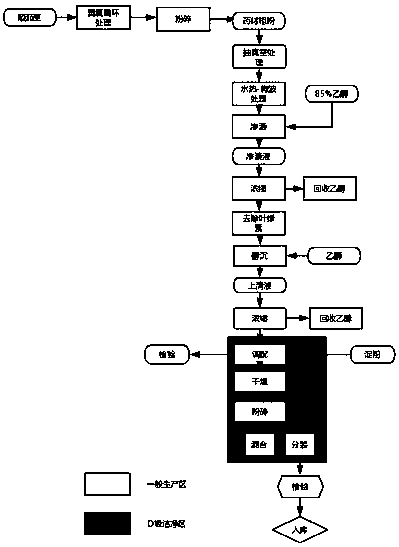

Production process for belladonna herb extract

A production process and technology for belladonna extract, applied in the field of production technology of belladonna extract, can solve the problems of affecting the color and shape of the extract, low content of active ingredients, reducing the medicinal efficacy of the extract, etc., so as to improve the purity of the extract , the effect of reducing chlorophyll content and increasing alkaloid precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of production technique of belladonna extractum, concrete production technique is as follows:

[0019] 1) Remove impurities, insects, mildew and non-medicinal parts of belladonna, then put 1000kg of belladonna into the processor, add distilled water to submerge the belladonna, and then pressurize the processor to 0.2MPa, and simultaneously feed ozone and distilled water into the processor for 2.5 hours of circulating treatment, wherein the flow rate of distilled water is 12L / min, and the flow rate of ozone is 1L / min. ;

[0020] 2) Put the drained belladonna powder into a coarse powder, then put the belladonna coarse powder into a vacuum treatment tank, inject 3 times the amount of distilled water into the belladonna coarse powder, and first vacuumize to -0.02 MPa, negative pressure treatment 20min, remove vacuum then, pressurize to 0.2MPa, pressurize treatment 40min, repeat processing 2 times, obtain the belladonna coarse powder of saturated state, then use the ...

Embodiment 2

[0027] A kind of production technique of belladonna extractum, concrete production technique is as follows:

[0028] 1) Remove impurities, insects, mildew and non-medicinal parts of belladonna, then put 1000kg of belladonna into the processor, add distilled water to submerge the belladonna, and then pressurize the processor to 0.25MPa, and simultaneously feed ozone and distilled water into the processor for 2 hours of circulation treatment, wherein the flow rate of distilled water is 14L / min, and the flow rate of ozone contained is 1.5L / min. After the treatment is completed, take out the belladonna and drain the water reserve;

[0029] 2) Put the drained belladonna powder into a coarse powder, then put the belladonna coarse powder into a vacuum treatment tank, inject 4 times the amount of distilled water into the belladonna coarse powder, and first vacuumize to -0.05 MPa, negative pressure treatment 15min, remove vacuum then, pressurize to 0.3MPa, pressurize treatment 35min, ...

Embodiment 3

[0036] A kind of production technique of belladonna extractum, concrete production technique is as follows:

[0037] 1) Remove impurities, insects, mildew and non-medicinal parts of belladonna, then put 1000kg of belladonna into the processor, add distilled water to submerge the belladonna, and then pressurize the processor to 0.3MPa, and simultaneously feed ozone and distilled water into the processor for 1.5h circulation, wherein the flow rate of distilled water is 15L / min, and the flow rate of ozone is 2L / min. ;

[0038] 2) Put the drained belladonna powder into a coarse powder, then put the belladonna powder into a vacuum treatment tank, inject 5 times the amount of distilled water into the belladonna powder, and first vacuumize to -0.08 MPa, negative pressure treatment 10min, remove vacuum then, pressurize to 0.5MPa, pressurize treatment 30min, repeat processing 3 times, obtain the belladonna coarse powder of saturated water state, then use the belladonna coarse powder o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com