Battery pole piece photocatalytic degradation device and battery pole piece photocatalytic degradation equipment

A technology of battery pole piece and photocatalysis, which is applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of high degradation efficiency, environmental pollution, high cost, etc., and achieve improved circulation speed, simple process and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention will be further described below in conjunction with the drawings.

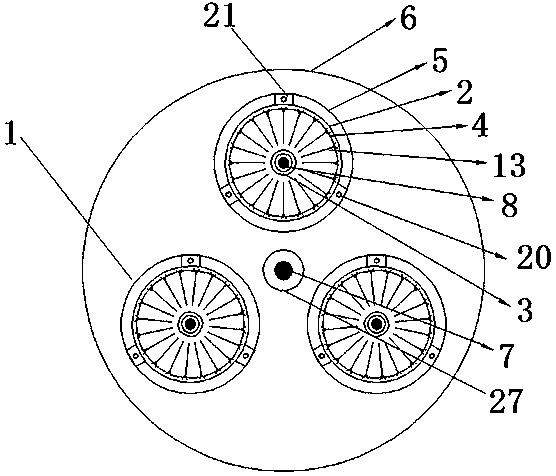

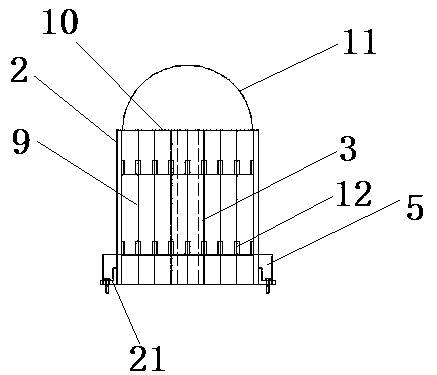

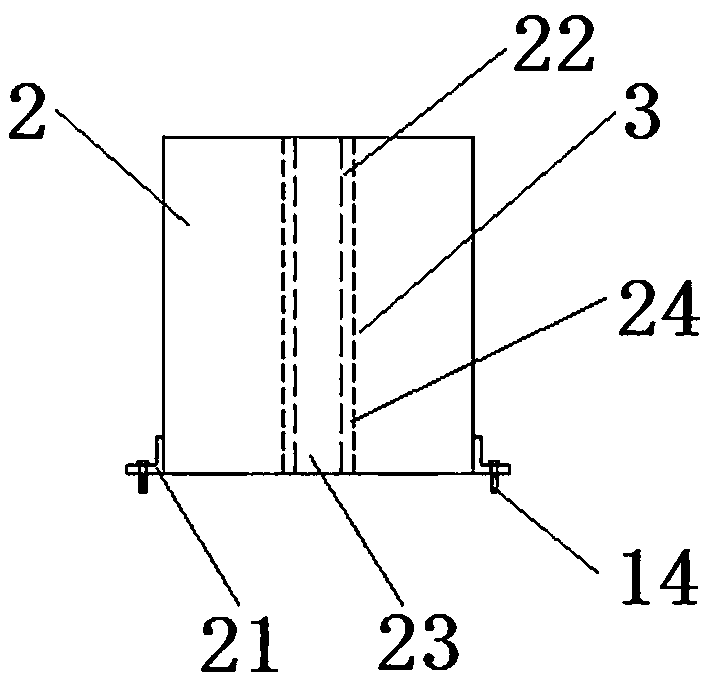

[0049] The specific embodiment of the photocatalytic degradation device for battery pole pieces provided by the present invention, such as figure 1 As shown, it includes a support table and three battery pole piece photocatalytic degradation devices 1 arranged on the support table. Specifically, the support table is a rotatable large tray 6, and the large tray 6 is connected with a driving mechanism for driving its rotation. , A sleeve 27 is provided at the center of the large tray 6, and a first cylindrical ultraviolet light source 7 is installed in the sleeve 27. In this embodiment, the sleeve 27 passes through the large tray 6 and is in clearance fit with the large tray 6, so that the large When the tray 6 rotates, the first cylindrical ultraviolet light source 7 does not move; the aforementioned three battery pole piece photocatalytic degradation devices 1 are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com