Red mud-based ceramsite concrete and preparation method and application thereof

A technology of ceramsite concrete and red mud, applied in cement production and other directions, can solve the problems of unfavorable development of circular economy, high consumption of ceramsite concrete resources and energy, and high cost, and achieve significant economic and environmental benefits, low cost of raw materials, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

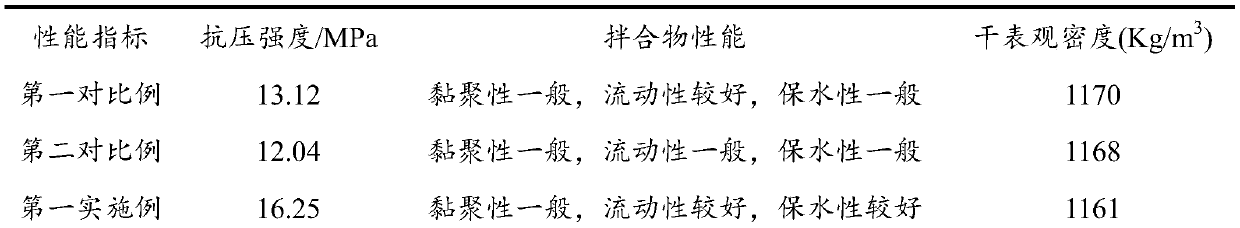

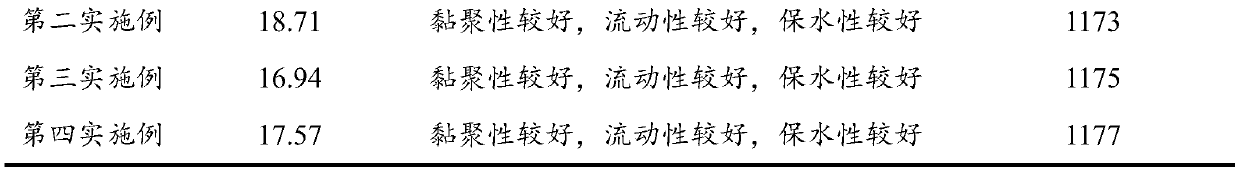

Examples

no. 1 example

[0056] A preparation method of red mud-based ceramsite concrete, comprising the steps of:

[0057] (1) Acidification treatment of fly ash: use industrial tail gas (the mass concentration of carbon dioxide is between 9% and 15%) to compound the solid waste of step (2) under the conditions of temperature 200°C, humidity 80%, and pressure 2.5MPa The solid waste was subjected to acidification treatment for 4 hours. After the completion, the solid waste complex was dried, ground, and passed through a 150-mesh sieve to obtain modified fly ash.

[0058] (2) Preparation of the gelling material: in parts by weight, 600 parts of red mud soup, 300 parts of mineral powder and 100 parts of modified fly ash were evenly mixed to obtain the gelling material.

[0059] (3) Preparation of red mud-based ceramsite: According to parts by weight, 300 parts of red mud, 500 parts of Portland cement, and 200 parts of water were uniformly mixed and granulated into balls, and naturally cured for 24 hours...

no. 2 example

[0063] A preparation method of red mud-based ceramsite concrete, comprising the steps of:

[0064] (1) Acidification treatment of fly ash: use industrial tail gas (the mass concentration of carbon dioxide is between 9% and 15%) to compound the solid waste of step (2) under the conditions of temperature 370°C, humidity 90%, and pressure 0.5MPa The solid waste was subjected to acidification treatment for 12 hours. After the completion, the solid waste complex was dried, ground, and passed through a 150-mesh sieve to obtain modified fly ash.

[0065] (2) Preparation of the gelling material: in parts by weight, 500 parts of red mud soup, 400 parts of mineral powder and 100 parts of modified fly ash were evenly mixed to obtain the gelling material.

[0066] (3) Preparation of red mud-based ceramsite: According to parts by weight, 270 parts of red mud, 500 parts of Portland cement, and 200 parts of water were uniformly mixed and granulated into balls, and naturally cured for 20 hour...

no. 3 example

[0070] A preparation method of red mud-based ceramsite concrete, comprising the steps of:

[0071] (1) Acidification treatment of fly ash: use industrial tail gas (carbon dioxide mass concentration between 9~15%) to treat the solid waste compound of step (2) under the conditions of temperature 80°C, humidity 60%, pressure 2MPa Carry out acidification treatment for 30 hours. After completion, the solid waste complex is dried, ground, and passed through a 150-mesh sieve to obtain modified fly ash.

[0072] (2) Preparation of gelling material: in parts by weight, 400 parts of red mud soup, 400 parts of mineral powder and 200 parts of modified fly ash were evenly mixed to obtain the gelling material.

[0073] (3) Preparation of red mud-based ceramsite: According to parts by weight, 280 parts of red mud, 500 parts of Portland cement, and 160 parts of water were uniformly mixed and granulated into balls, and naturally cured for 20 hours to obtain a particle size of 5 Red mud-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com