Cobalt-based metal organic framework material and application

An organic framework and metal-based technology, which is applied in the field of photocatalytic carbon dioxide reduction technology and energy conversion materials, can solve the problems of unclear structural components and difficult elucidation of active sites, and is conducive to large-scale production, easy to separate and wash Clean, Process-Effective Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

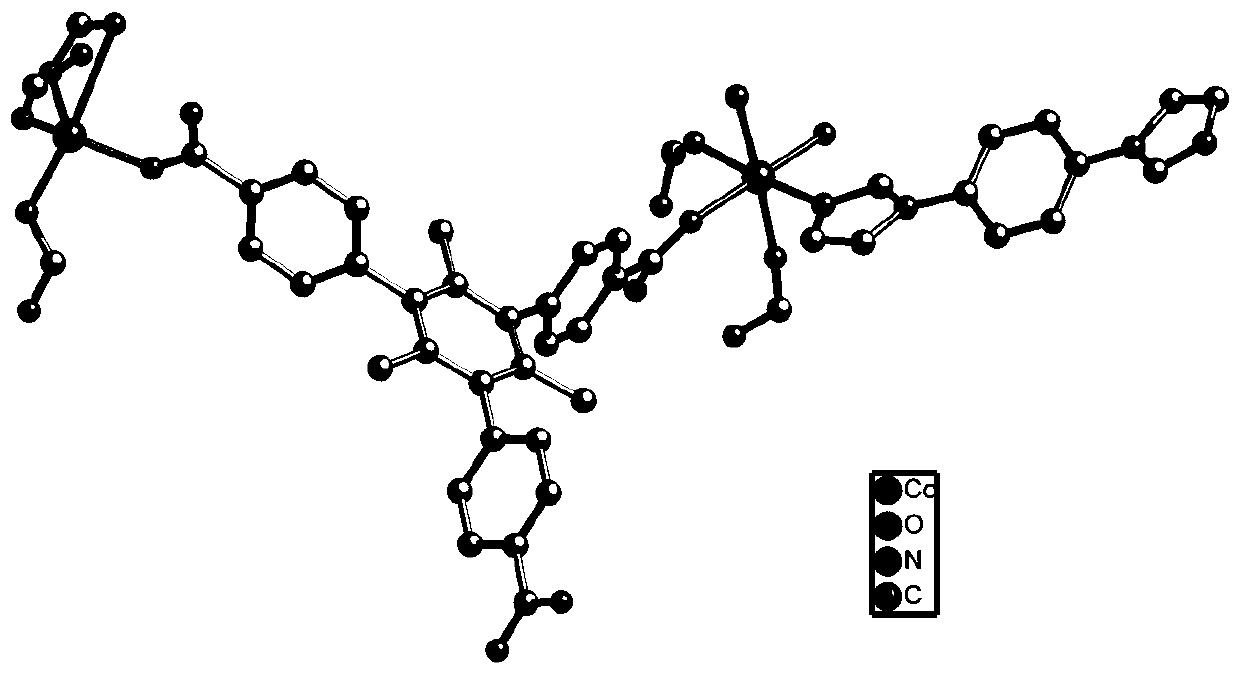

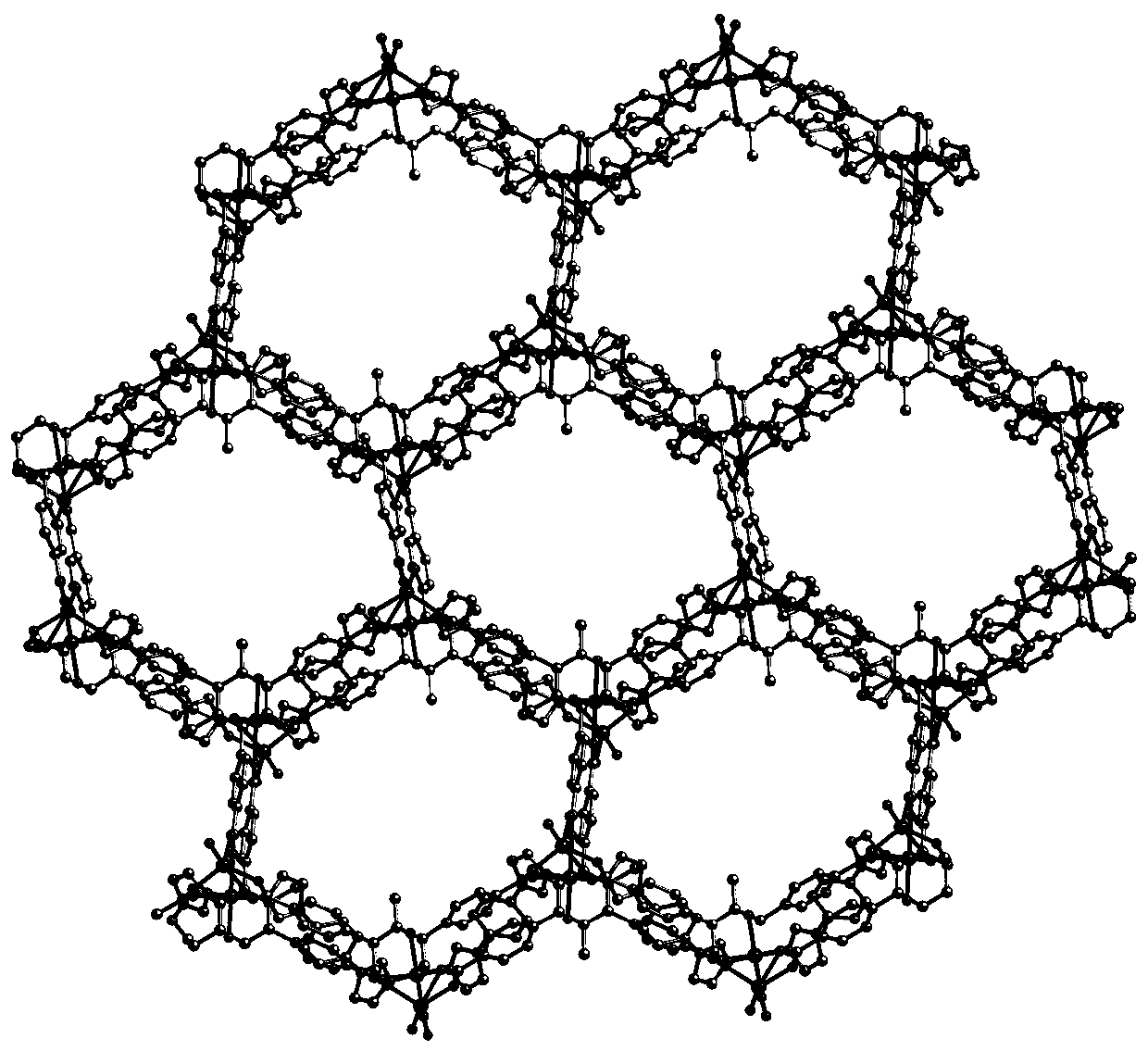

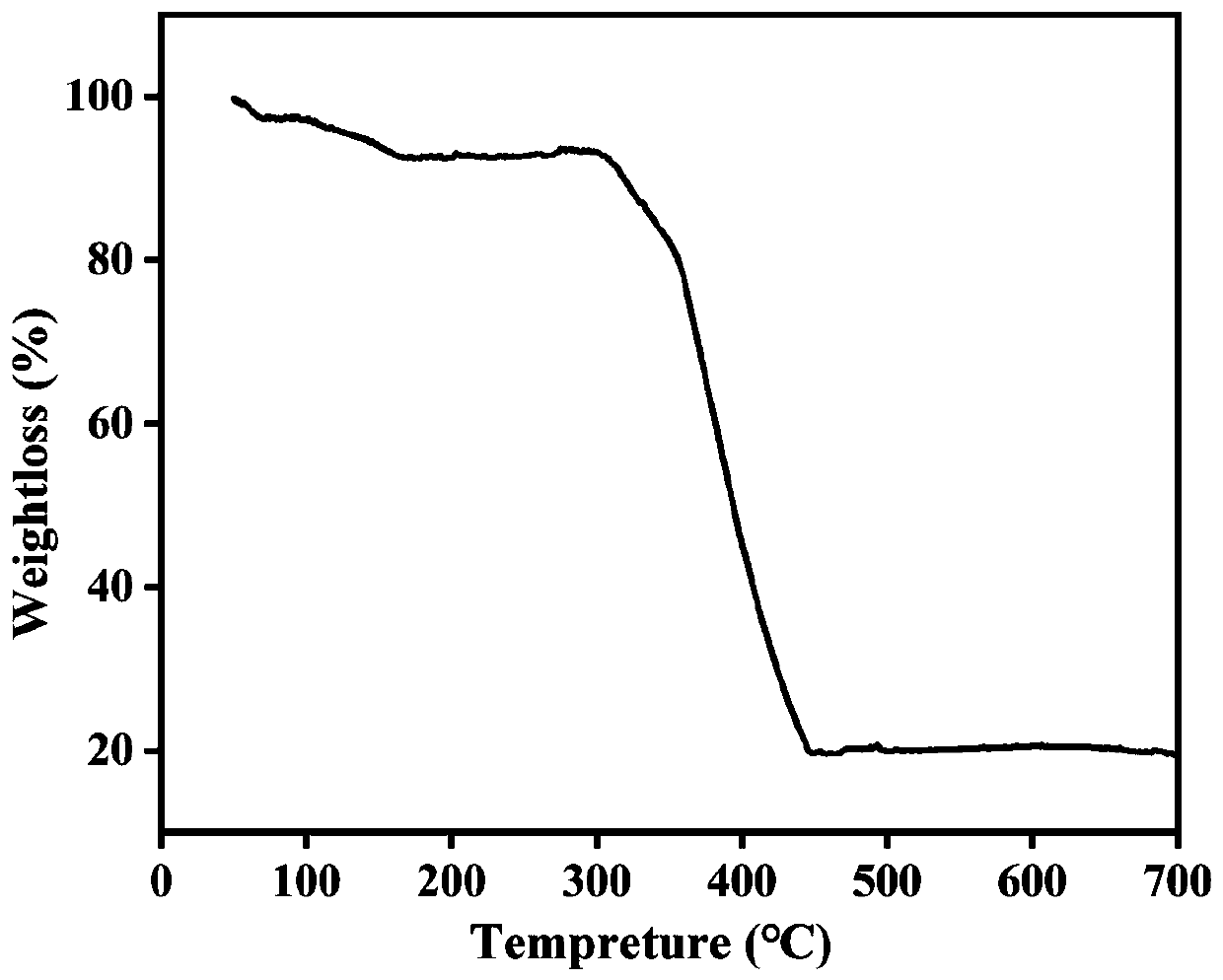

[0031] Take organic ligand 1,3,5-trimethyl-2,4,6-tricarboxyphenylbenzene 9.6 mg, 1,4-bis(1-imidazolyl)benzene 4.2 mg, cobalt perchlorate hexahydrate 14.6 mg mg was dissolved in 3.0 mL of N,N-dimethylformamide and 1.0 mL of deionized water, then 50 μL of fluoboric acid was added dropwise, ultrasonicated for 30 min, and reacted at a constant temperature of 140 °C for 72 h, and then removed Cool down to room