A flexible net dust collection device, dust removal system and dust removal method

A technology of dust collection device and dust removal system, which is applied in the direction of chemical instruments and methods, electrode cleaning, electrostatic effect separation, etc., can solve the problems of difficult site layout and renovation investment, large gap in ultra-low emission indicators, and excessive discharge concentration at the outlet, etc., to achieve Reduce investment in equipment emission reduction and transformation, reduce electrostatic adhesion, and reduce the effect of rapping intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

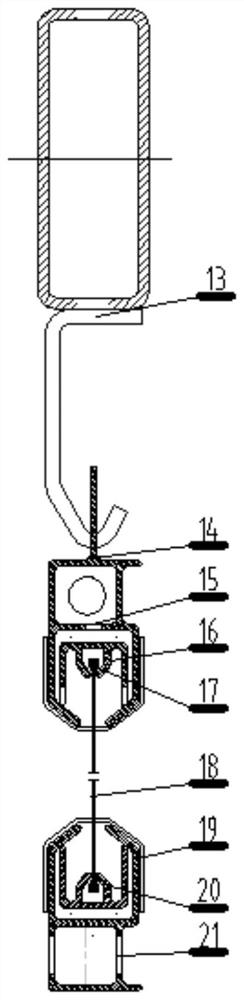

[0067] Such as figure 2 As shown, a single flexible net dust collector unit 2 is composed of an upper hanging box 14, a hollow rake-shaped jaw structure 16, a flexible net dust collector pole 18, a lower hanging box 19, and an end cover 23.

[0068] Such as Figure 4 and Figure 5 As shown, the upper hanging box 14 and the lower hanging box 19 are thin-walled profiles made of corrosion-resistant FRP through the pultrusion process. The resin and materials are adjusted according to the temperature of the treated smoke. The wall thickness is 3 mm and the length is 400 mm. ;The upper parts of the upper and lower hollow hanging boxes are square cavities, and the upper end of the upper hanging box has vertical ribs and two square holes. The bottom plates of the square cavities are arrayed at a distance of 30mm The water distribution hole 15 of the square chamber is provided with a water inlet pipe joint 24, and one end of the square chamber is closed by a sealing plate with a wa...

Embodiment 2

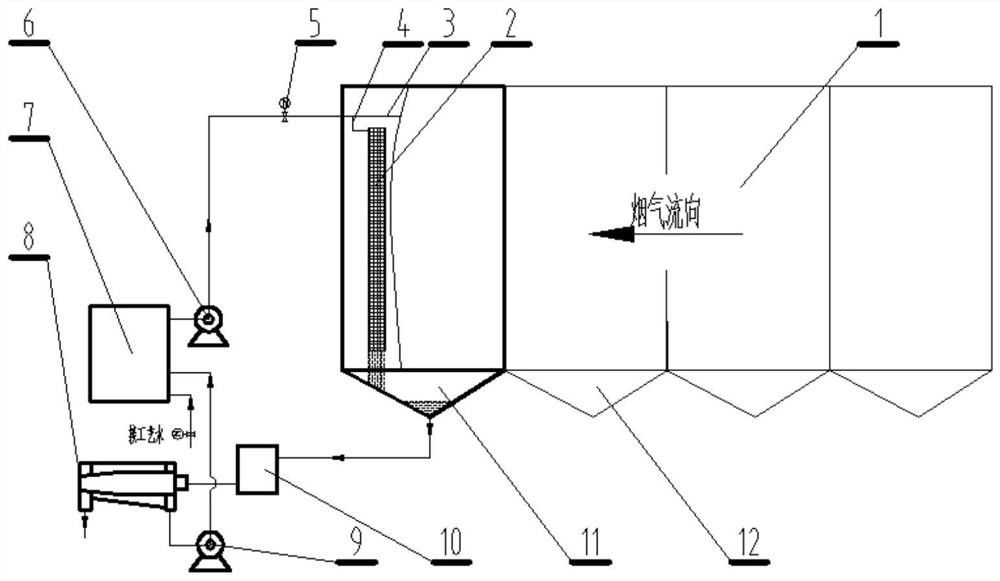

[0073] Such as figure 1 As shown, the working system of the flexible net dust collector consists of an electric dust collector 1, a flexible net dust collector 2, a main pipe 3, an electric valve 5, a circulating pump 9, a circulating water tank 7, a booster pump 6, a sewage tank 10, a horizontal screw It is composed of centrifuge 8 and other main equipment, and the overall connection relationship is as follows: one end of the electrostatic precipitator 1 is the flue gas inlet, and the opposite end is the flue gas outlet, and the bottom of the electrostatic precipitator 1 is a plurality of Connected ash hoppers, wherein the ash hopper at the lower part of the final electric field where the flexible net dust collection device 2 is located is pre-corrosion-treated to become a wet ash hopper 11, and the remaining ash hoppers remain in their original state and are still dry ash hoppers 12; the lower part of the wet ash hopper 11 is treated with sewage After the muddy water in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com