Method for preparing metal two-dimension nanometer anti-friction thin film through shearing, hot-pressing and combination

A technology of two-dimensional nano and metal nanoparticles, which is applied in the field of preparing two-dimensional nano metal anti-friction films, can solve the problems of single deformation form, high surface roughness, narrow synthesis temperature range, etc., to reduce complexity and reduce agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

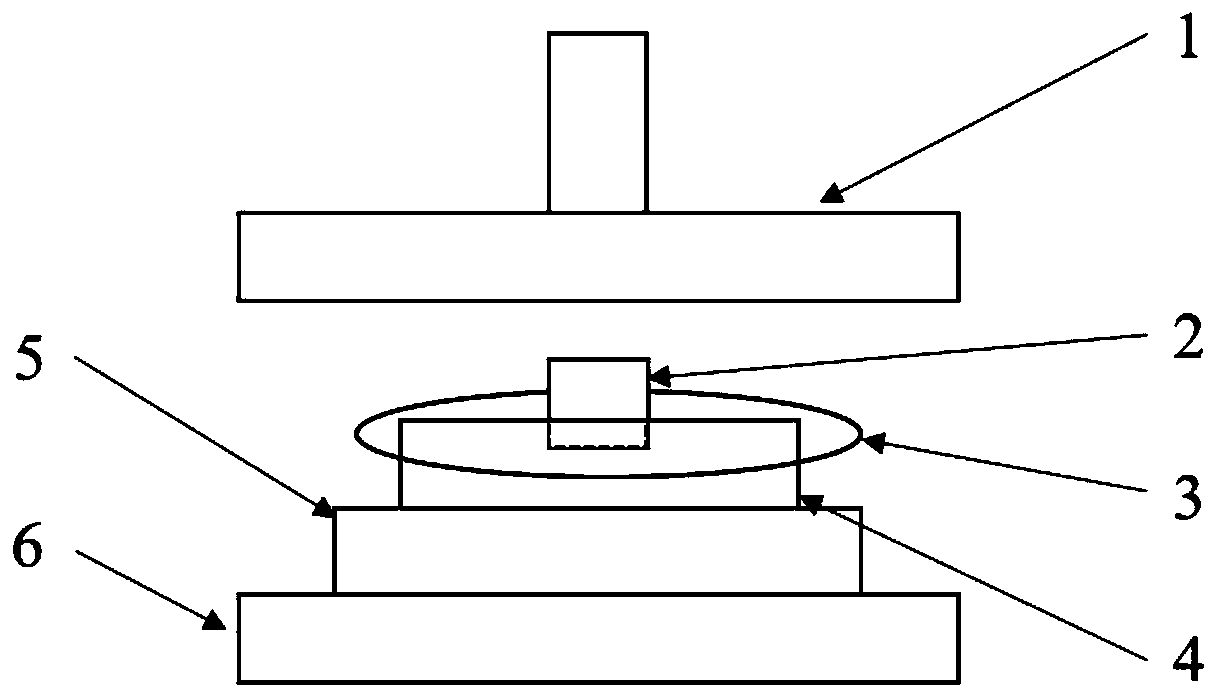

[0029] A method for preparing a metal two-dimensional nano-friction-reducing film by shearing and hot pressing, the preparation steps are:

