High-resolution spectrograph based on etched diffraction grating

An etching diffraction grating, high-resolution technology, applied in the field of high-resolution spectrometers, can solve the problems of affecting resolution, output channel crosstalk, device resolution difficulties, etc., and achieve the effect of high resolution and low crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

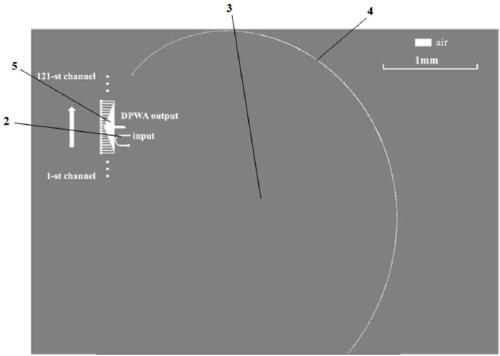

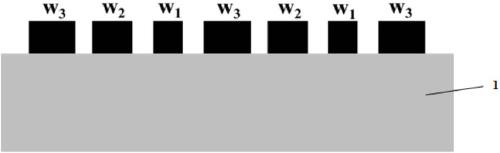

[0033] Such as figure 1 and figure 2 As shown, a high-resolution spectrometer based on an etched diffraction grating includes a substrate 1 , an input waveguide 2 , a free transmission region 3 , a reflective grating 4 and an output waveguide 5 . The input waveguide 2 , the free transmission area 3 , the reflective grating 4 and the output waveguide 5 are integrated on the substrate 1 . In this embodiment, the substrate 1 is an SOI substrate, and the thickness of the substrate is preferably 220nm. The input waveguide 2, reflection grating 3 and output waveguide 5 are prepared on the substrate by photolithography, and the rest of the area is the free transmission area 3.

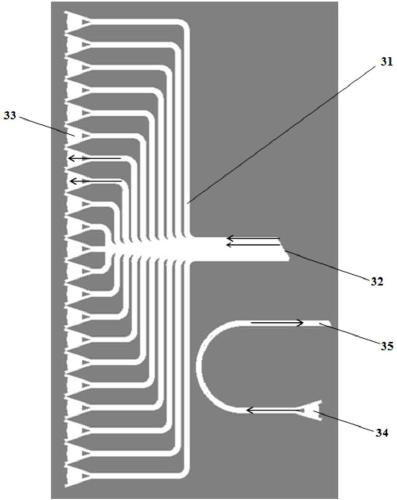

[0034] image 3 It is a partial enlarged view of the input waveguide and output waveguide of a preferred embodiment of the high-resolution spectrometer based on an etched diffraction grating in the present invention. The input and output adopt grating coupling. As shown in the figure, the output waveguide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com