Aluminum alloy anode material for aluminum/air battery as well as preparation and application of aluminum alloy anode material

An anode material, air battery technology, applied in battery electrodes, fuel cell type half cells and primary cell type half cells, circuits, etc., to achieve the effects of high electrochemical activity, strong corrosion resistance and low cost

Active Publication Date: 2020-06-19

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The first object of the present invention is to provide a kind of aluminum alloy anode material for aluminum / air batteries in view of the problems existing in the existing aluminum alloy anode materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

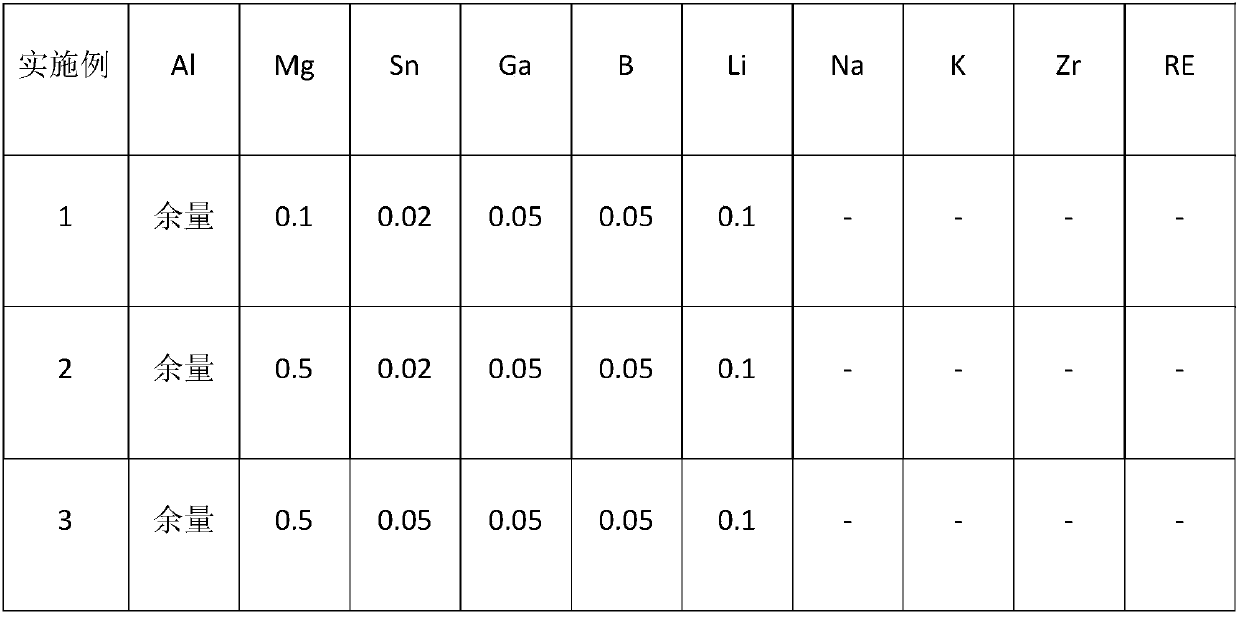

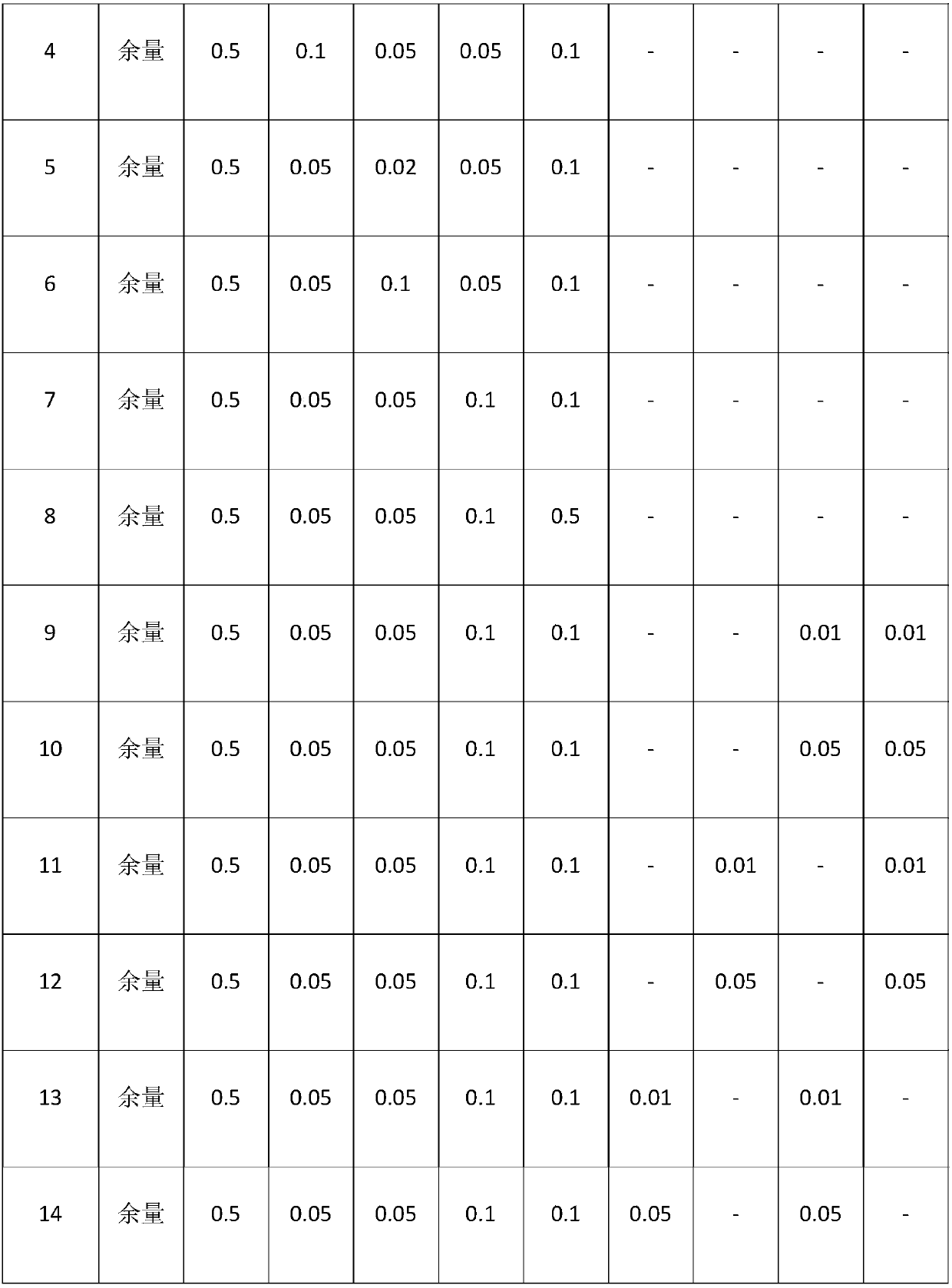

[0037] A series of aluminum alloy anode materials were prepared by the above method, and the specific composition is shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

