Testing device and testing method for corner sensor

A technology of a corner sensor and a testing device, which is applied in the direction of measuring devices, electrical devices, instruments, etc., can solve problems such as potential safety hazards, failure of electronic power steering systems, and increased driving burden for drivers, and achieves high installation accuracy and structural disassembly. Convenient, accurate angular velocity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

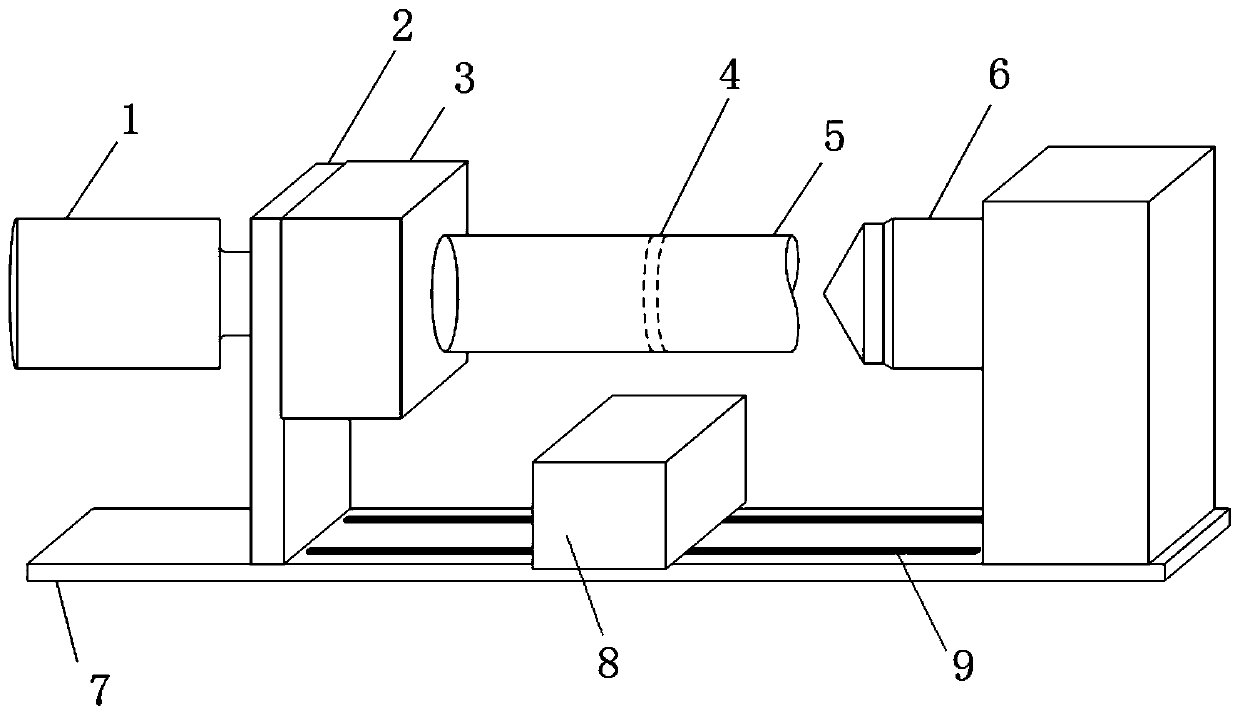

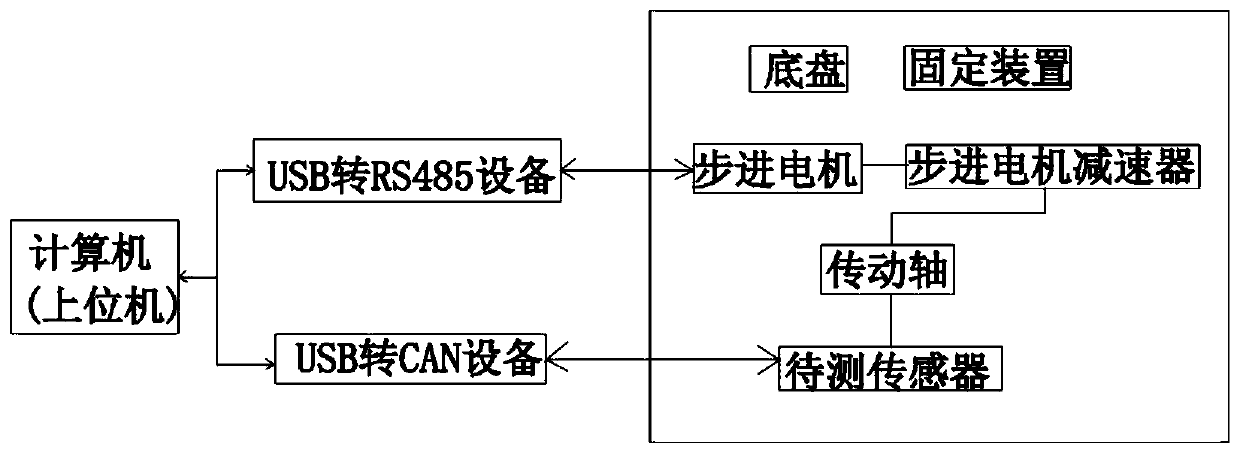

[0022] see Figure 1-Figure 6 As shown, the technical solution adopted in this specific embodiment is that it comprises a stepper motor 1, a bracket 2, a stepper motor reducer 3, a measured sensor installation position 4, a transmission shaft 5, a transmission shaft fixing device 6, a chassis 7, a sensor Fixing device 8, slide rail 9, the chassis 1 is a rigid structure supporting other parts, the top of the chassis 1 is provided with a slide rail 9, the sensor fixing device 8 is used to fix the sensor, the sensor fixing device 8 is connected with the slide rail 9, and the sensor is fixed The device 8 can slide along the slide rail 9 to ensure that the rotation axis of the sensor and the transmission shaft 5 are on the same straight line. The fixing method of the sensor fixing device 8 is a clamping fixing method, and its fixing method can make multiple sensors be fixed at the same time In this device, the test efficiency is improved without loss of accuracy. The stepper motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com