Automatic clamping device of protection cover for horizontal bunker car carrier roller bearing pedestal for mine

A bearing seat and horizontal technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of taking up more man-hours, not completely uniform in size, and more stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

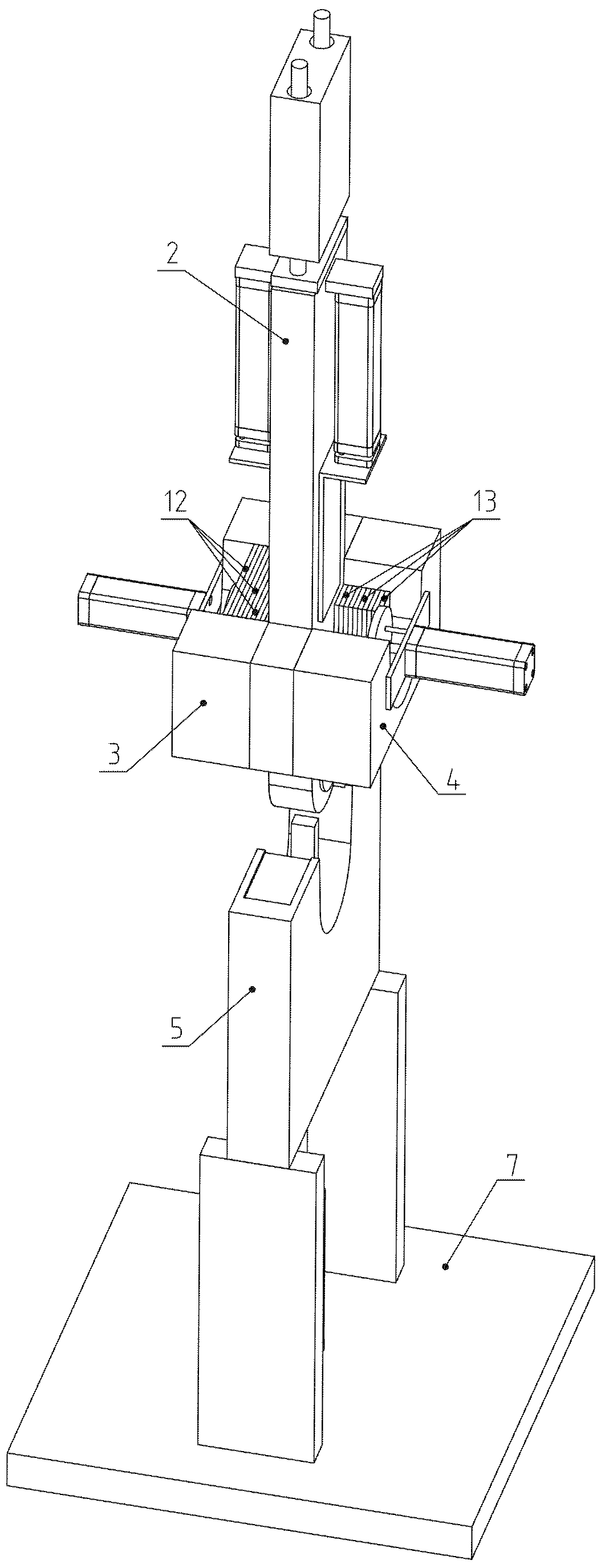

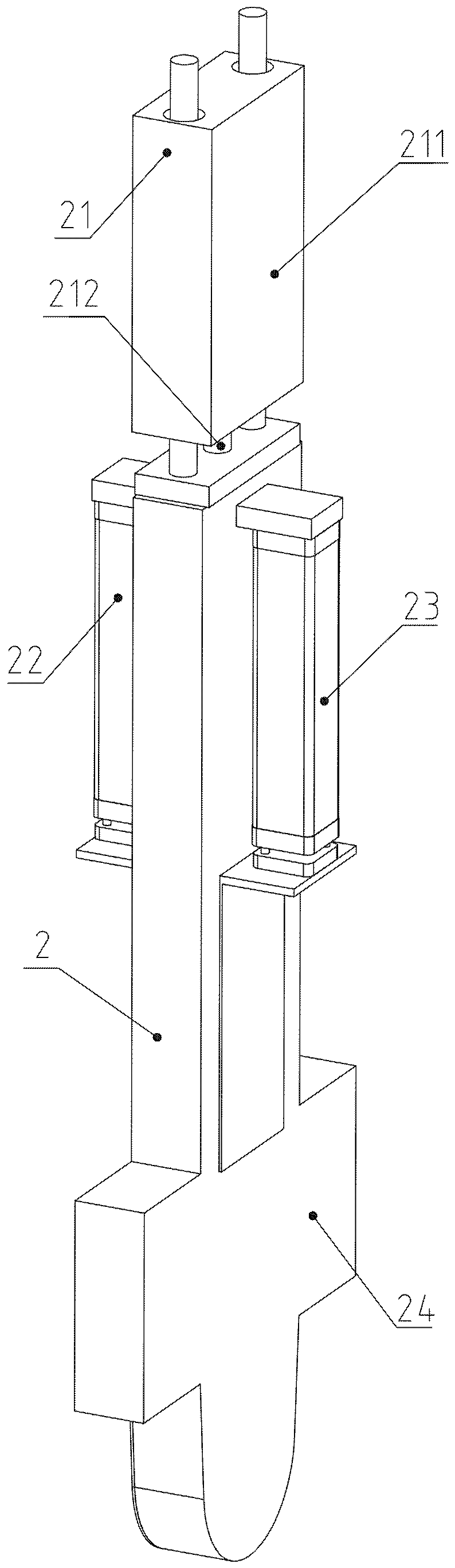

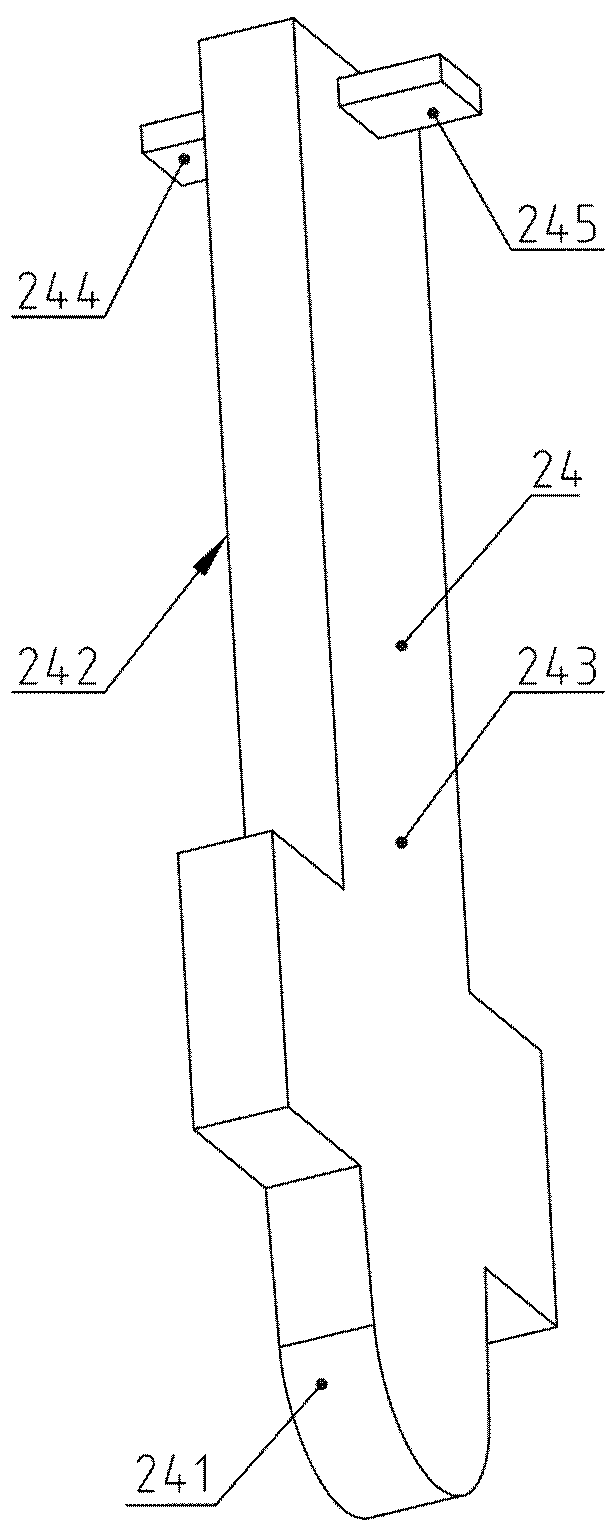

[0062] Example: see Figure 1 to Figure 18 .

[0063] An automatic clamping device for a protective cover for a roller bearing seat of a horizontal warehouse car used in mines, including an upper mold assembly 2, a rear feeder 3, a front feeder 4, a lower mold 5, a channeling prevention assembly 6 and a frame 7;

[0064] The lower die 5 is in the shape of a cuboid, and the lower die 5 is fixedly connected to the frame 7. The upper surface of the lower die 5 is provided with a rectangular arc-shaped sheet material trough 51, and the middle part of the arc-shaped sheet material trough 51 is provided with a lower die. U-shaped groove 52; the U-shaped groove 52 of the lower mold extends along the front-to-back direction, the U-shaped groove 52 of the lower mold opens upward, and the U-shaped groove 52 of the lower mold is transparent from front to back; the groove bottom of the U-shaped groove 52 of the lower mold is provided with The square hole 53 of the lower mold, the square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com