Device for preparing metal ingot through rapid solidification and lamination compounding

A metal ingot and stacking technology, applied in the field of metal ingots, can solve the problems of not being easy to prepare large-size ingots, low controllability of process parameters, high cost, etc., and achieve good controllability of process parameters and high composition Good consistency with the microstructure and high-efficiency preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

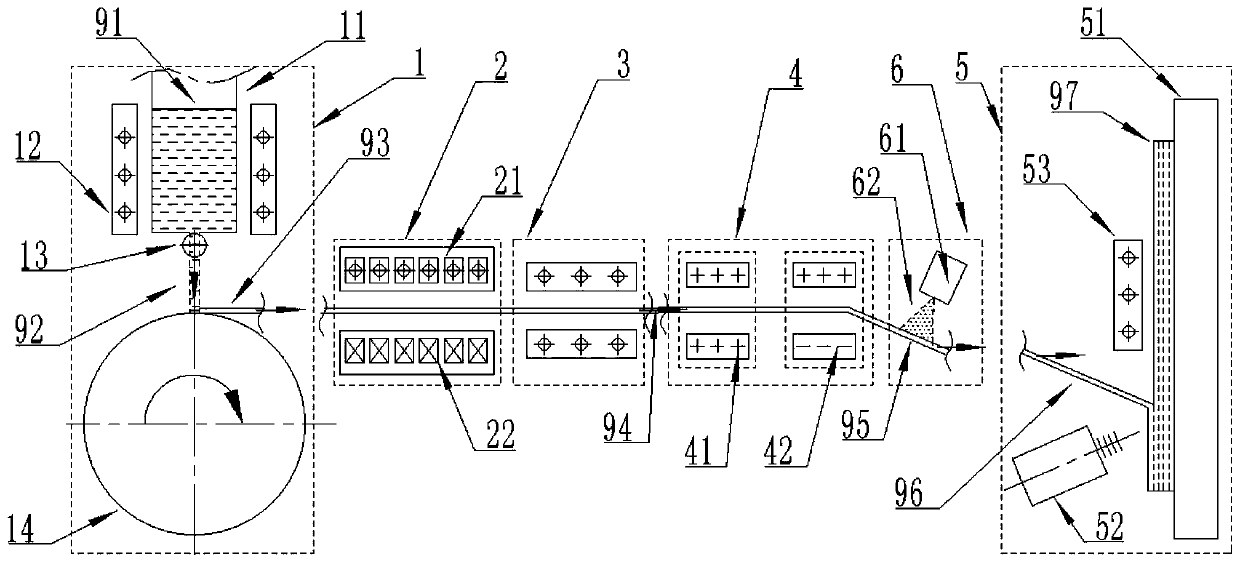

[0045] first embodiment, refer to figure 1 , an example of a rapid solidification laminated compound preparation metal ingot device designed by the present invention, including: a rapid quenching belt forming system 1, an acceleration system 2, a heating system 3, a deflection system 4, a laminated composite system 5 and a powder distribution system 6, specifically land:

[0046] The quenching belt forming system 1 is composed of a crucible 11 , a crucible heater 12 , a valve 13 and a quenching roller 14 . The bottom of the crucible 11 is provided with a slit, and the crucible heater 12 is induction heating, which is installed around the side wall of the crucible 11, and the crucible heater 12 is equipped with a temperature controller T1, so as to control the temperature of the molten metal 91. 10-500°C above the liquidus.

[0047] In some other embodiments, the slit is replaced by a row of fine holes, and the function of the fine holes is the same as that of the slit, whi...