temperature, wash and dry in vacuum to obtain blue transparent bulk crystals, that is, cobalt-based metal-organic framework (Co-MOF). Depend on Figure 1-2 It can be seen that metal cobalt ions adopt a six-coordination configuration in the material, and the entire structure belongs to a three-dimensional structure. Depend on image 3 It can be seen from the thermogravimetric diagram that the material is stable to 430 in air o C or so. For XRD test data, see Figure 4 , the powder diffraction peak of the prepared sample is highly consistent with the diffraction peak of th...

Embodiment 2

[0033] Take organic ligand 1,3,5-trimethyl-2,4,6-tricarboxyphenylbenzene 9.6 mg, 1,4-bis(1-imidazolyl)benzene 4.2 mg, cobalt perchlorate hexahydrate 14.6 mg mg was dissolved in 3.0 mL of N,N-dimethylformamide and 1.0 mL of deionized water, then 50 μL of fluoboric acid was added dropwise, ultrasonicated for 30 min, and reacted at a constant temperature of 120 °C for 72 h, and then removed Cool down to room temperature, wash and dry in vacuum to obtain blue transparent bulk crystals, that is, cobalt-based metal-organic framework (Co-MOF). After XRD inspection, the test data is consistent with the XRD of Example 1, which can prove that the obtained sample is a material with high purity.

Embodiment 3

[0035]Take organic ligand 1,3,5-trimethyl-2,4,6-tricarboxyphenylbenzene 9.6 mg, 1,4-bis(1-imidazolyl)benzene 4.2 mg, cobalt perchlorate hexahydrate 14.6 mg mg was dissolved in 3.0 mL of N,N-dimethylformamide and 1.0 mL of deionized water, then 50 μL of fluoboric acid was added dropwise, ultrasonicated for 30 min, and reacted at a constant temperature of 120 °C for 48 h, and then removed Cool down to room temperature, wash and dry in vacuum to obtain blue transparent bulk crystals, that is, cobalt-based metal-organic framework (Co-MOF). After XRD inspection, the test data is consistent with the XRD of Example 1, which can prove that the obtained sample is a material with high purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com