Preparation method of biomimetic impact-resistant multilayer composite gradient material based on amorphous alloy

An amorphous alloy and multi-layer composite technology, which is applied in the field of bionics and 3D printing materials, can solve problems such as temperature exceeding and material crystallization, and achieve excellent wear resistance and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

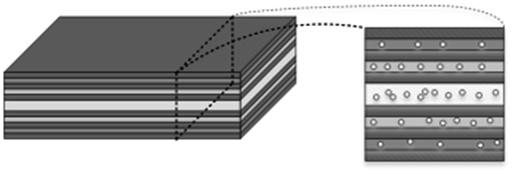

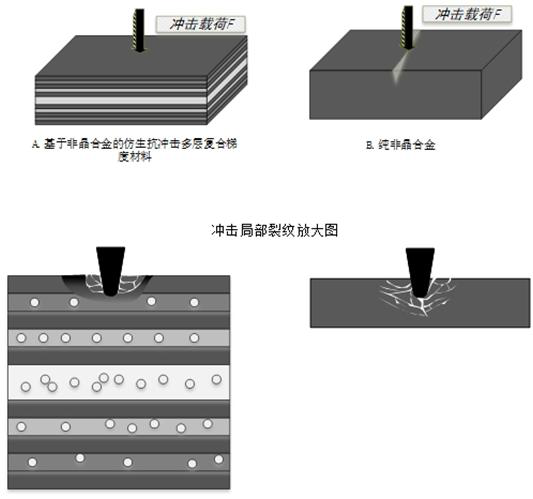

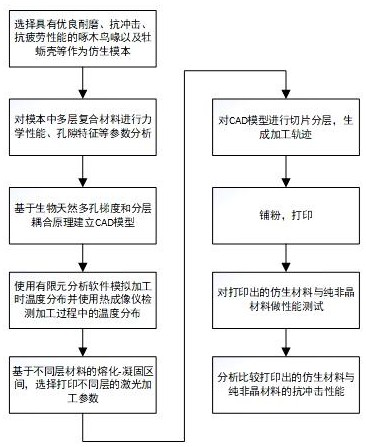

[0034] see Figure 1 to Figure 3As shown, the preparation method of the bionic impact-resistant multi-layer composite gradient material based on amorphous alloy of the present invention is to establish a CAD model by selecting woodpecker beaks, oyster shells and other biological materials with porous gradient characteristics and multi-layer composite characteristics as bionic models, The bionic impact-resistant multi-layer composite gradient material is prepared by using amorphous alloy powder as the raw material and the selective laser melting forming technology, and the materials of different layers are printed by 3D printing, so as to obtain the bionic material with high impact load resistance. Multilayer composite gradient material. Through the comparative analysis of the biomimetic impact-resistant multilayer composite gradient material, alloy material and pure amorphous alloy material, we can find that the biomimetic impact-resistant multilayer composite gradient materia...

Embodiment

[0048] This embodiment provides a metal composite material for 3D printing. The raw material is uniform and fine zirconium-copper-aluminum-nickel alloy powder. By setting different laser parameters, an amorphous alloy layer and a crystalline alloy layer with different porosity are printed.

[0049] 1) Select biomaterial structures such as woodpecker beaks and oyster shells with excellent wear resistance, crack arrest, and fatigue resistance as bionic models. The layered differences in peeling behavior and mechanical properties were tested to obtain the mechanical parameters and pore characteristics of the material structure. Establish the CAD model of the multi-layer composite gradient material part, the cuboid model, length × width × height: 60mm × 30mm × 10mm.

[0050] 2) Use laser as the processing heat source, select Zr-based zirconium-copper-aluminum-nickel alloy powder material, determine laser processing parameters power P=300~500W, beam diameter D=1mm, beam moving spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com