Transparent polyamide and preparation method thereof

A polyamide and polyamide salt technology, applied in the field of transparent polyamide and its preparation, can solve the problems of material toughness, touch, and size that are difficult to meet the requirements, achieve improvement and visibility, facilitate quantitative production, and process parameters are easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

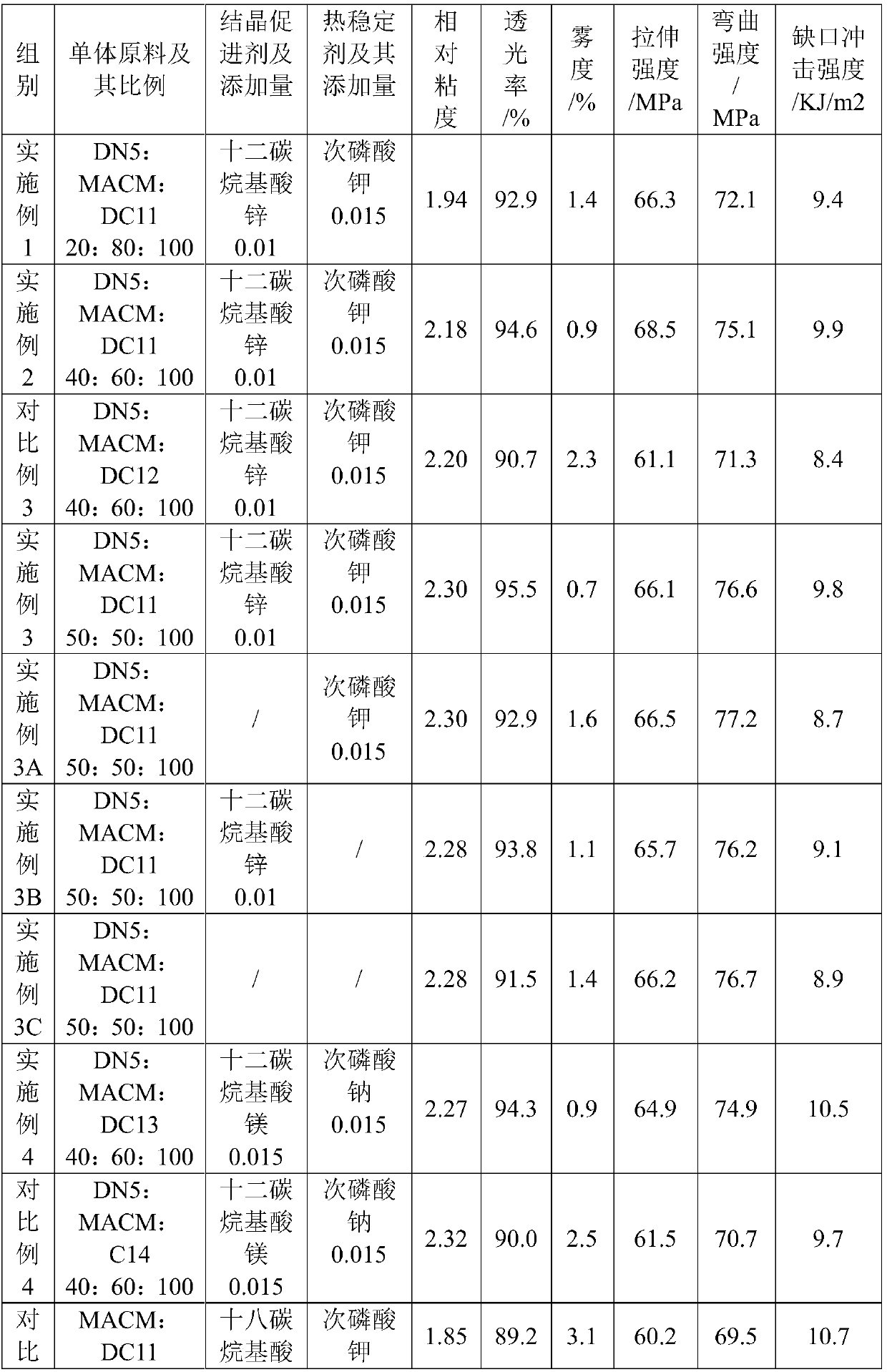

Examples

Embodiment 1

[0048] (1) Under nitrogen, mix 1,5-pentanediamine (DN5), MACM, undecanedibasic acid (DC11) and water evenly, and the molar ratio is DN5:MACM:DC11=20:80 : 100, the salt solution of 60% polyamide is obtained, wherein the salt weighs 20kg; then add 1,5-pentanediamine to adjust the pH value of the salt solution, so that the pH value when it is diluted to 10wt.% is 7.80, add Stabilizer potassium hypophosphite, the addition amount is 0.015 mole fraction;

[0049](2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.6Mpa, takes 1 hour and 20 minutes, exhausts, maintains the pressure, and maintains the pressure for 4 hours, and the temperature of the reaction system is 240 ° C when the pressure is completed. Reduce the pressure again to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), and the depressurization time is 50min. After the depressurization ends, the temperature of the reaction system is 263°C;

[0050] (3) The crysta...

Embodiment 2

[0053] (1) Under nitrogen, mix 1,5-pentanediamine (DN5), MACM, undecanedibasic acid (DC11) and water evenly, and the molar ratio is DN5:MACM:DC11=40:60 : 100, the salt solution of 60% polyamide is obtained, wherein the salt weighs 20kg; then add 1,5-pentanediamine to adjust the pH value of the salt solution, so that the pH value when it is diluted to 10wt.% is 7.80, add Stabilizer potassium hypophosphite, the addition amount is 0.015 mole fraction;

[0054] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.6Mpa, takes 1 hour and 20 minutes, exhausts, maintains the pressure, and maintains the pressure for 4 hours, and the temperature of the reaction system is 240 ° C when the pressure is completed. Reduce the pressure again to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), and the depressurization time is 50min. After the depressurization ends, the temperature of the reaction system is 263°C;

[0055] (3) The cryst...

Embodiment 3

[0058] (1) Under nitrogen, mix 1,5-pentanediamine (DN5), MACM, undecanedibasic acid (DC11) and water evenly, and the molar ratio is DN5:MACM:DC11=50:50 : 100, to prepare a 60% polyamide salt solution, wherein the salt weighs 20kg; then add 1,5-pentanediamine to adjust the pH value of the salt solution so that the pH value when it is diluted to 10wt.% is 7.85, Add stabilizer potassium hypophosphite in an amount of 0.015 mole fractions;

[0059] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.6Mpa, takes 1 hour and 20 minutes, exhausts, maintains the pressure, and maintains the pressure for 4 hours, and the temperature of the reaction system is 240 ° C when the pressure is completed. Reduce the pressure again to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), and the depressurization time is 50min. After the depressurization ends, the temperature of the reaction system is 263°C;

[0060] (3) The crystallization acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com