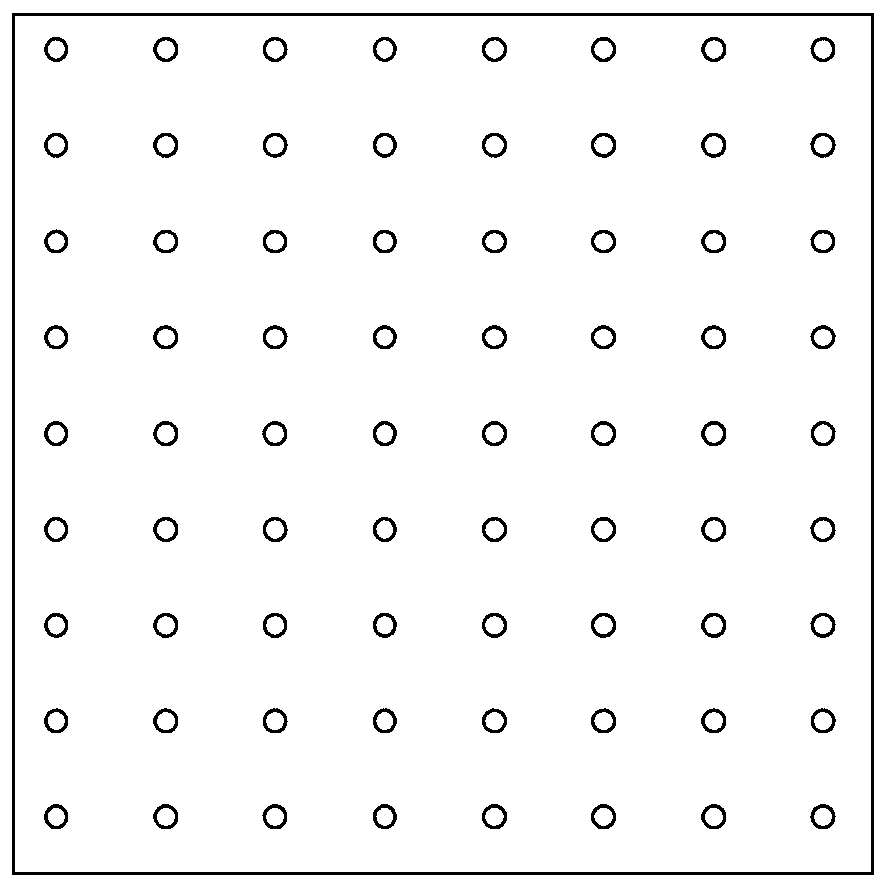

[0030] Step 1. On a clean silicon substrate, evenly spread metal nanoparticles with a concentration of 1-2 mg / L. The method for dispersing the solution is as follows: accurately weigh the metal powder into a centrifuge tube, and add a corresponding amount of ethanol solution. Prepare an ethanol solution with a concentration of 1-2 mg / L. The solution was first treated with magnetic stirring for 30 minutes, then ultrasonicated for 30 minutes, then centrifuged for 10 minutes, repeated magnetic stirring for 10 minutes, and finally ultrasonicated for 10 minutes. Make the metal powder highly dispersed in the ethanol solution, use a pipette to draw 38~40 μL and drop it on 1x1 cm 2 on a silicon substrate. Finally, using a light microscope to observe the spreading of metal nanoparticles on the silicon substrate, the results are as follows: fig...

Embodiment 2

[0037] A two-dimensional nano-metal friction reducer, including metal two-dimensional thin film material, the metal two-dimensional material is composed of the following weight of raw materials: 4 mg of metal powder with a relatively uniform particle size and 50 mL of absolute ethanol; The metal powder consisted of the following metal powders: Au powder 4 mg.

[0038] Its preparation method comprises the following steps:

[0039] Step 1, put the substrate 2 into ethanol for the first step of cleaning, then use a cotton swab to scrub, and finally dry it for later use.

[0040]Step 2: First, fill a 50 mL centrifuge tube with ethanol and ultrasonically clean it for later use, use a precision balance to weigh the metal powder into the centrifuge tube, and pour absolute ethanol into the centrifuge tube. The prepared solution was first ultrasonicated in an ultrasonic instrument for 30 min, then the solution was centrifuged for 10 min, magnetic stirring was repeated for 10 minutes, ...

Embodiment 3

[0046] A two-dimensional nano-metal friction reducer, including metal two-dimensional thin film material, the metal two-dimensional material is composed of the following weight of raw materials: 6 mg of metal powder with a relatively uniform particle size and 50 mL of absolute ethanol; The metal powder consisted of the following metal powders: Cu powder 4 mg.

[0047] Its preparation method comprises the following steps:

[0048] Step 1, put the substrate 2 into ethanol for the first step of cleaning, then use a cotton swab to scrub, and finally dry it for later use.

[0049] Step 2: First, fill a 50 mL centrifuge tube with ethanol and ultrasonically clean it for later use, use a precision balance to weigh the metal powder into the centrifuge tube, and pour absolute ethanol into the centrifuge tube. The prepared solution was first ultrasonicated in an ultrasonic instrument for 30 min, then the solution was centrifuged for 10 min, magnetic stirring was repeated for 10 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com