Denitrification method of organic waste liquid

An organic waste liquid, nitrogen technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of many treatment steps and slow removal speed, and achieve simple treatment steps, rapid nitrogen removal, and reduced The effect of total nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A nitrogen removal method for organic waste liquid, comprising:

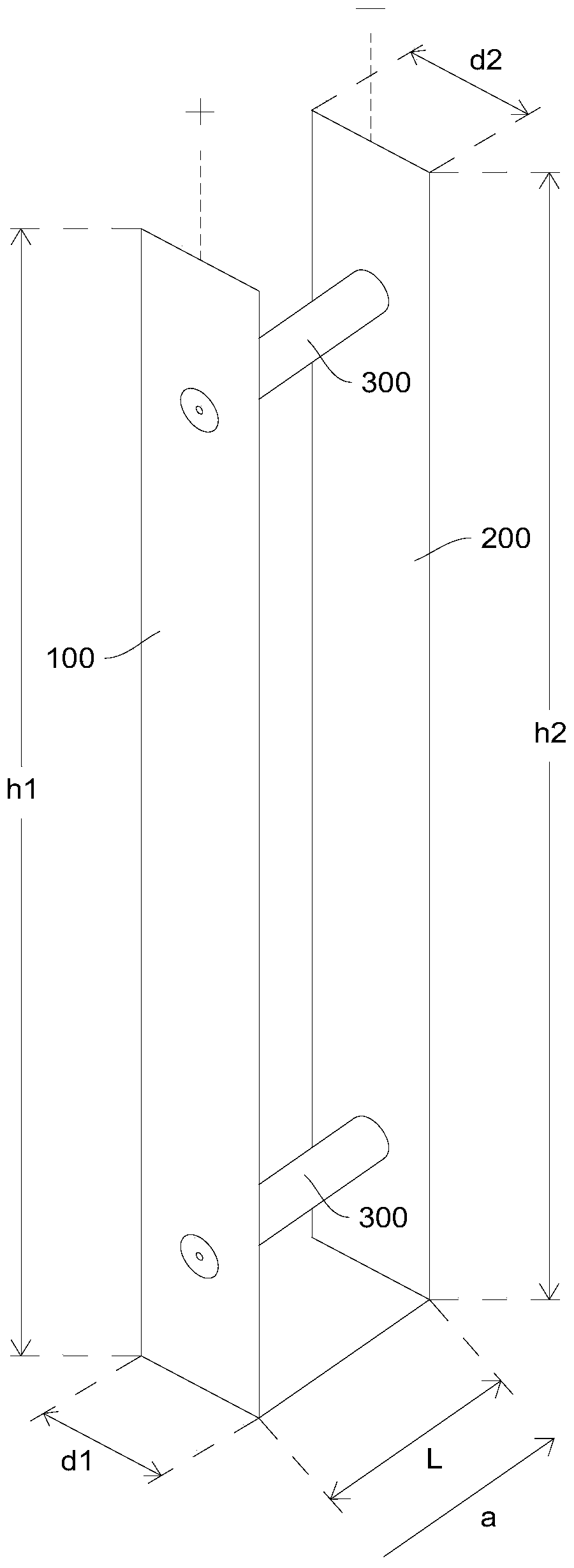

[0034]S1. A titanium plate is used as the anode 100 and a graphite plate is used as the cathode 200, and the anode 100 and the cathode 200 are fixed on both ends of the insulator 300 to form a reaction cell; a reaction cell is arranged in every 100mL of organic waste liquid.

