Flexible surface artificial board decorated with wood aesthetic elements

A flexible surface, man-made panel technology, used in the joining of wooden veneers, impregnating wood, manufacturing tools, etc., can solve the market demand that cannot meet the ever-changing decoration materials and the personalized and differentiated decoration styles, the decorative patterns are monotonous, Bump and crack and other problems, to achieve the effect of promoting sustainable development, feeling soft, flexible and elastic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention is a flexible surface wood-based panel decorated with wooden beauty elements, which can improve the surface decoration of the existing wood-decorated wood-based panels and overcome the surface brittleness. Its preparation method comprises the following specific operation steps:

[0041] 1. Extract the aesthetic elements of wood

[0042] The operation steps are: ①Material selection and sampling: Select 1 section of wood with obvious structural characteristics, and cut a piece of height (axial) x width (chord direction) x thickness (radial) from the selected wood section, which is about 20x20x20mm 2. Slicing: cut wood slices with a thickness of 0.02-2mm from the above wood samples; 3. Slice dehydration: The dehydration method is to use alcohol to immerse the wood slices from low concentration to high concentration step by step, and finally use anhydrous Soak in alcohol until completely dehydrated, and store the dehydrated sections in xylene; ④ secti...

Embodiment 1

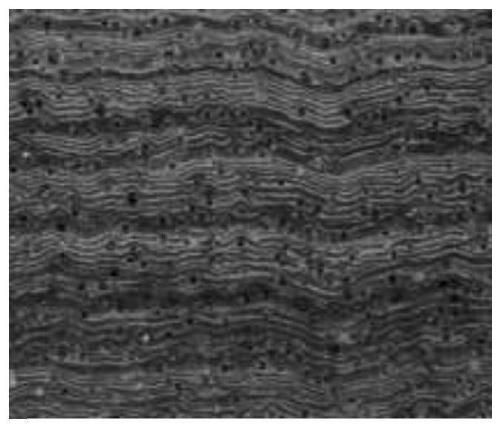

[0051]Take a section of large fruit red sandalwood wood, and cut a wood block with an axial x chord direction x radial direction of 20x20x20mm on the wood section; first cut the cross section of the wood block flat and smooth, and then cut a cross section slice with a thickness of about 2mm ; Soak the wood flakes in 50%, 70%, 80%, 90%, 95% and 100% alcohol for 60, 30, 20, 15, 10 and 5 minutes respectively, and then put Put the wood slices into xylene and let stand for 1 day; use Canadian neutral resin glue to fix the wood slices on the glass slide, observe the surface of the wood slices under a stereo photography microscope, and photograph the cross-section of the large-fruited rosewood wood at a magnification of 20 times. Original image; use PS image processing software on the computer to analyze the original image, and intercept a part of it as wood aesthetic elements, such as figure 1 shown.

[0052] by figure 1 The wood aesthetic elements shown are the material. After ap...

Embodiment 2

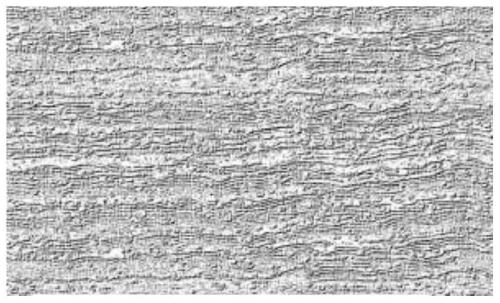

[0056] Take a section of silver fir wood, and cut a wood block with an axial x chord direction x radial direction of 20x10x10mm from the wood section; first cut the radial section of the wood block to make it smooth, and then cut a radial section of about 1mm thick. ; Soak the wood flakes in 50%, 70%, 80%, 90%, 95% and 100% alcohol for 40, 30, 20, 15, 10 and 5 minutes respectively, and then put Put the wood slices into xylene and let them stand for 1 day; fix the wood slices on the stage of the scanning electron microscope with conductive glue, observe the surface of the wood slices under the scanning electron microscope, and photograph the radial section of silver fir wood at a magnification of 1000 times. The original image; PS image processing software is applied on the computer to analyze the original image, and a part of it is intercepted as wood aesthetic elements, such as Figure 5 shown.

[0057] by Figure 5 The wood aesthetic elements shown are the material, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com