Coating protective material and preparation method thereof

A technology for protecting materials and coatings, applied in the field of materials, can solve problems such as cumbersome processes, difficult repairs, high labor costs, etc., and achieve the effect of simple operation process, convenient and simple maintenance, and easy mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

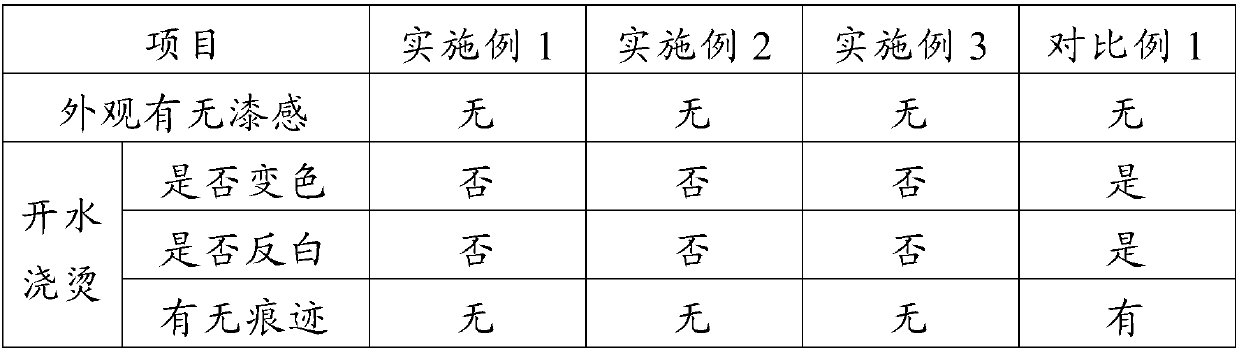

Examples

Embodiment 1

[0026] The present embodiment provides a coating protection material, comprising the following raw materials:

[0027] 15g palm wax, 30g zinc stearate, 15g microcrystalline wax, 20g tea seed oil, 30g triethanolamine, 25g Tween 80, 15g Tween 20, 80g gum arabic powder, 40g diatomaceous earth, 25g paraben Ester, 20g methylparaben, 20g ethylparaben, 30g organic bentonite, 35g urea-formaldehyde resin, 40g polyethylene wax, 120gEEA resin, 40g chlorinated polyethylene, 80g chlorinated polypropylene, 220g water-soluble amino resin, 80g alkyd resin, 60g propylene glycol, 300g deionized water, 90g OP-10, 80g OP-4.

[0028] The preparation method of above-mentioned coating protective material, comprises the following steps:

[0029] (1) Mix palm wax, microcrystalline wax and tea seed oil according to the proportion and heat to 80°C to obtain mixture I;

[0030] (2) Zinc stearate, triethanolamine, and Tween 80 were mixed according to the proportion and heated to 30°C to obtain mixture I...

Embodiment 2

[0043] The present embodiment provides a coating protection material, comprising the following raw materials:

[0044] 10g palm wax, 20g zinc stearate, 20g microcrystalline wax, 15g tea seed oil, 10g triethanolamine, 15 Tween 80, 10g Tween 20, 50 gum arabic powder, 20 diatomaceous earth, 15g paraben Ester, 10g methylparaben, 30g ethylparaben, 20g organic bentonite, 20g urea-formaldehyde resin, 20g polyethylene wax, 80g EEA resin, 20g chlorinated polyethylene, 50g chlorinated polypropylene, 150g water-soluble amino resin , 50g alkyd resin, 50g propylene glycol, 200g deionized water, 60g OP-10, 50g OP-4.

[0045] The preparation method of above-mentioned coating protective material, comprises the following steps:

[0046] (1) Mix palm wax, microcrystalline wax and tea seed oil according to the proportion and heat to 75°C to obtain mixture I;

[0047] (2) Zinc stearate, triethanolamine, and Tween 80 were mixed according to the proportion and heated to 27°C to obtain mixture II;...

Embodiment 3

[0060] The present embodiment provides a coating protection material, comprising the following raw materials:

[0061] 20g palm wax, 40g zinc stearate, 10g microcrystalline wax, 30g tea seed oil, 50g triethanolamine, 30g Tween 80, 20g Tween 20, 100g gum arabic powder, 60g diatomaceous earth, 30g paraben Ester, 25g methylparaben, 10g ethylparaben, 50g organic bentonite, 50g urea-formaldehyde resin, 60g polyethylene wax, 160g EEA resin, 60g chlorinated polyethylene, 100g chlorinated polypropylene, 300g water-soluble amino resin , 100g alkyd resin, 80g propylene glycol, 400g deionized water, 120g OP-10, 100g OP-4.

[0062] The preparation method of above-mentioned coating protective material, comprises the following steps:

[0063] (1) Mix palm wax, microcrystalline wax and tea seed oil according to the proportion and heat to 85°C to obtain mixture I;

[0064] (2) Zinc stearate, triethanolamine, and Tween 80 were mixed according to the proportion and heated to 33°C to obtain mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com