An industrial workshop dust removal and desulfurization equipment and its use method

The technology of desulfurization equipment and workshop is applied in the field of dust removal and desulfurization equipment in industrial workshops. contact full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

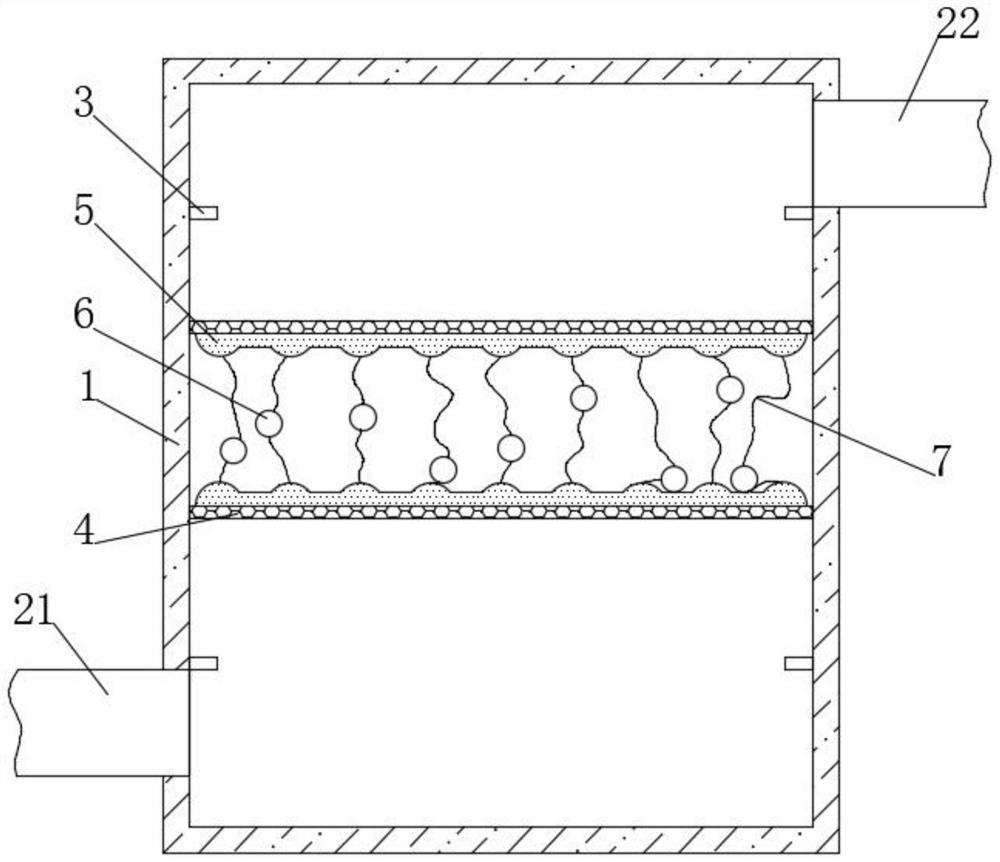

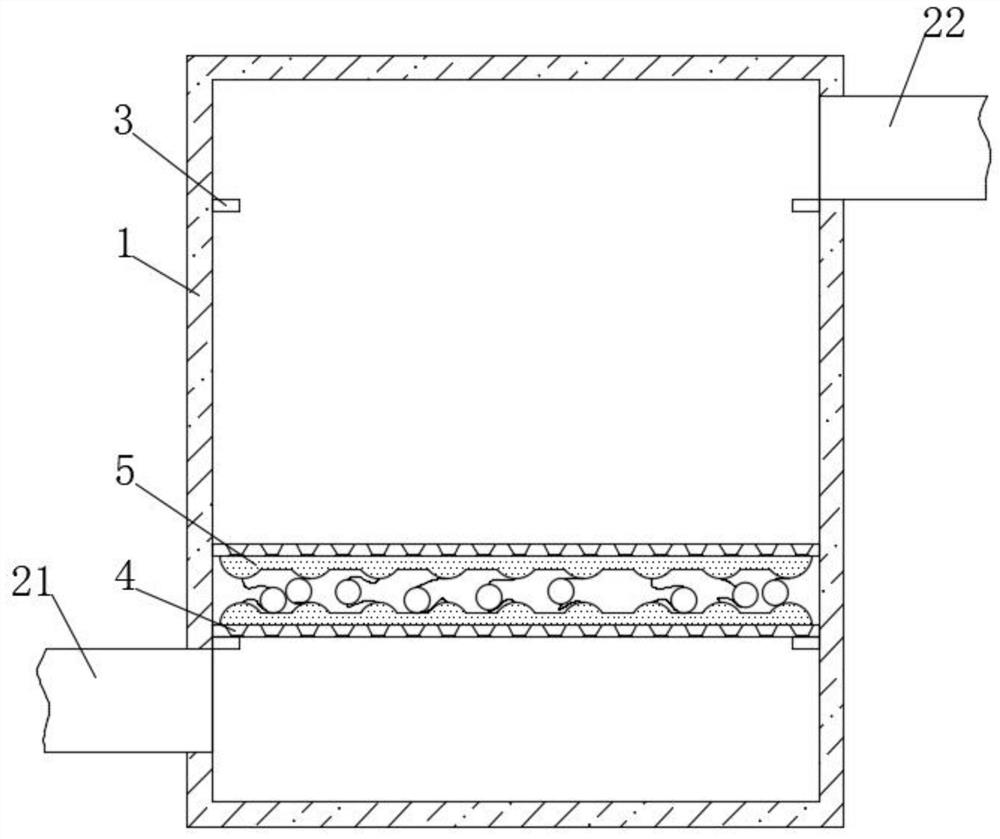

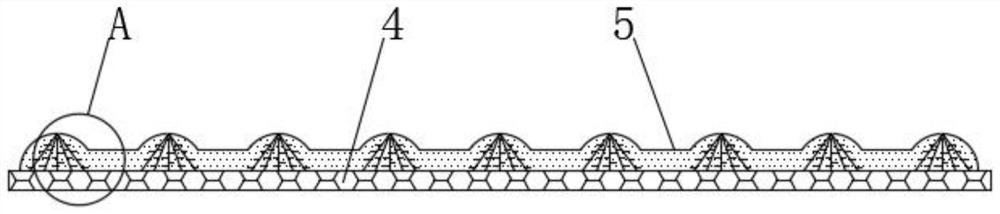

[0047] see figure 1 , an industrial workshop dust removal and desulfurization equipment, including a device body 1 with a sealed transparent door, an air inlet pipe 21 is fixedly connected to the lower left end of the device body 1, an air outlet pipe 22 is fixedly connected to the upper right end of the device body 1, the air inlet pipe 21 and the air outlet pipe 22 are all communicated with the device body 1, the device body 1 is fixedly connected with two baffles 3 inside, and the device body 1 is slidingly connected with two mutually symmetrical wind bomb automatic filter plates, and the two baffles 3 are respectively located On both sides of the plate, and two baffles 3 are located between the air intake pipe 21 and the air outlet pipe 22, a plurality of wind-driven pinballs 6 are arranged between the two wind-bomb automatic filter plates, and the internal activities of the wind-driven pinballs run through the limit rope 7 , the two ends of the limit rope 7 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com