Multi-tower parallel type drying and purifying process and device

A purification device and parallel technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of large equipment footprint, high manufacturing cost, and inability to achieve dew point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

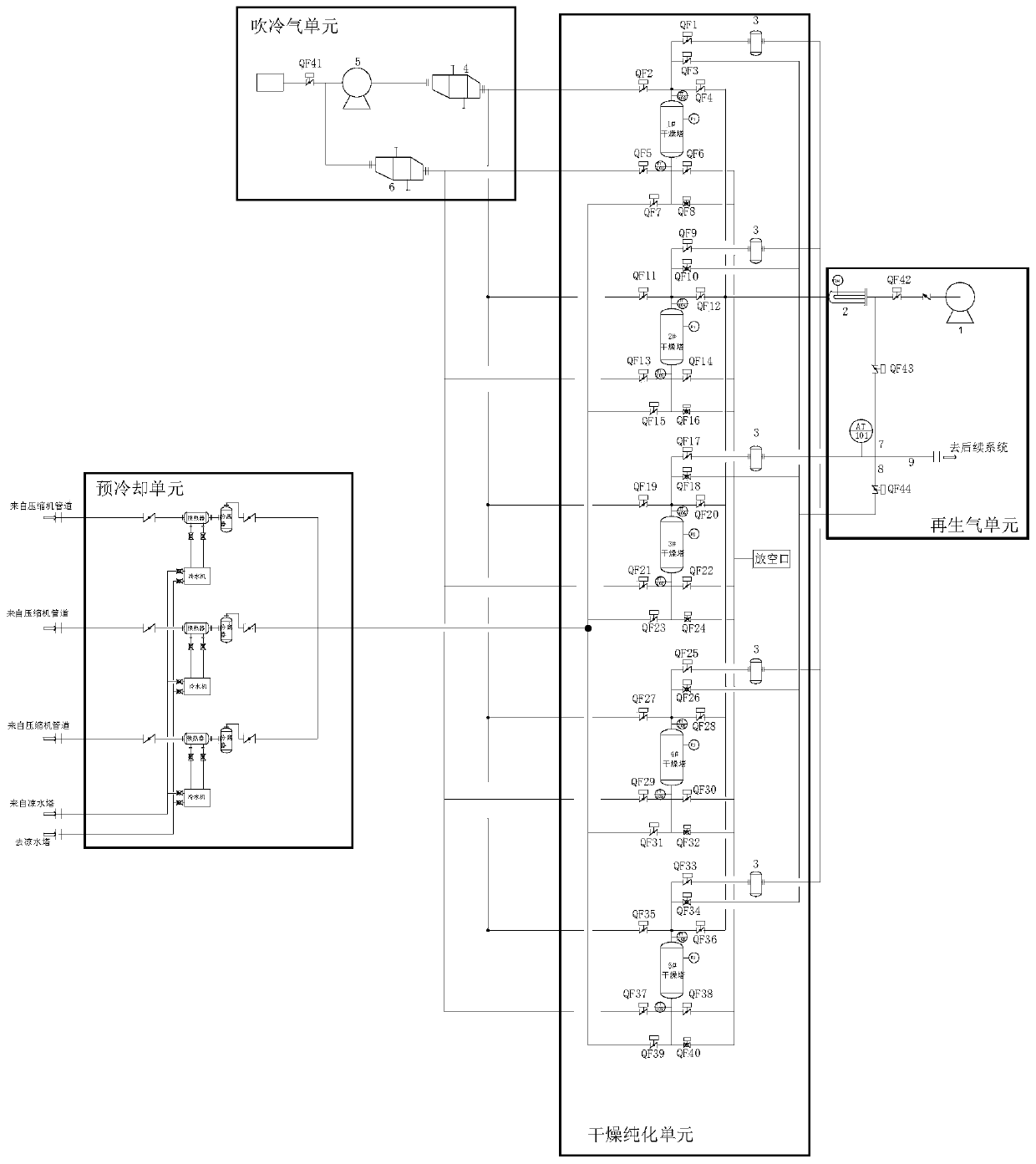

[0133] Embodiment one (with reference to figure 1 ):

[0134] Step 1: 1# drying tower, 2# drying tower, 3# drying tower form the adsorption group, 4# drying tower and 5# drying tower form the regeneration group; 4# adsorption tower and 5# adsorption tower are in a dry state before starting; The regeneration group is equipped with the first blower 1 (heating blower) and the second blower 5 (cooling blower); a set of regeneration air unit (also can adopt multiple sets in other embodiments), a set of air blowing unit (in other embodiments Multiple sets can also be used).

[0135] Step 2: The first round of adsorption and regeneration:

[0136] 2.1] 0-1 / 3 saturated adsorption time:

[0137] 1# drying tower, 2# drying tower and 3# drying tower are in adsorption purification, 4# drying tower and 5# drying tower are waiting for conversion;

[0138] The raw material gas passes through the pre-cooling unit, after being cooled by the pre-cooling unit, the solid particles and liquid ...