no. 2 example

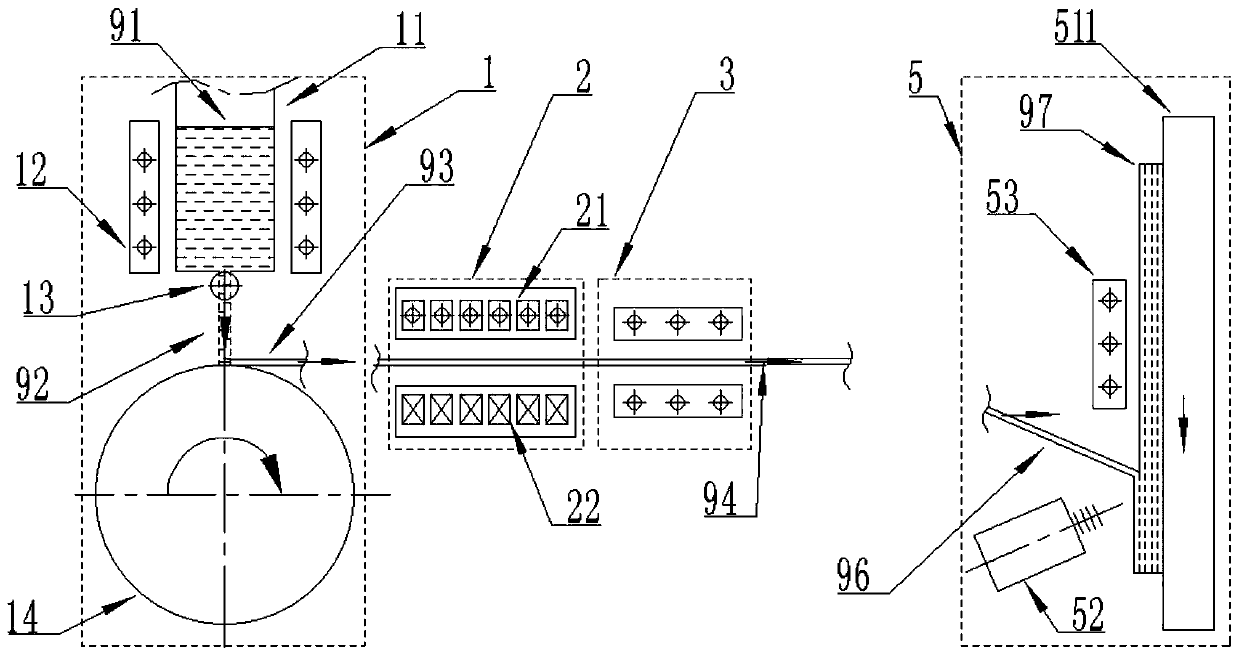

[0063] second embodiment , continue to refer to the first embodiment, and refer to figure 2 , the rapid solidification lamination composite preparation metal ingot device of this embodiment does not include the deflection system 4, that is, the straight-flying belt 94 after heating does not need deflection, but uses the self-gravity of the straight-flying belt 94 to achieve a certain deflection. The receiver 511 reciprocates up and down (refer to figure 2 Arrow in the middle plate type receiver 511), continuously accepts the straight-flying belt 94 to form the bonding belt 96. Make the straight-flying belt 94 move to the right and form the bonding point with the metal ingot 97 to become the bonding tape 96, the receiver 51 moves downwards and pulls the bonding tape 96 to shift downwards, while the bonding point moves upwards, and the bonding tape 96 Combine with the metal ingot 97 successively from bottom to top, so that the metal ingot 97 is thickened by one layer, and a...

no. 3 example

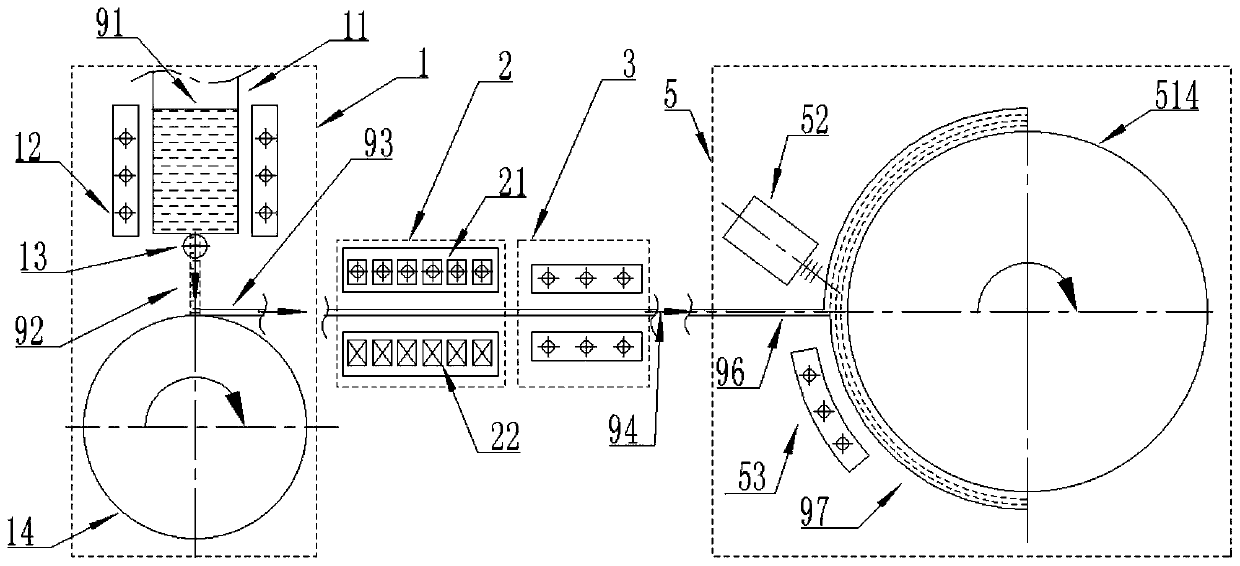

[0064] third embodiment , continue to refer to the second embodiment, and refer to image 3, the rapid solidification lamination compound preparation metal ingot device in this embodiment does not include the deflection yoke 4 , and the receiver 51 adopts a cylindrical receiver 514 . The continuous rotation of the cylindrical receiver 514 produces a deflection force, and the adhesive tape 96 is combined with the metal ingot 97 under the action of the heater 53 and the compactor 52. The continuous rotation of the cylindrical receiver 514 realizes that the adhesive tape 96 is in the receiver The continuous layering of the surface, likewise, the receiver is able to move to the right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com