Overturning and positioning device for multiple silicon wafers

A technology for positioning devices and silicon wafers, which is applied in transportation and packaging, lighting and heating equipment, furnace components, etc., can solve the problems of low cell transport efficiency, achieve effective docking, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

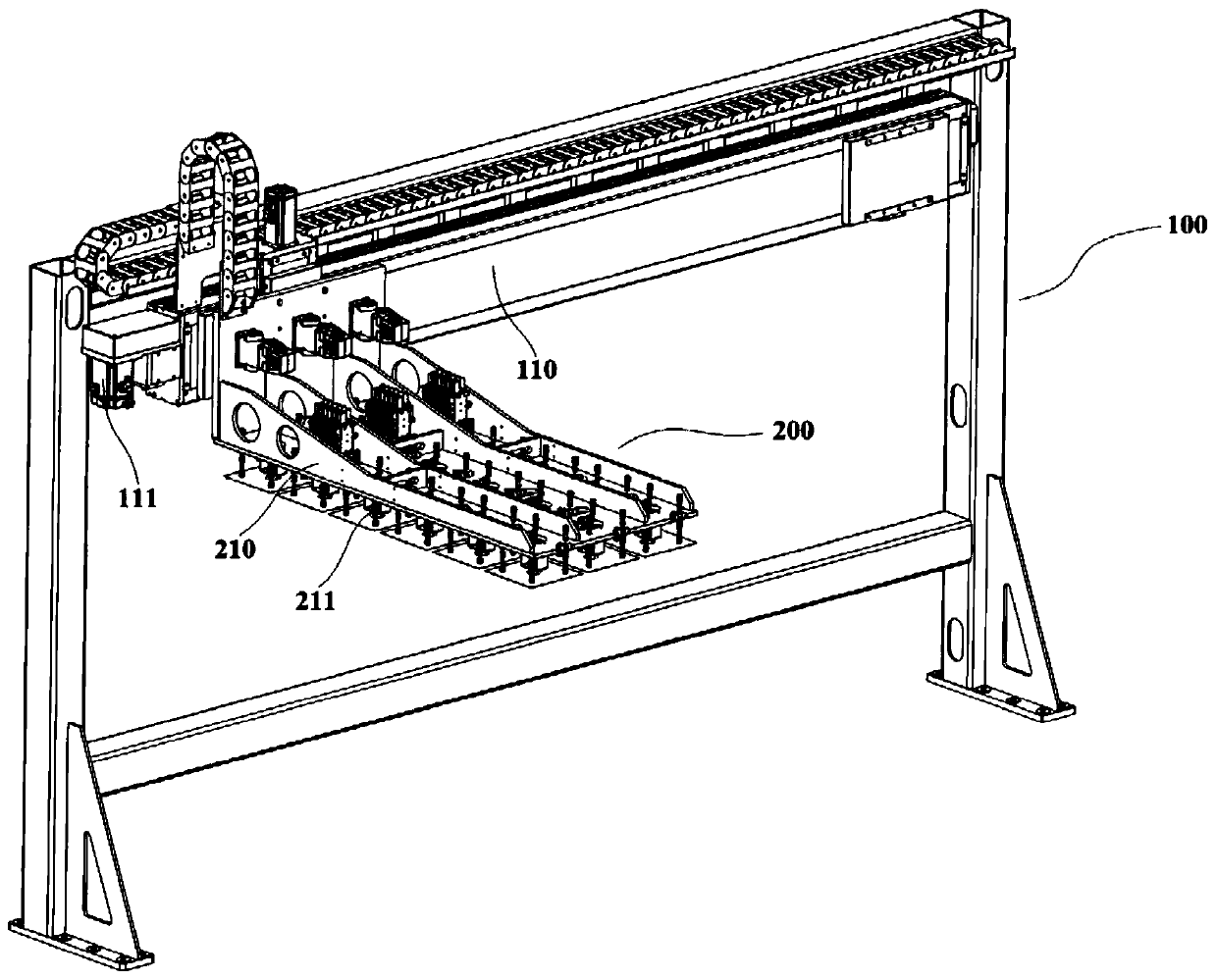

[0039] Combine figure 1 with image 3 , The multi-silicon wafer turning and positioning device of this embodiment includes a bracket 100, a suction cup lateral movement mechanism 200, and a shuttle board positioning and transmission mechanism 400. The bracket 100 is provided with a first sliding module 110 and a cell carrying mechanism 500. A sliding module 110 is used to drive the chuck transversal mechanism 200 to slide back and forth to the battery slice carrying mechanism 500 to grab the battery slices. The bottom of the suction cup traverse mechanism 200 is provided with a battery slice turning mechanism 300 for receiving battery slices. The turning mechanism 300 synchronously turns the received battery pack and makes it fall onto the shuttle positioning and transmission mechanism 400 for transportation.