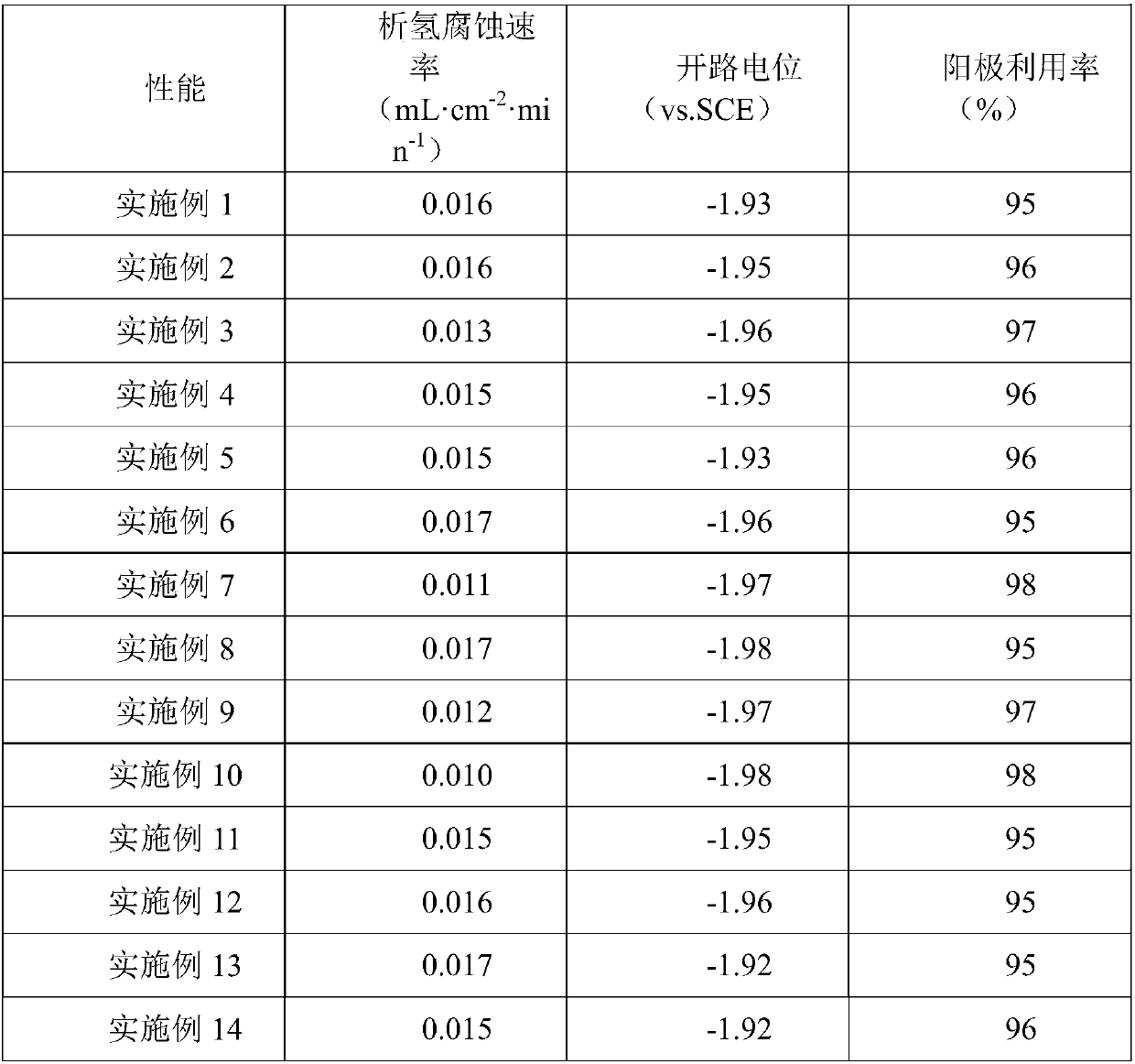

The invention discloses an aluminum alloy anode material for an aluminum / air battery and a preparation method of the aluminum alloy anode material. The aluminum alloy anode material mainly comprises several or more of the following components: 0.1 to 1.0 wt% of Mg, 0.01 to 0.9 wt% of Sn, 0.01 to 0.1 wt% of Ga, 0.01 to 0.5 wt% of Li, 0.01 to 0.5 wt% of B, 0.0 to 0.1 wt% of Na, 0.0 to 0.1 wt% of K,0.0 to 0.1 wt% of Zr, 0.0 to 2.0 wt% of RE, and the balance Al. The aluminum alloy anode material is excellent in corrosion resistance in alkaline electrolyte and good in electrochemical activity, thehydrogen evolution corrosion rate is smaller than or equal to 0.017 mL.cm<-2>.Min<-1>, the open-circuit potential is smaller than or equal to -1.92 V (vs.SCE), and the anode utilization rate is larger than or equal to 95%. The aluminum alloy anode material has the advantages of excellent comprehensive performance, simple preparation and the like.

Description

technical field [0001] The invention belongs to the field of metal / air fuel cells, and specifically relates to an aluminum alloy anode material for an aluminum / air cell and a preparation method thereof. Background technique [0002] The metal / air fuel cell is a new type of green battery with metal as the anode material and air as the cathode material. It has the advantages of low price, high energy density, and no pollution from the reaction product. Metal aluminum electrode potential is negative (alkaline medium -2.35Vvs.SHE), mass specific capacity is high (2.98Ah g -1 ), rich in resources, so aluminum / air batteries have good application prospects. [0003] Aluminum / air battery is a new type of high specific energy battery, the actual specific energy can be as high as 300~400Wh·kg -1 . However, metal aluminum has the following problems as an anode: a layer of oxide film on the aluminum surface inhibits electrochemical activity; aluminum will undergo severe hydrogen evol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/88H01M4/90H01M12/06

CPCH01M4/8825H01M4/9041H01M12/06

Inventor 王二东高山山高建新孙公权

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com