Steel slag aggregate type semi-flexible paving material and preparation method thereof

A pavement material, semi-flexible technology, applied in the field of pavement construction materials, can solve the problems of high preparation cost and difficulty in wide-scale promotion, and achieve the effect of less free asphalt, good compatibility and complete voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

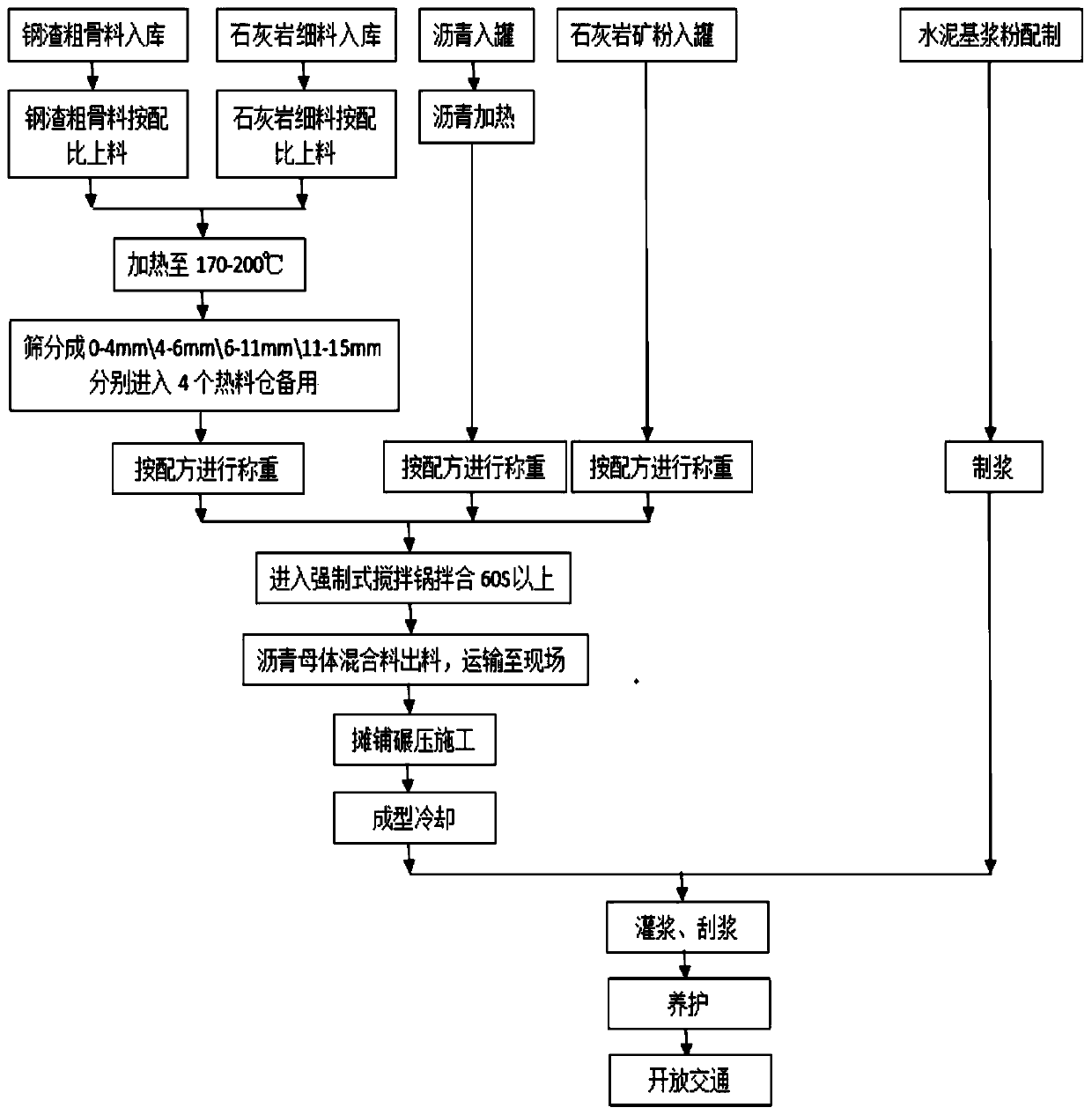

[0027] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

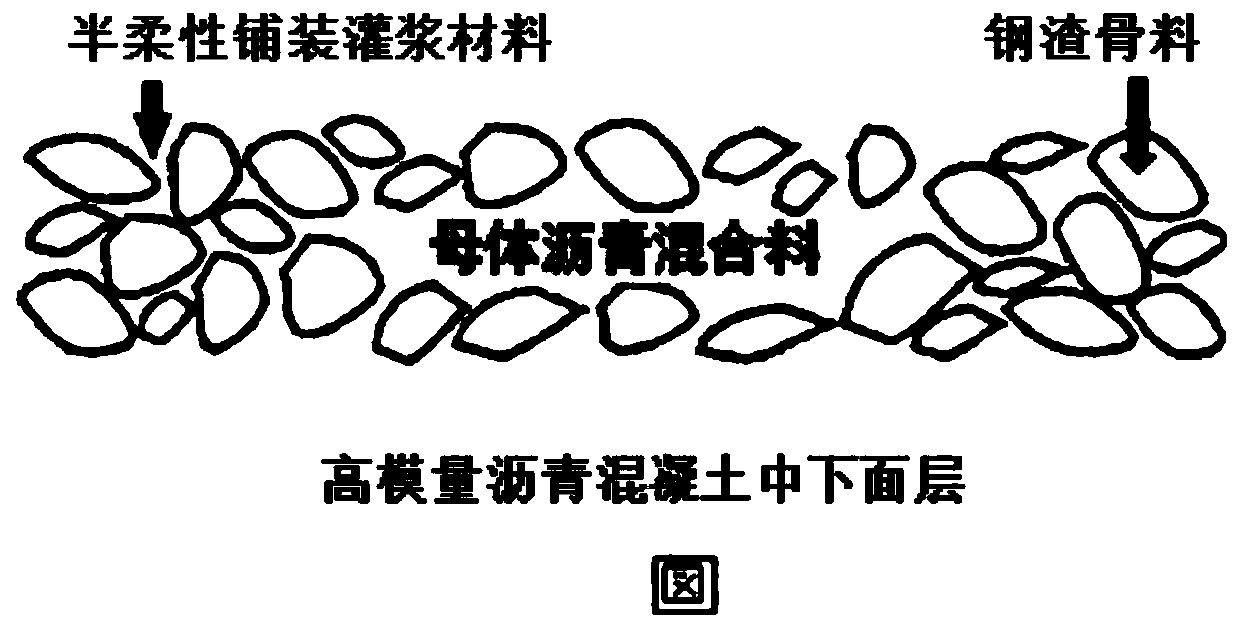

[0028] In specific embodiment 1, a steel slag aggregate type semi-flexible paving material includes two parts: a large-void steel slag aggregate type asphalt matrix material and a semi-flexible paving grouting material;

[0029] Among them, the large-void steel slag aggregate type asphalt matrix material includes the following materials according to the weight ratio: 4.0%-4.5% SBS modified asphalt, 75%-85%% 5-15mm coarse steel slag aggregate, 8%-12 % Limestone fine material, 3%-5% limestone powder, 0.3%-0.6% high viscosity modifier;

[0030] The semi-flexible paving grouting material includes 100 parts by weight of dry powder grouting material and 27-35 parts of water. The dry powder grouting material includes 52.5 fast hardenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com