Polyolefin self-adhesive heavy packaging film and preparation method thereof

A technology of polyolefin and packaging film, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of low lapping and peeling force of the film, easy occurrence of loose packages, low lapping and peeling force of self-adhesive packets, and poor use stability. , to achieve the effect of high lap peel strength, excellent tensile strength and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

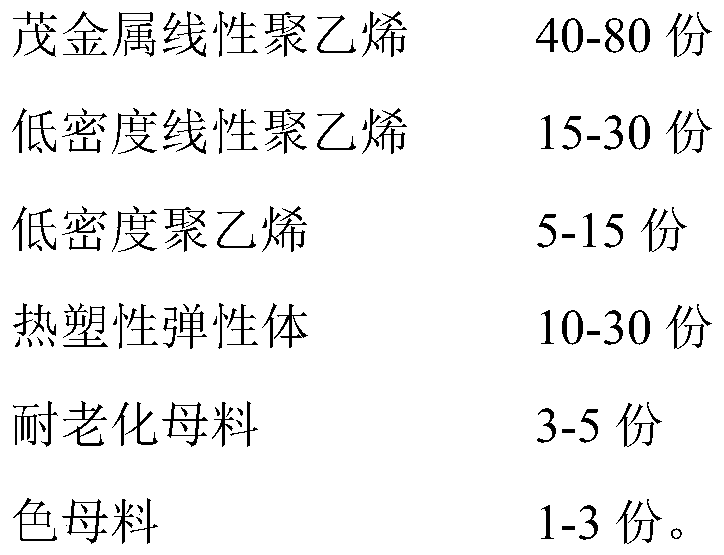

[0054] The polyolefin self-adhesive heavy packaging film described in Example 1 is composed of an inner layer, a middle layer and an outer layer, and the ratio of raw materials of each layer is as shown in Table 1 below:

[0055] Table 1 Example 1 polyolefin self-adhesive heavy packaging film raw material ratio table

[0056]

[0057] The preparation method of the polyolefin self-adhesive heavy packaging film described in the present embodiment 1 consists of the following steps:

[0058] Weigh the above raw materials according to the formula, put them into the mixer in layers and mix them for 30 minutes, and then send them into the inner, middle and outer layer hoppers of the corresponding three-layer co-extrusion blow molding equipment through the automatic feeder. The temperature setting of each section: 170°C, 200°C, 220°C, 220°C; the connecting body temperature is set at 215°C, the die head temperature is set at 210°C; the length-to-diameter ratio of the extruder screw ...

Embodiment 2

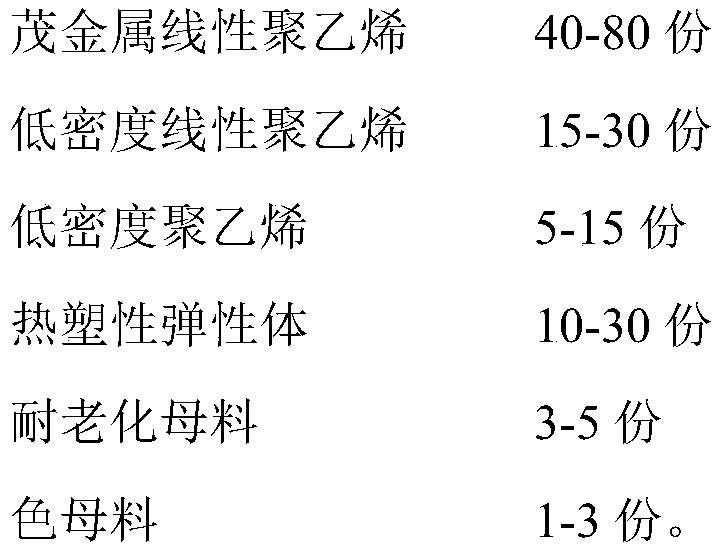

[0061] The polyolefin self-adhesive heavy packaging film described in Example 2 is composed of an inner layer, a middle layer and an outer layer, and the raw material ratio of each layer is as shown in Table 2 below:

[0062] Table 2 Example 2 polyolefin self-adhesive heavy packaging film raw material ratio table

[0063]

[0064] The preparation method of the polyolefin self-adhesive heavy packaging film described in the present embodiment 2 consists of the following steps:

[0065] Weigh the above raw materials according to the formula, put them into the mixer in layers and mix them for 30 minutes, and then send them into the inner, middle and outer layer hoppers of the corresponding three-layer co-extrusion blow molding equipment through the automatic feeder. The temperature setting of each section: 170°C, 200°C, 220°C, 220°C; the connecting body temperature is set at 215°C, the die head temperature is set at 210°C; the length-to-diameter ratio of the extruder screw is 3...

Embodiment 3

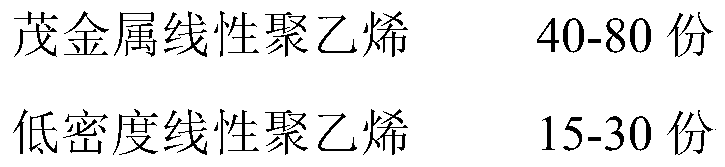

[0068] The polyolefin self-adhesive heavy-duty packaging film described in Example 3 is composed of an inner layer, a middle layer and an outer layer, and the raw material ratio of each layer is as shown in Table 3 below:

[0069] Table 3 Example 3 polyolefin self-adhesive heavy packaging film raw material ratio table

[0070]

[0071] The preparation method of the polyolefin self-adhesive heavy packaging film described in this embodiment 3 consists of the following steps:

[0072] Weigh the above raw materials according to the formula, put them into the mixer in layers and mix them for 30 minutes, and then send them into the inner, middle and outer layer hoppers of the corresponding three-layer co-extrusion blow molding equipment through the automatic feeder. The temperature setting of each section: 170°C, 200°C, 220°C, 220°C; the connecting body temperature is set at 215°C, the die head temperature is set at 210°C; the length-to-diameter ratio of the extruder screw is 30:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com