Plugging agent, preparation method and application thereof

A technology of plugging agent and coagulation accelerator, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of shortening curing time, reducing economic losses, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

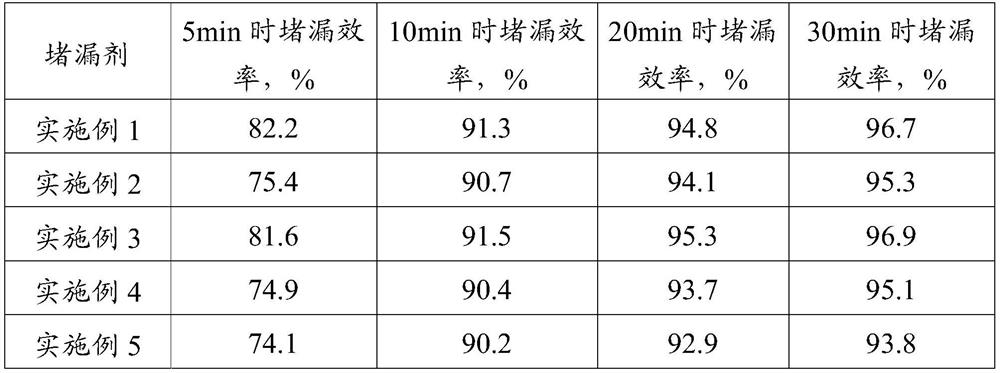

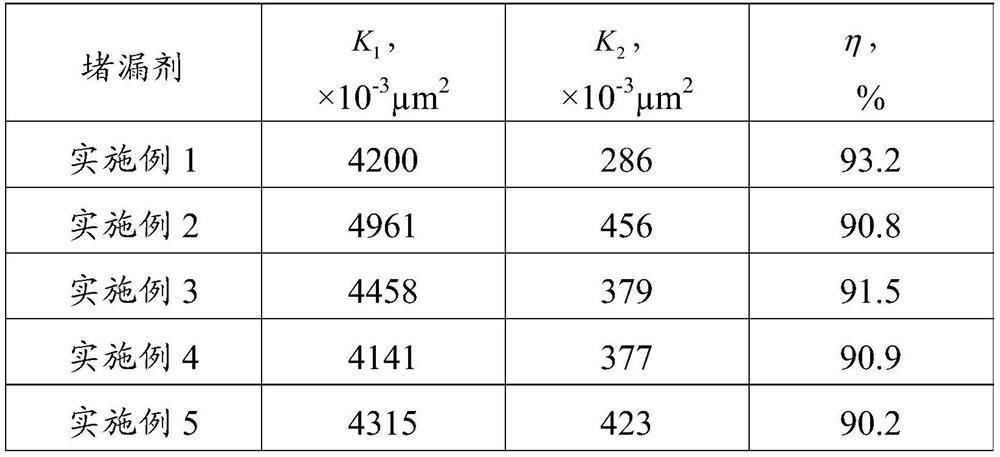

Examples

preparation example Construction

[0037] In a second aspect, the embodiments of the present invention provide a method for preparing the above-mentioned leakage stoppage agent, the preparation method comprising:

[0038] Step 1: According to the weight percentage of each component, tap water is added into the mixing tank.

[0039] The weight percentage of each component is 2%-4% of consolidatable quartz sand, 1%-3% of coagulant, 3%-5% of latex polymer, 3%-5% of sheet material, and 0.2% of fiber material ~0.3%, oil well cement 23%~29%, and tap water as the balance. According to the weight percentages of the above-mentioned components, a certain weight percentage of tap water is added into the mixing tank.

[0040] Step 2: Add the latex polymer to the mixing tank and mix well.

[0041] The specific process of this step is as follows: add the latex polymer with a weight percentage of 23% to 29% into the stirring tank added with tap water, and stir evenly.

[0042]Wherein, the stirring time can be set and chang...

Embodiment 1

[0050] This embodiment provides a leak-stopping agent, which is prepared by the following method:

[0051] Add 600 grams of tap water to the mixing tank; add 30 grams of latex polymer to the mixing tank and stir evenly; add 3 grams of fiber material to the mixing tank and stir evenly; add 290 grams of oil well cement and 22 grams of Consolidate quartz sand, 30 grams of flake material and 25 grams of coagulant, stir and mix evenly to obtain the plugging agent provided in this embodiment.

Embodiment 2

[0053] This embodiment provides a leak-stopping agent, which is prepared by the following method:

[0054] Add 610 grams of tap water to the mixing tank; add 34 grams of latex polymer to the mixing tank and stir evenly; add 3 grams of fiber material to the mixing tank and stir evenly; add 273 grams of oil well cement and 20 grams of Consolidate quartz sand, 30 grams of flake material and 30 grams of coagulant, stir and mix evenly to obtain the plugging agent provided in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com