Automatic operation lithographic offset press

An offset printing machine and offset printing technology, which is applied in the direction of flat-bed flat printing machine, printing machine, printing, etc., can solve the problems of large production environment and air pollution, unfavorable environmental protection production, and large workshop area, so as to shorten the length of equipment and improve The effect of register degree and improvement of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

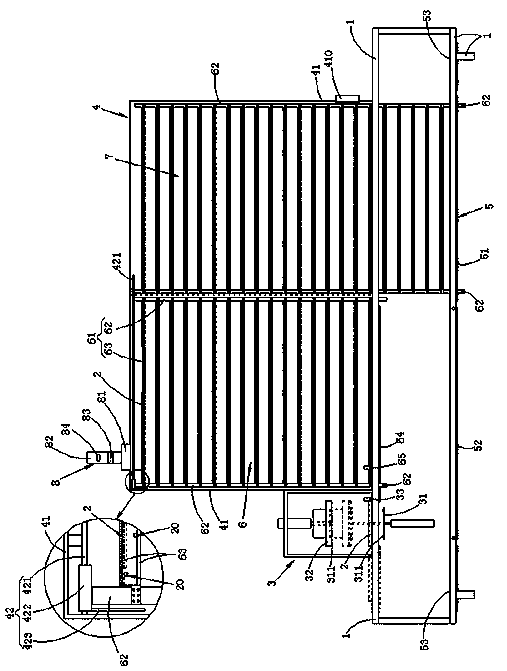

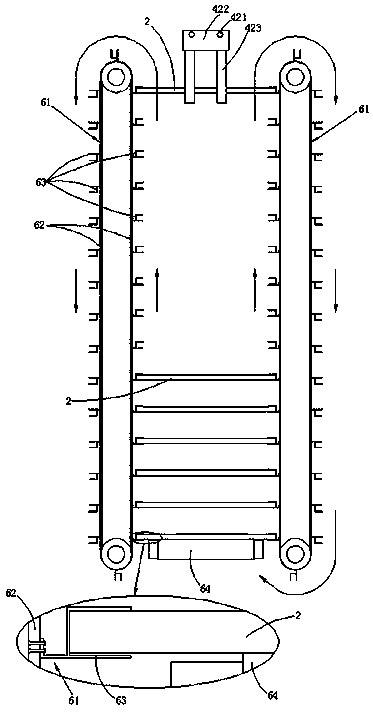

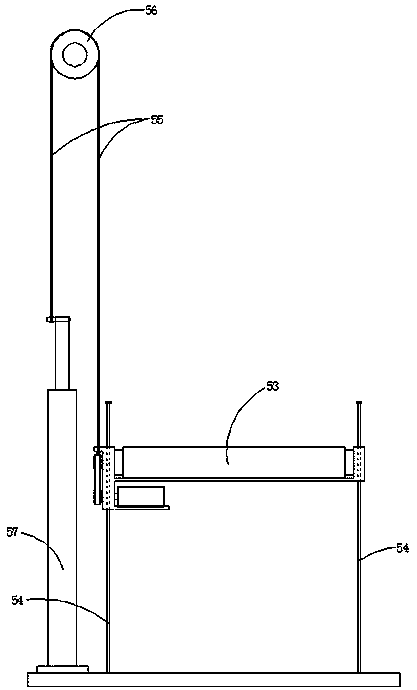

[0018] refer to Figure 1 to Figure 3 , the lithographic offset printing machine of the automatic operation of the present embodiment comprises a main frame 1 and an offset printing device 3 , a drying device 4 , and a material receiving device 5 which are sequentially passed by a tray 2 assembled on the main frame 1 , and the tray 2 is fixedly installed with flat substrate.

[0019] Continue to refer to figure 1 , the above-mentioned offset printing device 3 is used to perform positioning offset printing on the planar substrates in the trays 2 that pass sequentially. The above-mentioned offset printing device 3 includes a lifting table 31, an offset printing plate 32, and a stop trigger 33. When the tray 2 enters the offset printing device 3 to a designated position, the pulling stop trigger is triggered to stop the progress of the pallet 2. The tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com