Tokamak ohm heating coil control system and method

An ohmic heating and tokamak technology, applied in electrical components, plasma, etc., can solve the problems of circulating current mode operation, uncontrollable current zero-crossing time, control time delay, etc., to achieve precise control, good portability, The effect of stable and efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] This application includes the following:

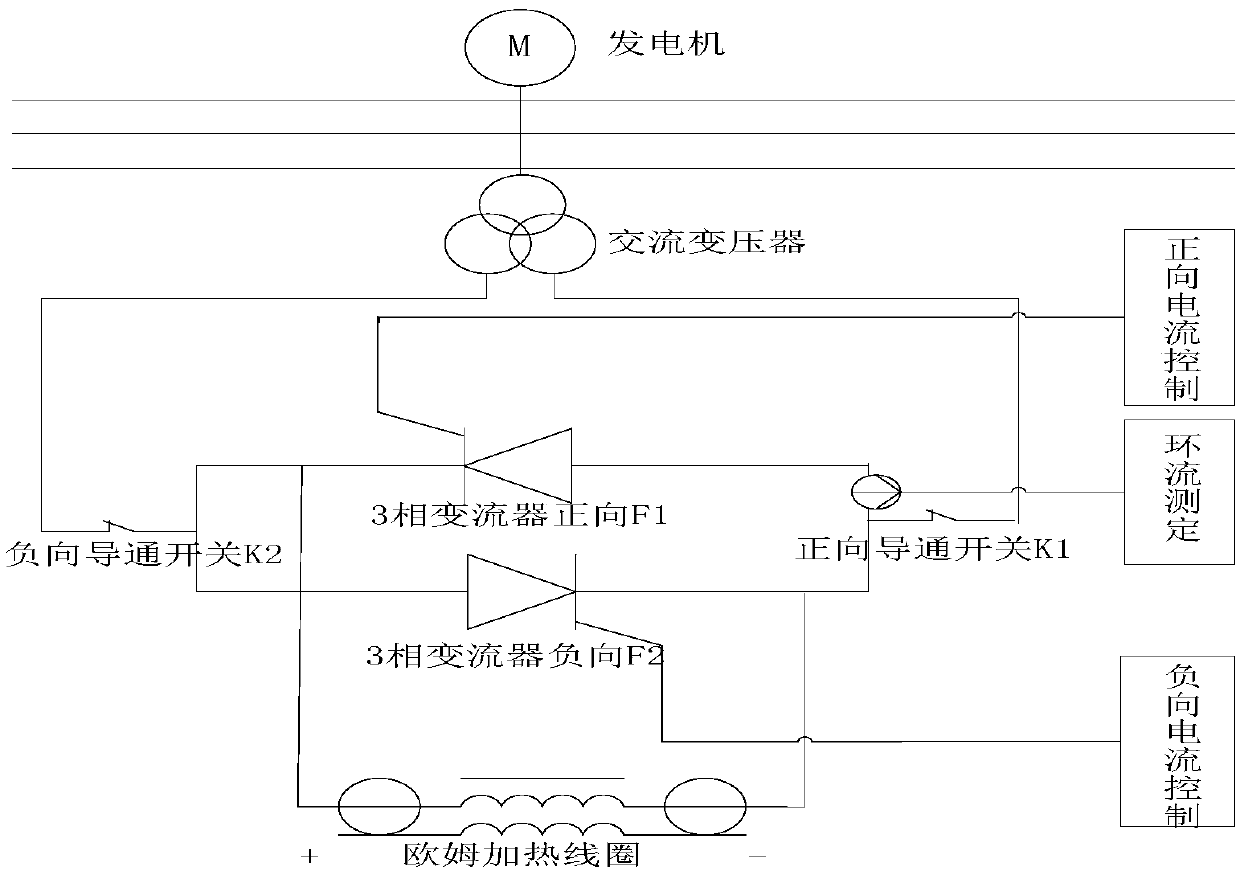

[0034] The power supply structure of the tokmak ohmic heating coil adopts an energy storage generator, an AC isolation transformer, a positive conducting switch K1, a negative conducting switch K2 and two sets of three-phase converters (F1, F2) connected in antiparallel to the ohmic The heating coil is powered.

