High-durability low-viscosity high-strength machine-made sand concrete as well as preparation method and application thereof

A machine-made sand and low-viscosity technology, which is applied in the field of building materials to achieve the effect of reasonable particle size matching, improved durability, and improved construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

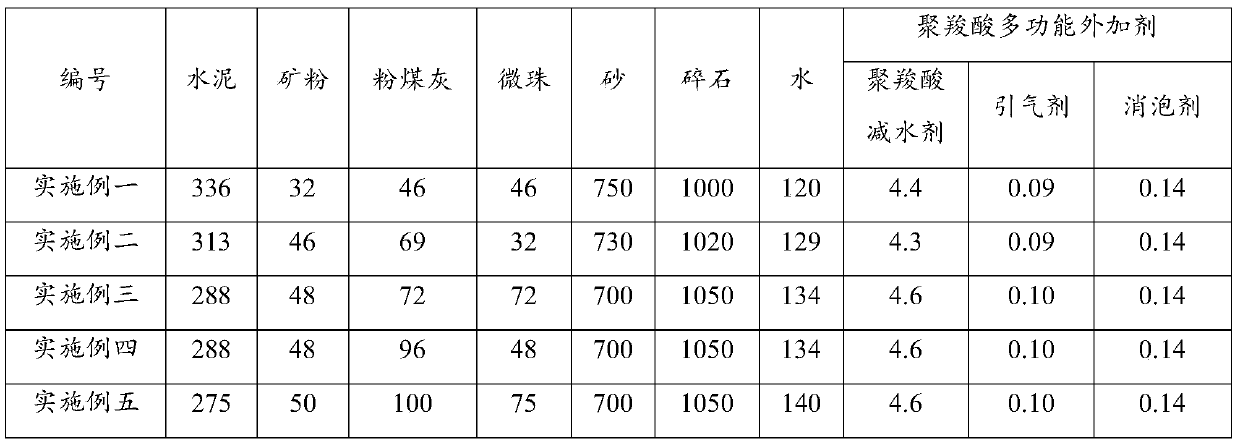

Examples

Embodiment Construction

[0022] The idea, specific structure and technical effects of the present application will be further described below, so as to fully understand the purpose, features and effects of the present application.

[0023] The sources of raw materials used in this example are shown in Table 1.

[0024] The source of each raw material of table 1 present embodiment

[0025] raw material Manufacturer cement Jiangsu Baling Conch Cement Co., Ltd. fly ash Huaian Huaneng Renewable Resources Utilization Co., Ltd. mineral powder Rizhao Jinghua New Material Co., Ltd. microbeads Shenzhen Daote Technology Co., Ltd. sand Lianyungang Dadaoshan Fuqiang Quarry gravel Shandong Linshu Dongyuezhuang Quarry Polycarboxylate multifunctional admixture Shanghai High-speed Railway Chemical Building Materials Co., Ltd.

