Narrow linewidth distributed feedback semiconductor laser and preparation method thereof

A distributed feedback and laser technology, which is applied to the structure of semiconductor lasers, lasers, and optical waveguide semiconductors, can solve problems that cannot meet the application requirements, and achieve the effects of stabilizing the working wavelength, narrowing the laser line width, and reducing the line width factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

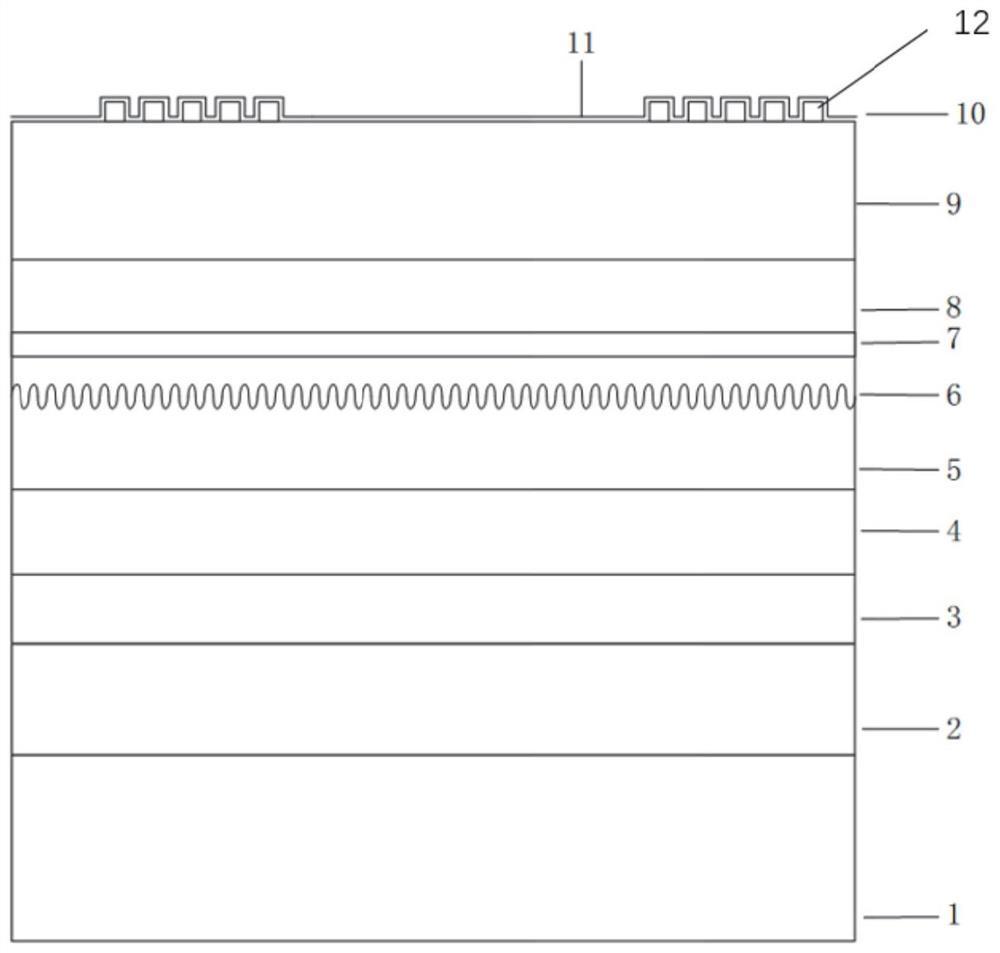

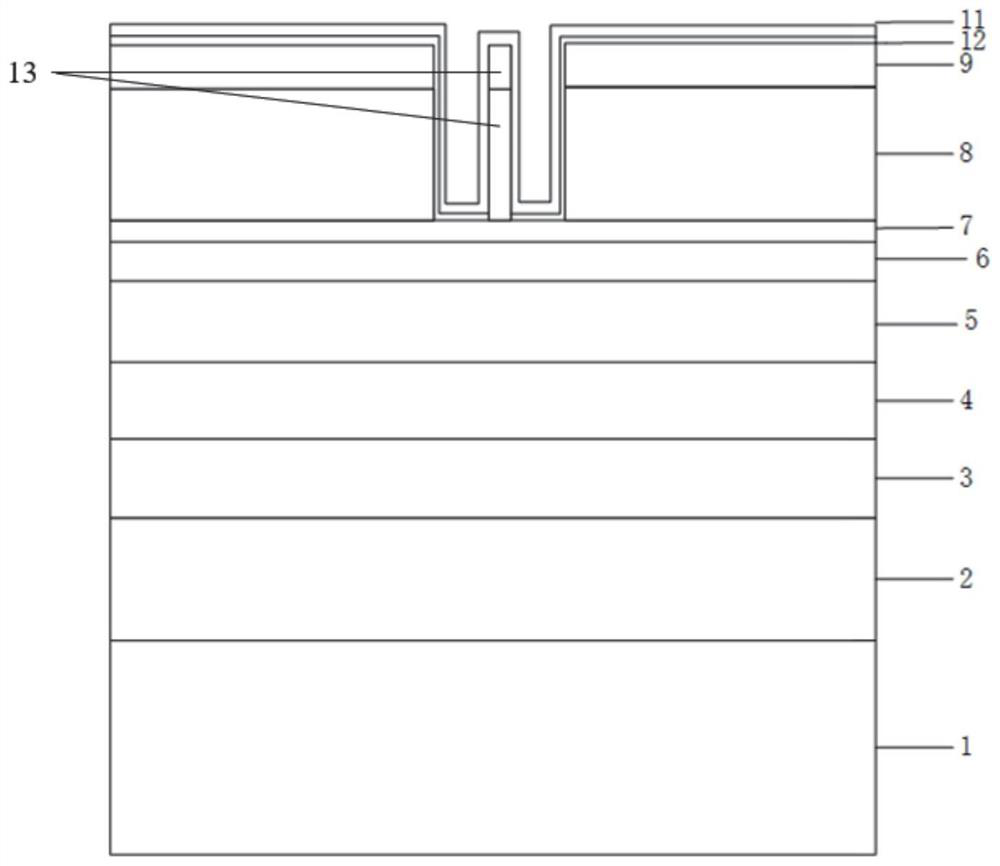

[0041] The invention proposes a feedback semiconductor laser with narrow line width distribution and a two-layer grating structure. The distributed feedback grating includes a secondary epitaxial distributed feedback grating near the active area and an electrode sampling grating composed of periodic ohmic contacts of electrodes. Specifically, the chip structure of the laser includes an N-face electrode layer, a substrate layer, a buffer layer, a lower waveguide layer, an active layer, an upper waveguide layer, a secondary epitaxial grating layer, an etching self-stop layer, and a wrapping layer from bottom to top. layer, ohmic contact layer, passivation layer and P-side electrode layer. The cladding layer and the ohmic contact layer form a waveguide structure, and the waveguide structure is a ridge waveguide structure, and the grating structure of the laser includes a secondary epitaxial grating and an electrode sampling grating. The light-emitting surface of the laser has an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com