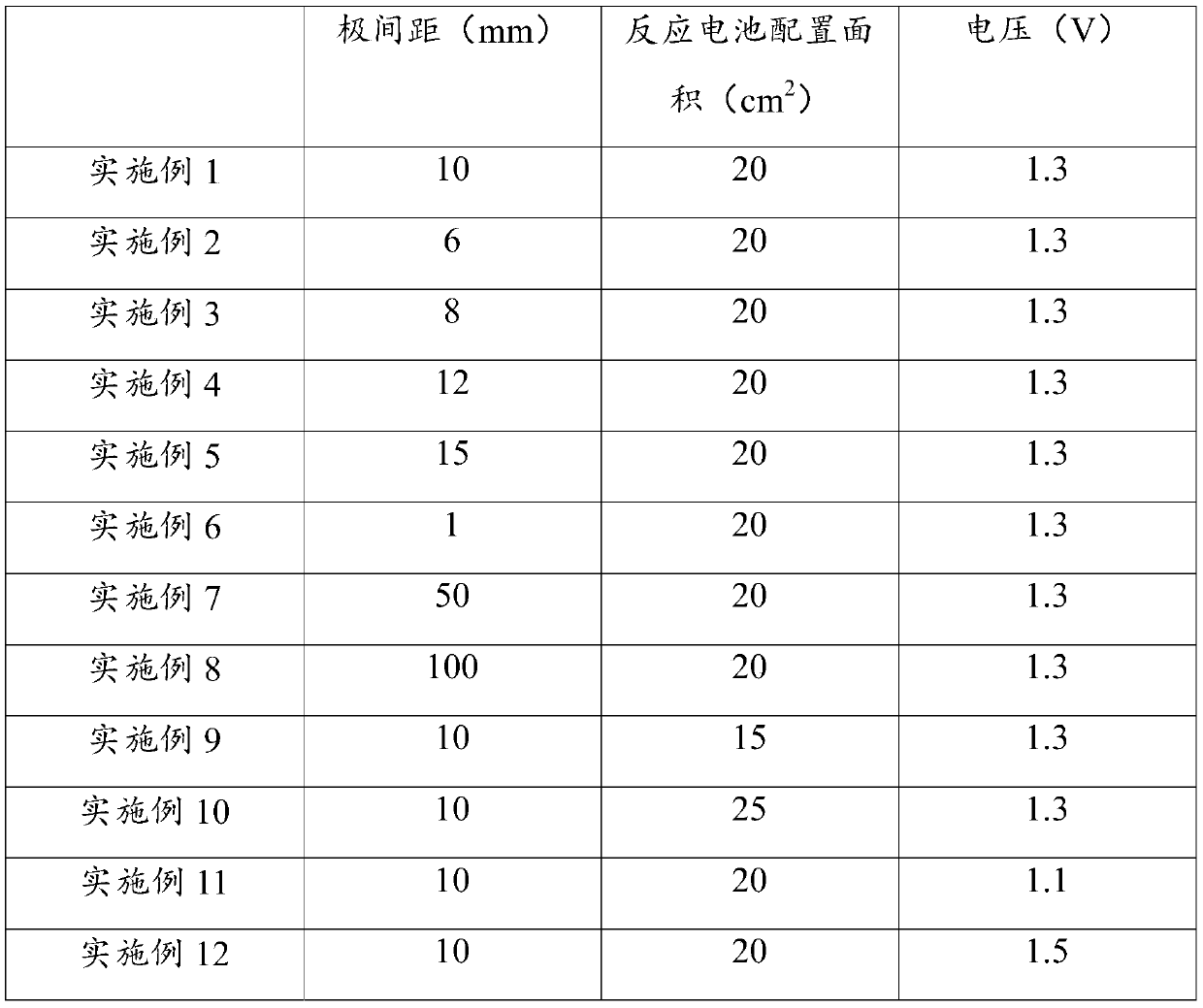

[0035] Among them, the organic waste liquid is landfill leachate, and the initial nitrogen content of the organic waste liquid is 217ppm; the specifications of the anode 100 and the cathode 200 are the same, the distance between the anode 100 and the cathode 200 and the reaction cell configured in every 100mL of organic waste liquid The area is shown in Table 1.

[0036] S2. Using a DC power supply to apply a voltage to each reaction cell, so that the reaction cell performs electrolytic treatment on the organic waste liquid until the residual nitrogen content in the organic waste liquid is less than 5 ppm.

[0037] Wherein, the vol...

Embodiment 2-8

[0039] A nitrogen removal method for organic waste liquid, which differs from Example 1 only in that:

[0040] The distance between the anode 100 and the cathode 200 is different from that in Embodiment 1, please refer to Table 1 for details.

Embodiment 9-10

[0042] A nitrogen removal method for organic waste liquid, which differs from Example 1 only in that:

[0043] The area of the reaction cell configured in every 100mL of organic waste liquid is different from that in Example 1, please refer to Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com