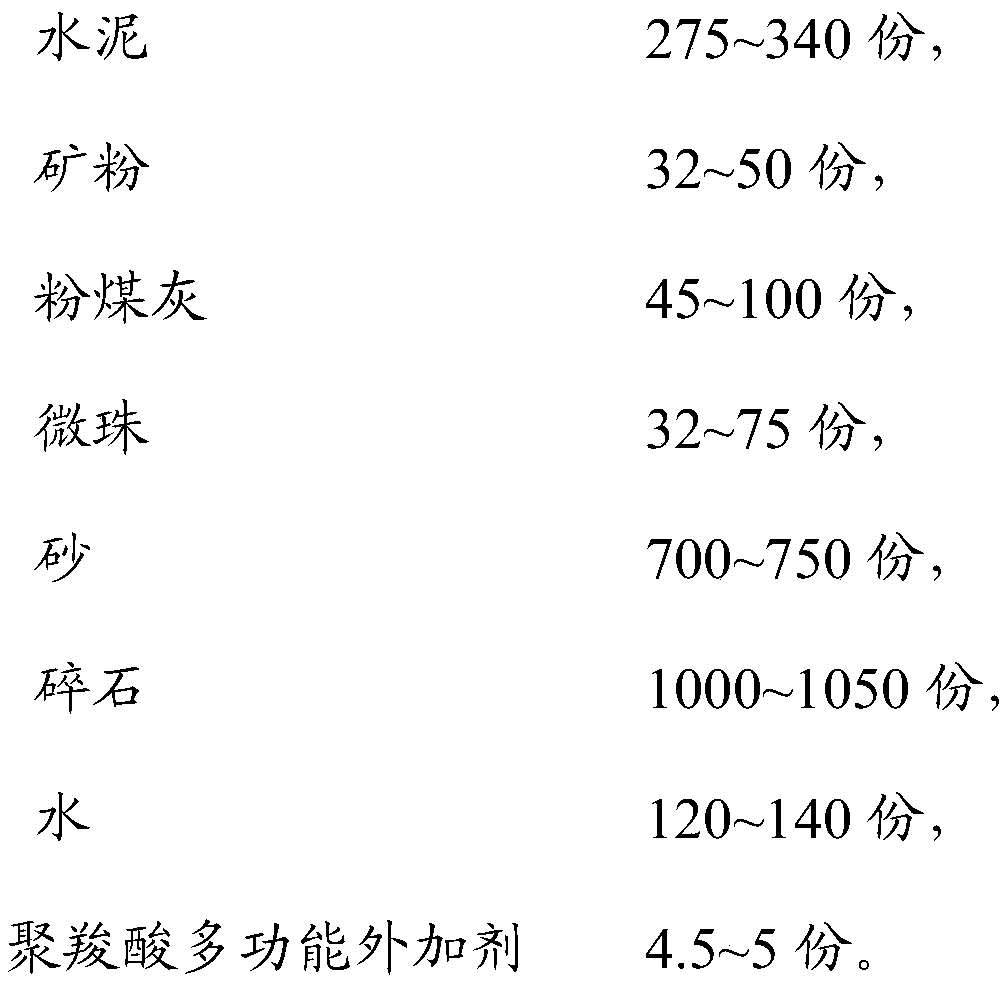

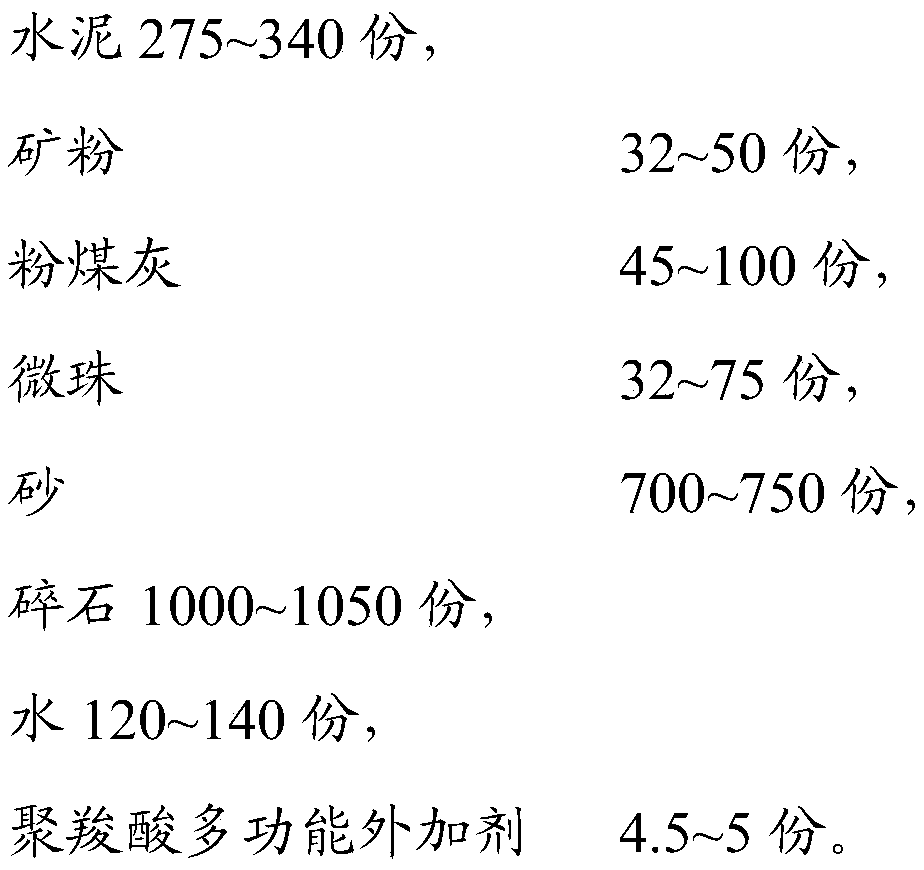

[0026] In each embodiment of the application, the composition of the raw materials according to the weight fraction is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com