Automobile hydrogenated butadiene-acrylonitrile rubber PCV valve diaphragm forming die and machining method

A technology of hydrogenated nitrile rubber and forming molds, which is used in household appliances, other household appliances, applications, etc., can solve the problems of inability to prevent rubber spillage, inability to use brushing and spraying processes, and poor product appearance, so as to avoid appearance. The effect of improving production efficiency and product qualification rate, and saving vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

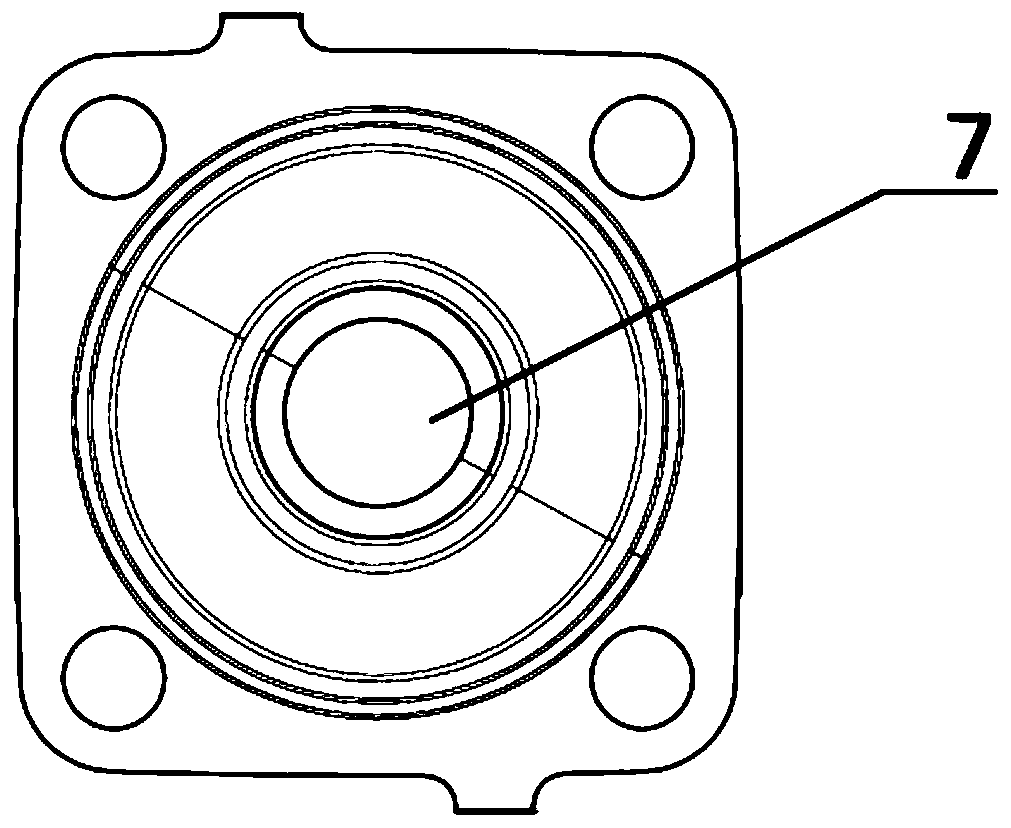

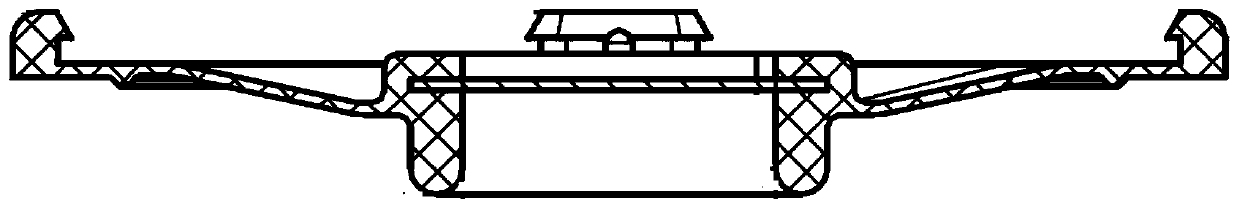

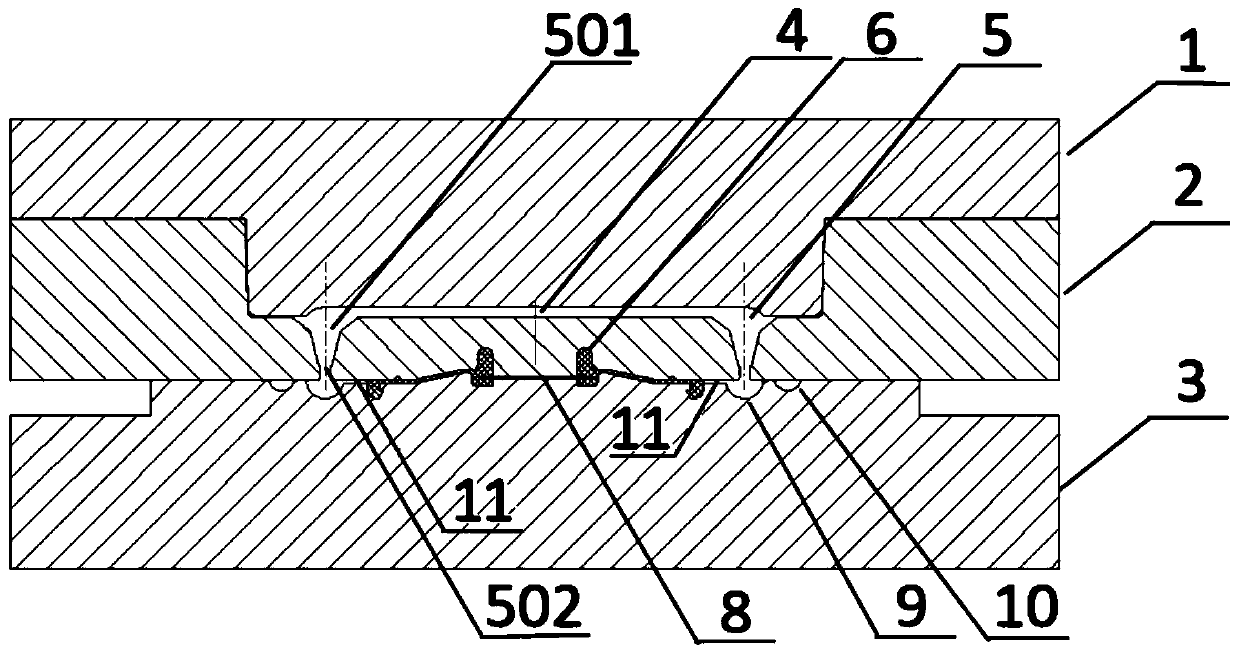

[0043] Combine figure 1 , The hydrogenated nitrile rubber PCV valve diaphragm molding mold for automobiles of this embodiment includes an upper mold 1, a middle mold 2 and a lower mold 3. The upper mold 1 and the middle mold 2 are closed to form an injection cavity 4, the middle mold 2 After being combined with the lower mold 3, a rubber cavity 6 and a metal skeleton cavity 8 are formed. The middle mold 2 is provided with a round cone shaped plastic injection hole 5 with a large upper and a small lower mold. The glue dot 9 is in communication with the rubber cavity 6 through a diversion port 11.

[0044] In the prior art, rubber is usually injected directly into the product cavity and extrusion molding is performed by using a mold. However, because the PCV valve diaphragm of the present invention has irregular shapes and relatively thin dimensions, if the rubber is directly injected into the product cavity, When the vulcanization molding is finished, the product is easily torn wh...

Embodiment 2