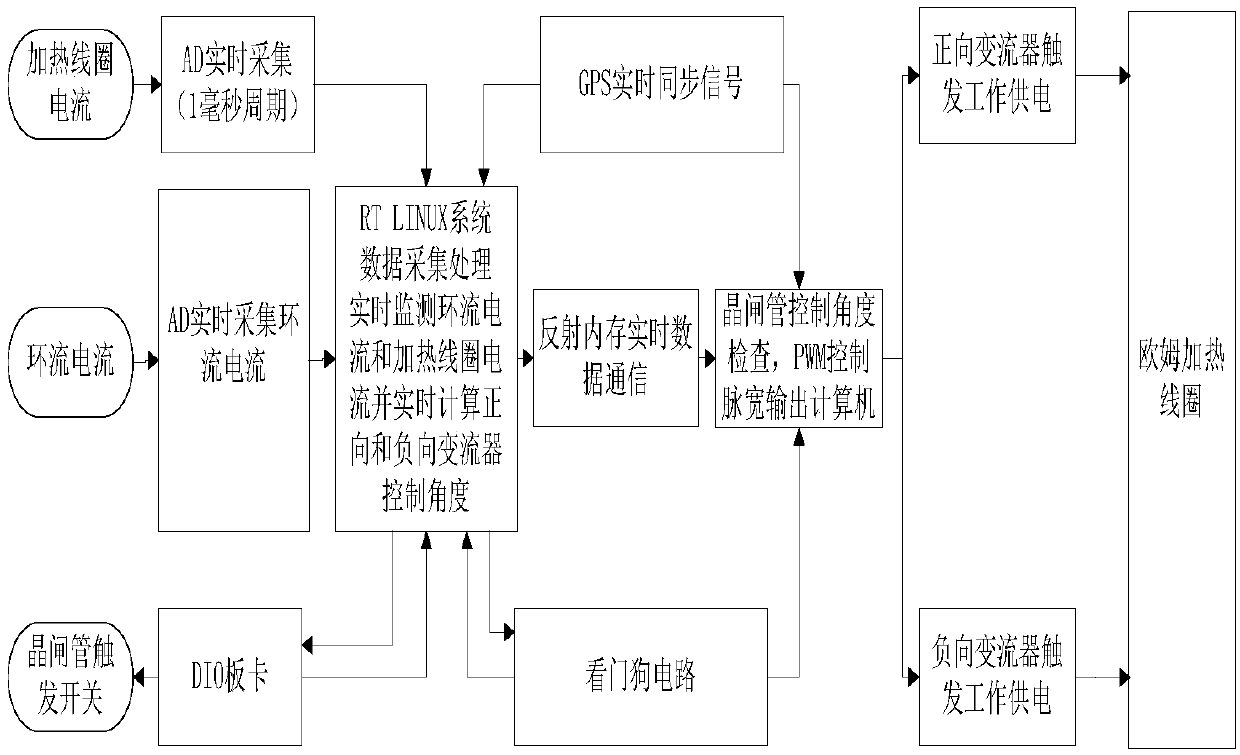

[0035] GPS (such as figure 2 ) The synchronous clock provides 10M precise clock signals for different control devices in the control system of the entire ohmic heating coil to meet the accuracy requirements of time and clock during the coil magnetization and inversion process, and reduce the system time delay.

[0036] The real-time controller regularly reports to the watchdog (such as figure 2) to send a 1 millisecond pulse to monitor the operating status of the system in real time to prevent the safety problem of the control system caused by the computer crash and ensure the normal operation of the entire system....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com