One-hundred-percent inspection process and device for flywheel sensor holes

A sensor hole and sensor technology, which is applied in the program control of the sequence/logic controller, manufacturing tools, boring/drilling, etc., can solve the problems of axial height difference, low production efficiency, and out-of-tolerance angle, etc. To achieve the effect of reducing quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings. Those skilled in the art should understand that the following does not constitute a limitation to the protection scope of the present invention.

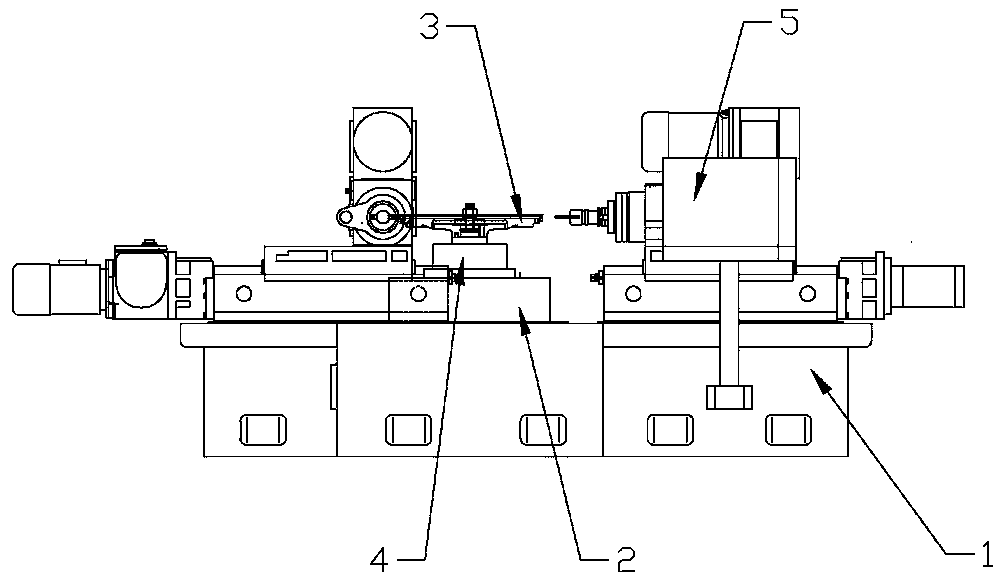

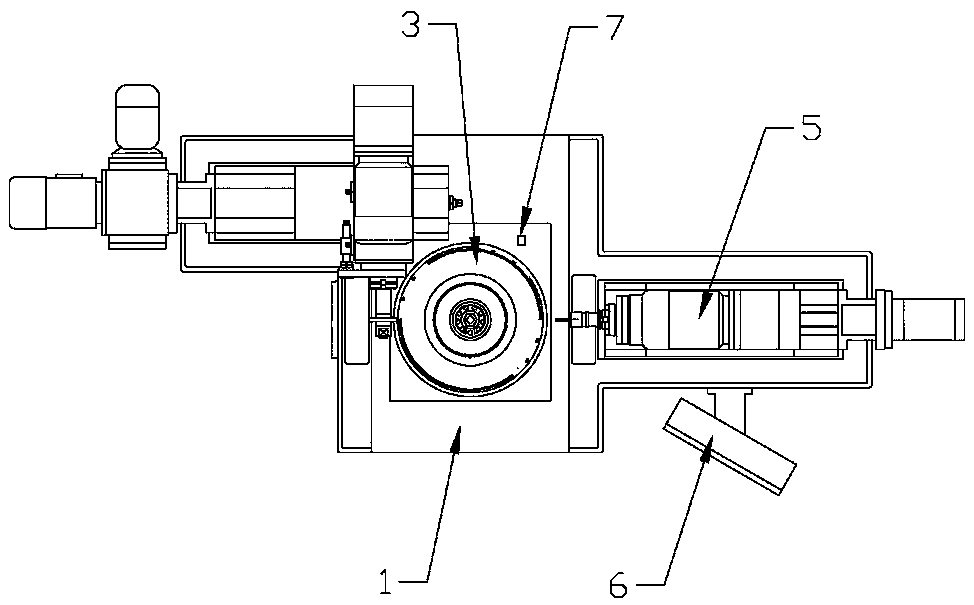

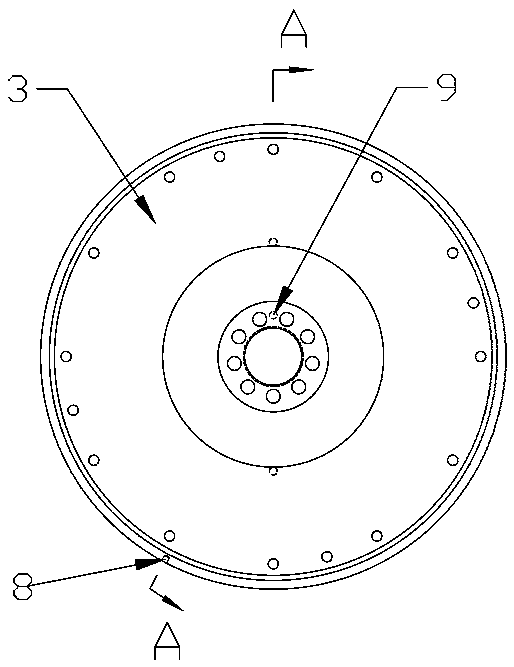

[0031] Examples such as Figure 1-4 As shown, a flywheel sensor hole inspection process, the device for implementing the process is a sensor hole processing device, the sensor hole processing device includes a base 1, a rotary table 2 is provided on the base 1, and a rotary table 2 is provided for The fixture 4 for fixing the flywheel 3 is provided with a drilling device 5 for processing sensor holes, a PLC industrial computer 6 and a display screen on the base 1, and a detection device is provided on the rotary table 2, and a signal collection sensor is provided on the detection device 7. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com