An integrated device for mixing and displacing two fluids and its application method

A technology of fluid mixing and mixing tanks, which is applied in the direction of fluid mixers, chemical instruments and methods, mixers, etc., and can solve problems such as inability to configure mixed fluids, limitations of device simulation functions, and high cost of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

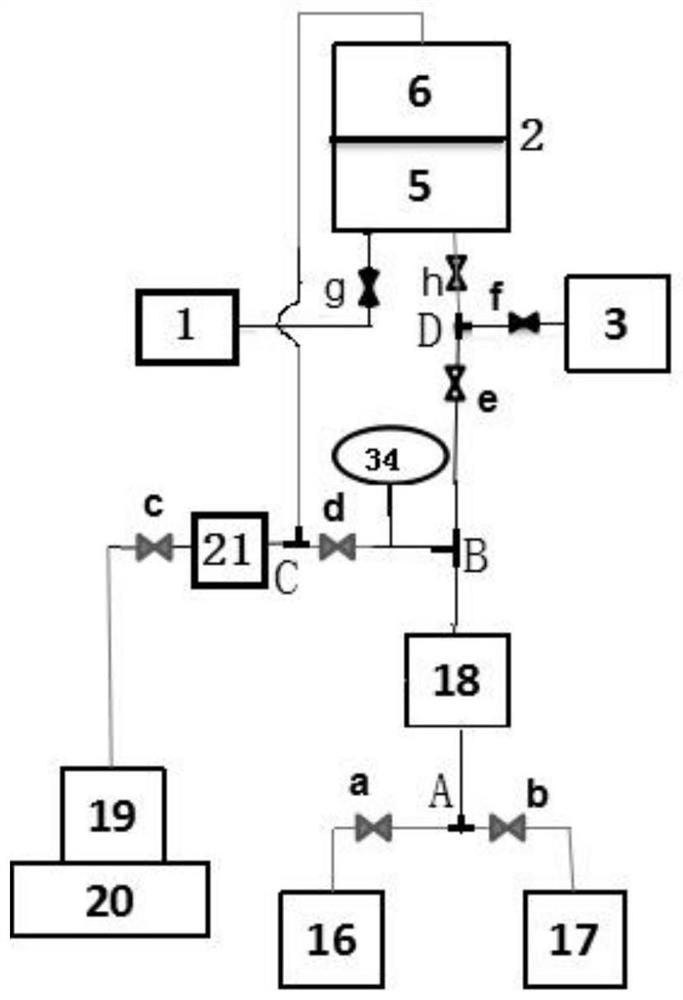

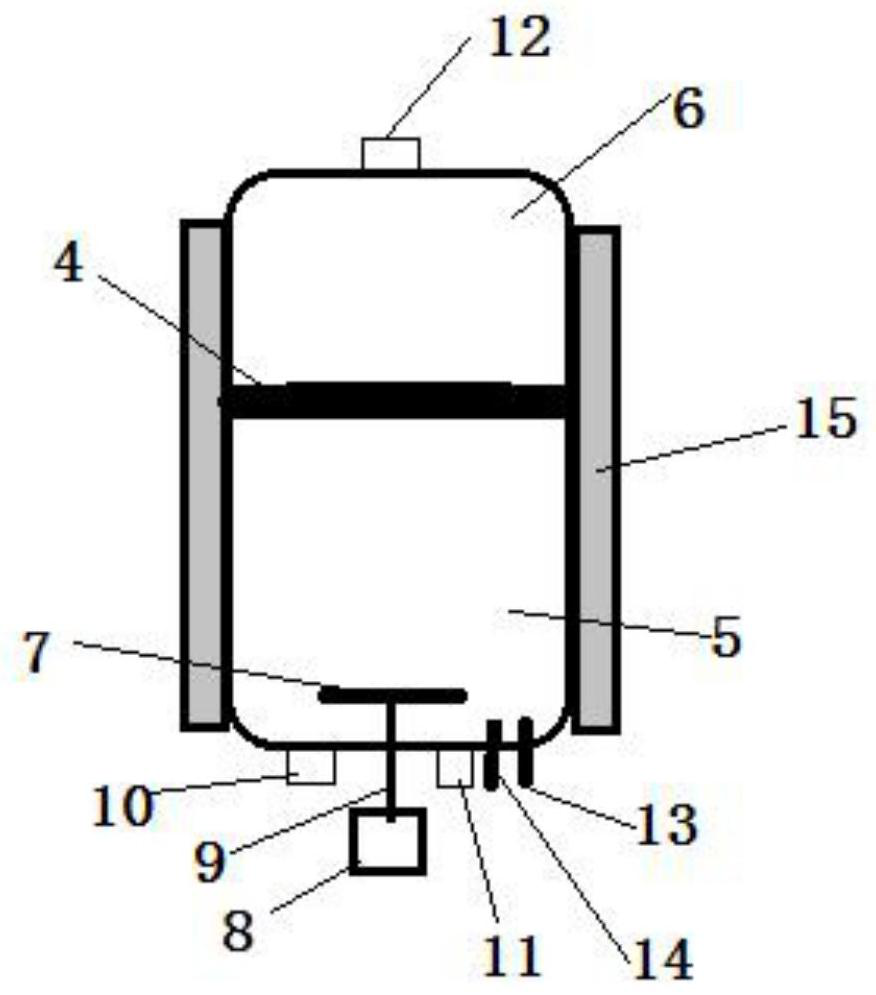

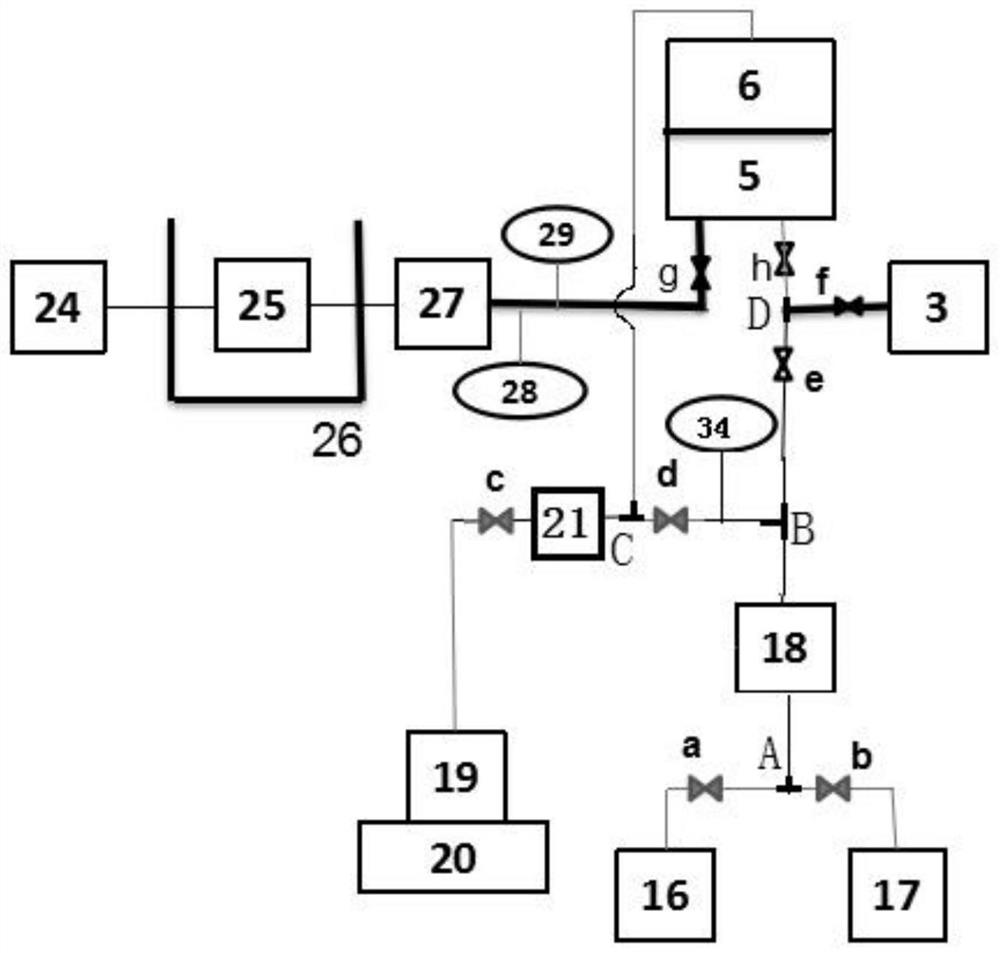

[0031] Such as figure 1 and 2 As shown, the integrated device for mixing and displacing two fluids provided by the present invention includes an auxiliary fluid delivery unit 1 , a working fluid delivery unit, and a mixing tank 2 . The auxiliary fluid delivery unit and the working fluid delivery unit respectively pump the auxiliary fluid and the working fluid into the mixing tank for mixing, and then drive the obtained mixed solution to the subsequent experimental testing device 3 . The auxiliary fluid delivery unit pumps liquid, gaseous or supercritical fluid into the mixing tank. Subsequent experimental testing devices can be plunger rock sample holders, high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com