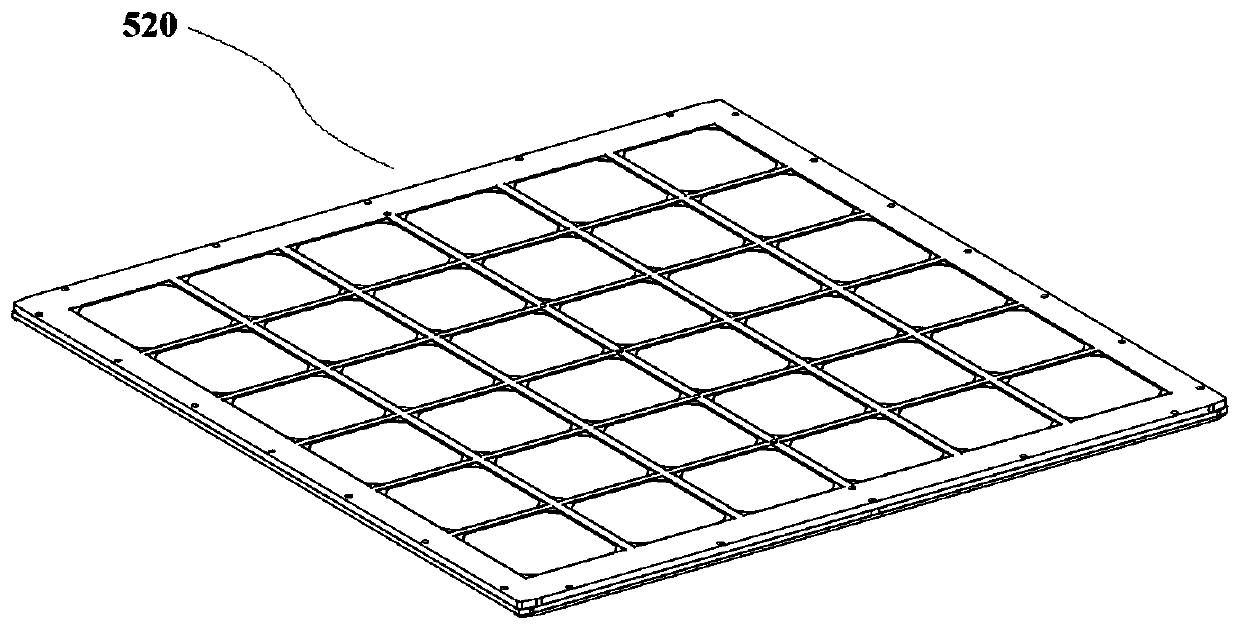

[0040] In this embodiment, the cell carrying mechanism 500 includes a carrier transport track 510 and a carrier 520 provided on the carrier transport track 510. The carrier...

Embodiment 2

[0047] The structure of a multi-silicon turning positioning device of this embodiment is basically the same as that of Embodiment 1. Further, the shuttle board positioning and transmission mechanism 400 in this embodiment includes a shuttle board lifting mechanism 410 and a driving shuttle board lifting mechanism 410 When the second sliding module 420 slides toward the battery piece turning mechanism 300, when the shuttle board lifting mechanism 410 slides to the bottom of the battery piece turning mechanism 300, the second vacuum suction cup 315 fails to vacuum to release the battery pieces.

[0048] Specifically, in this embodiment, the second sliding module 420 is driven by the second motor 422 provided on the shuttle board positioning transmission mechanism 400, and the second sliding module 420 drives the shuttle board lifting mechanism 410 to slide in the same direction as the first sliding mold. The sliding direction of the group 110 driving the suction cup traverse mechani...

Embodiment 3

[0051] The structure of a multi-silicon turning positioning device of this embodiment is basically the same as that of the second embodiment. Further, the positioning pin 412 in this embodiment is driven up and down by the cylinder 413 provided at the bottom of the shuttle board lifting mechanism 410. When the chip is placed on the silicon chip support plate 415, the air cylinder 413 retracts and the battery chip enters the positioning groove formed by the positioning pins 412.

[0052] In this embodiment, the silicon wafer support plate 415 is also provided with a graphite backing plate 414 for placing the battery pieces. The graphite backing plate 414 is arranged in an array on the silicon wafer support plate 415. Preferably, the graphite backing plate 414 is provided corresponding to each battery piece. , The graphite backing plate 414 can prevent the battery sheet from contacting other material parts to produce dirt, and play a role of isolation and protection for the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com