[0048] In this embodiment, a hydrogenated nitrile rubber PCV valve diaphragm molding die for automobiles has basically the same structure as Embodiment 1. Furthermore, in this embodiment, the upper mold 1 and the middle mold 2 are closed to form an injection cavity 4 The thickness is 0.3-0.5mm. Because the PCV valve diaphragm of this embodiment is relatively thin and does not require too much rubber material for injection molding, the size of the injection cavity 4 is too large, but it will affect the product yield, specifically in this embodiment The thickness of the middle injection pressure cavity 4 is 0.4 mm.

[0049] Further, in this embodiment, the mold 2 and the lower mold 3 are respectively provided with an upper edge sealing boss 201 and a lower edge sealing boss 301 along the non-encapsulated surface of the metal skeleton 7. Specifically, the upper edge sealing boss 201 in this embodiment The height between the lower edge sealing boss 301 and the lower edge sealing boss...

Embodiment 3

[0054] The method for processing a hydrogenated nitrile rubber PCV valve diaphragm for automobiles in this embodiment, using the above-mentioned mold for processing, specifically includes the following steps:

[0055] Step 1. Preparation of metal frame 7 and PCV valve diaphragm body rubber

[0056] Gasoline cleaning and drying of the metal frame 7, use the dipping method to dip the surface of the frame with adhesive CHEMLOKTS701-43, and dry it at 20℃~30℃ for 0.5~1 hour, and cut the PCV valve diaphragm according to the size of the forming mold Body rubber; specifically in this embodiment, the metal frame 7 is made of 304 stainless steel, with a maximum outer diameter of 18mm and a thickness of 0.4mm. The PCV valve diaphragm body rubber is 7-9mm in thickness and 40-45 grams in weight Square.

[0057] Step 2: Fill in the metal frame 7 and the body rubber of the PCV valve diaphragm

[0058] Assemble the forming mold on the plate vulcanizer, then place the metal skeleton 7 in the metal sk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com