Embodiment 2

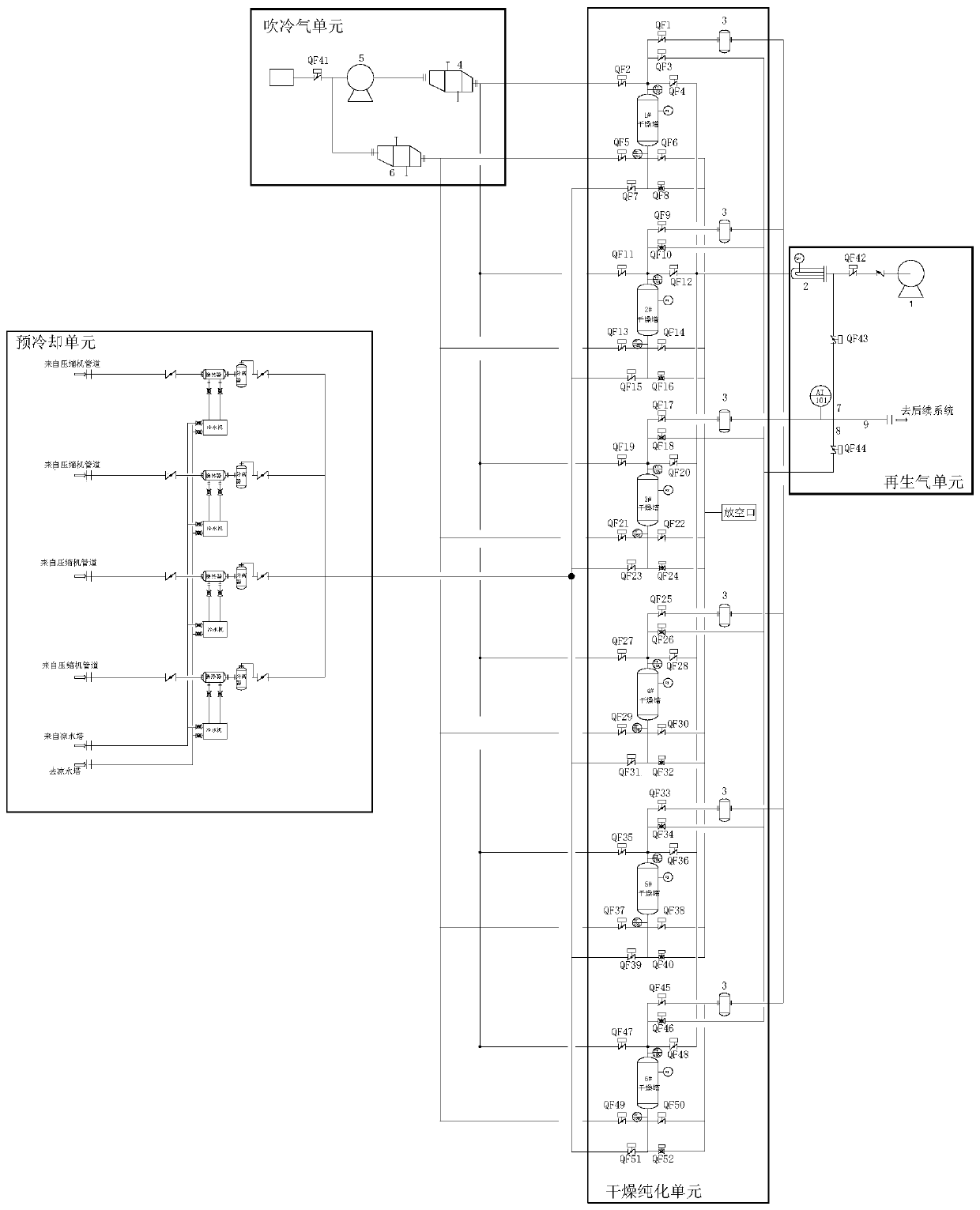

[0188] Embodiment two (with reference to figure 2 ):

[0189]Step 1: 1# drying tower, 2# drying tower, 3# drying tower, 4# drying tower form the adsorption group, 5# drying tower and 6# drying tower form the regeneration group; before starting, 5# adsorption tower and 6# adsorption tower In a dry state; the regeneration group is equipped with a first air blower 1 (heating air blower) and a second air blower 5 (cooling air blower); a set of regeneration air unit (multiple sets can also be used in other embodiments), a set of air blower unit (multiple sets can also be used in other embodiments).

[0190] Step 2: The first round of adsorption and regeneration:

[0191] 2.1] 0-1 / 4 saturated adsorption time:

[0192] 1# drying tower, 2# drying tower, 3# drying tower, 4# drying tower are in adsorption purification, 5# drying tower and 6# drying tower are waiting for conversion;

[0193] The raw gas passes through the pre-cooling unit, after being cooled by the pre-cooling unit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com