):

[0024] (1) Composition: Fe content: 0.017%, Si content: 0.01%, Cr content: 0.026%, Al content: ≤0.01%, O content: ≤0.026%, V content: balance (weight percentage);

[0025] (2) Particle size: -100 mesh (standard mesh number).

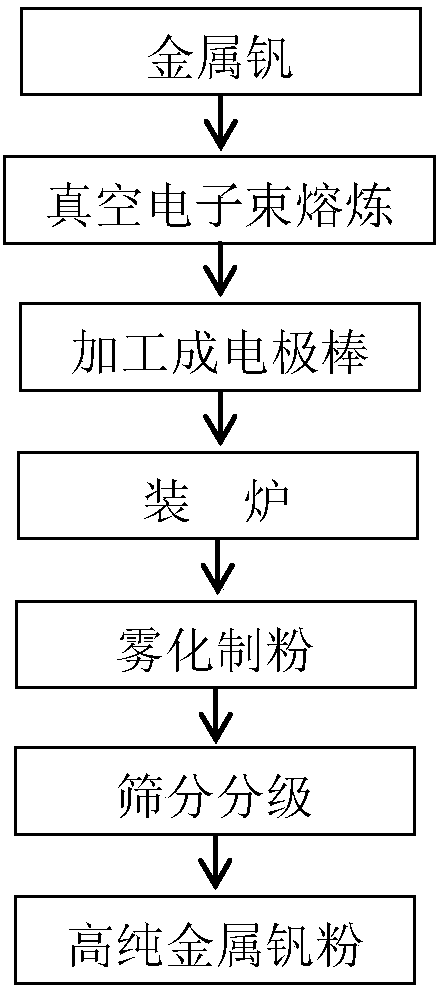

[0026] The preparation process of the high-purity metal vanadium powder comprises the following steps:

[0027] (1) Electrode rod preparation: the metal vanadium prepared by the molten salt electrolysis method is prepared by vacuum electron beam melting into a metal vanadium round rod with a diameter of φ50mm, and is machined into an electrode rod with a diameter of φ40mm×300mm;

[0028] (2) Electrode rod loading: the electrode rod is loaded into the atomization chamber of the atomization device through the mechanical shaft, the electrode rod extends into the atomization chamber, and the length of the electrode rod rising...

Embodiment 2

[0033] A kind of high-purity metal vanadium powder, this metal vanadium powder comprises following components and content (weight):

[0034] (1) Composition: Fe content: 0.016%, Si content: ≤0.01%, Cr content: 0.018%, Al content: ≤0.01%, O content: ≤0.023%, V content: balance, (weight percentage);

[0035] (2) Particle size: -60 mesh (standard mesh number).

[0036] The preparation process of the high-purity metal vanadium powder comprises the following steps:

[0037] (1) Electrode rod preparation: the metal vanadium prepared by the molten salt electrolysis method is prepared by vacuum electron beam melting into a metal vanadium round rod with a diameter of φ75mm, and is machined into an electrode rod with a diameter of φ70mm×1000mm;

[0038] (2) Electrode rod loading: the electrode rod is loaded into the atomization chamber of the atomization device through the mechanical shaft, the electrode rod extends into the atomization chamber, and the length of the electrode rod risi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap