Membrane electrode containing ordered catalytic layer as well as preparation method and application thereof

A technology for ordering catalytic layers and catalytic layers, applied in battery electrodes, circuits, fuel cells, etc., can solve problems such as poor performance, limited electronic resistance, etc., to reduce the amount of Pt used, reduce mass transfer polarization, and improve Effect of Catalyst Utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

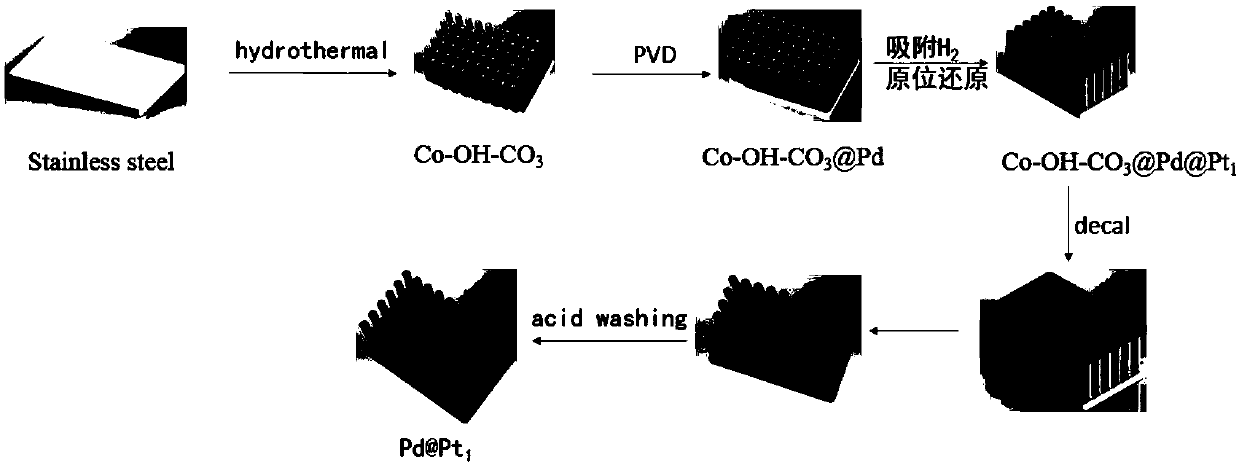

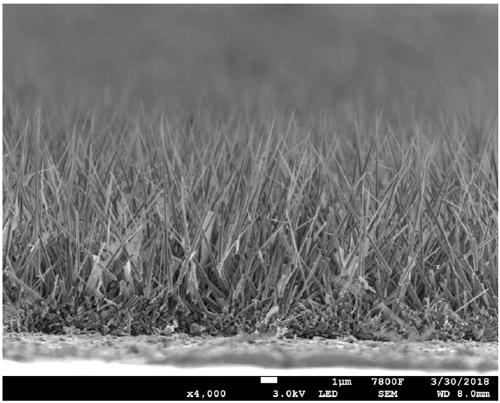

[0031] Step 1: Growth of Co-OH-CO on the surface of stainless steel sheet 3 nanorod arrays. Reaction temperature 120°C, reaction solution: reaction solution: 20mM Co(NO 3 ) 2 ·6H 2 O, 20mM NH 4 F, 40mM CO(NH 2 ) 2 , the array has a length of 5 μm and a diameter of 200-300 nm.

[0032] Step 2: PVD on Co-OH-CO 3 A layer of adsorbable H is deposited on the surface 2 metal Pd. The mode of physical vapor deposition adopts the mode of magnetron sputtering, and the ultimate vacuum pressure is 3.8×10 -3 Pa, working pressure 0.8Pa, power 120W, Ar gas flow 400sccm, time 15min.

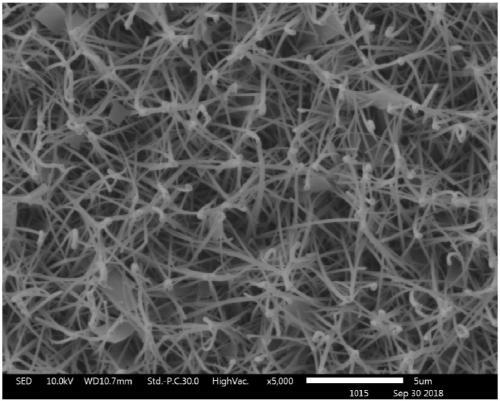

[0033] Step 3: H on the Pd surface 2 Preparation of Pt thin-layer catalysts by adsorption and reduction. will grow Co-OH-CO 3 The substrate of the @Pd nanorod array is placed obliquely in a beaker filled with deionized water, and the water containing H 2 Atmosphere, the concentration of the atmosphere is 100vol.%, the gas flow rate is 40sccm, and the ventilation time is 15min. The reduction proces...

Embodiment 2

[0038] Step 1: Growth of Co-OH-CO on the surface of stainless steel sheet 3 nanorod arrays. Reaction temperature 120°C, reaction solution: reaction solution: 20mM Co(NO 3 ) 2 ·6H 2 O, 20mM NH 4 F,40mMCO(NH 2 ) 2 , the array has a length of 5 μm and a diameter of 200-300 nm.

[0039] Step 2: PVD on Co-OH-CO 3 A layer of adsorbable H is deposited on the surface 2 metal Pd. The mode of physical vapor deposition adopts the mode of magnetron sputtering, and the ultimate vacuum pressure is 3.8×10 -3 Pa, working pressure 0.8Pa, power 120W, Ar gas flow 400sccm, time 15min.

[0040] Step 3: CO adsorption and reduction on Pd surface to prepare Pt thin-layer catalyst. will grow Co-OH-CO 3 The substrate of the @Pd nanorod array was placed obliquely in a beaker filled with deionized water, and an atmosphere containing CO was introduced into the water with an atmosphere concentration of 100vol.%, a gas flow rate of 40sccm, and an aeration time of 15min. The reduction process is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com