Reinforced polyamide 66 composition and preparation method thereof

A technology of polyamide and composition, applied in the field of reinforced polyamide 66 composition and its preparation, can solve the problems of poor dimensional stability, low impact strength and high dielectric constant, achieve low dielectric constant, improve impact performance, improve Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

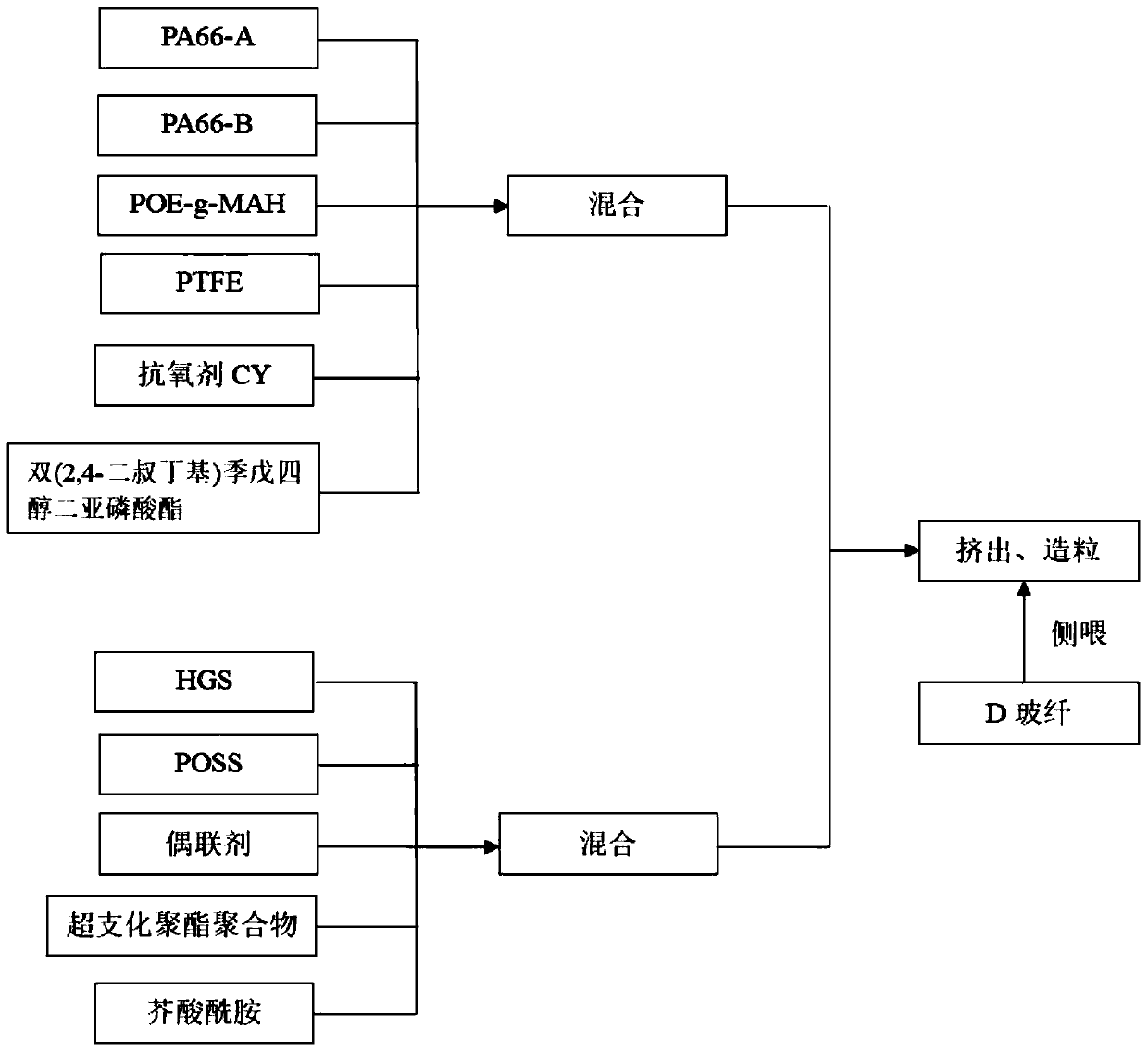

Method used

Image

Examples

Embodiment 1

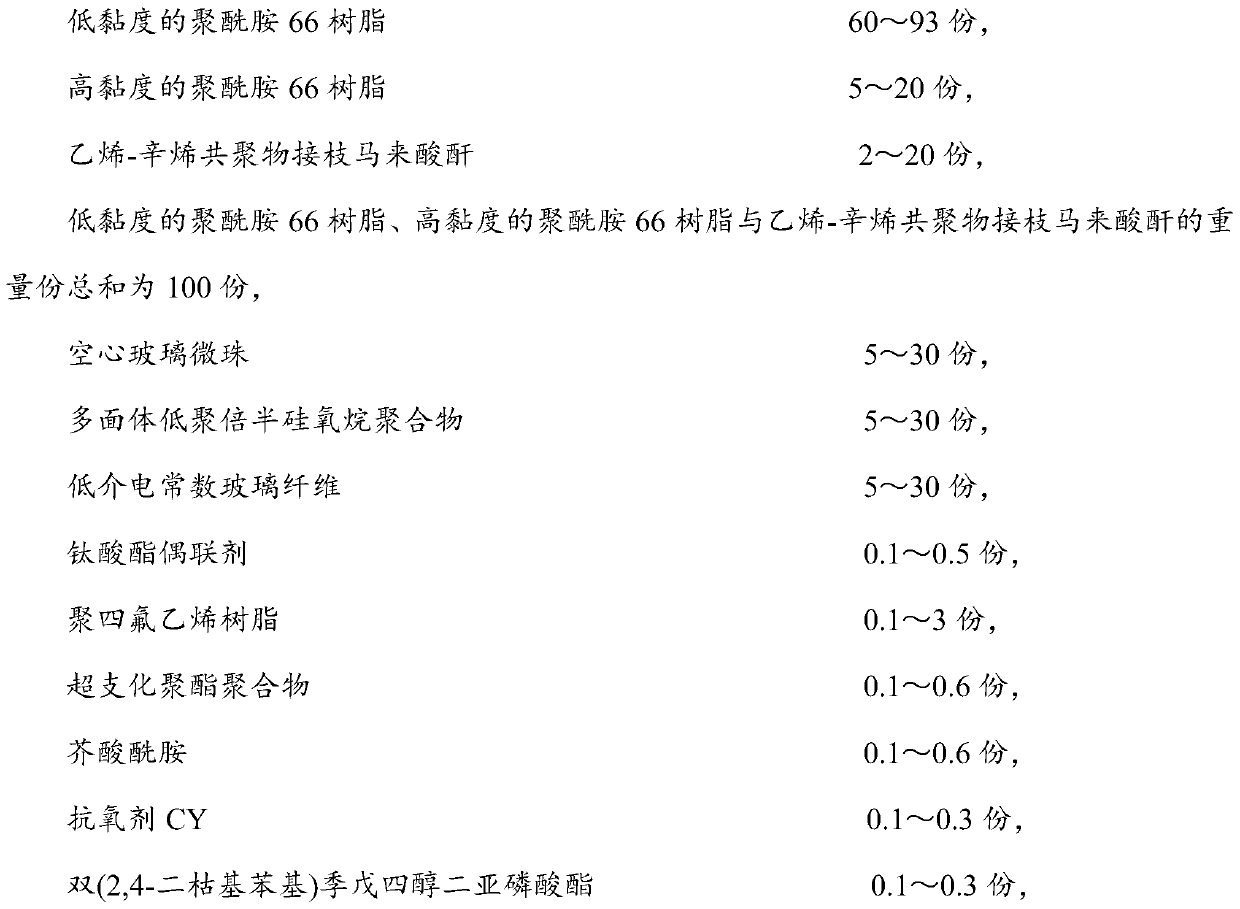

[0096] This embodiment provides a reinforced polyamide 66 composition prepared from the following raw materials in parts by weight:

[0097] 60 parts of low-viscosity polyamide 66 resin,

[0098] High viscosity polyamide 66 resin 20 parts,

[0099] 20 parts of ethylene-octene copolymer grafted maleic anhydride,

[0100] The sum of the parts by weight of low-viscosity polyamide 66 resin, high-viscosity polyamide 66 resin and ethylene-octene copolymer grafted maleic anhydride is 100 parts,

[0101]

[0102] The preparation method of above-mentioned reinforced polyamide 66 composition, comprises the following steps:

[0103] (1) Place the low-viscosity polyamide 66 resin and the high-viscosity polyamide 66 resin at a temperature of 90° C. for 8 hours to dry, then cool, and the cooled low-viscosity polyamide 66 resin and high-viscosity polyamide 66 resin Polyamide 66 resin and the ethylene-octene copolymer graft maleic anhydride, polytetrafluoroethylene resin, antioxidant CY...

Embodiment 2

[0108] This embodiment provides a reinforced polyamide 66 composition prepared from the following raw materials in parts by weight:

[0109] Low viscosity polyamide 66 resin 93 parts,

[0110] High viscosity polyamide 66 resin 5 parts,

[0111] 2 parts of ethylene-octene copolymer grafted maleic anhydride,

[0112] The sum of the parts by weight of low-viscosity polyamide 66 resin, high-viscosity polyamide 66 resin and ethylene-octene copolymer grafted maleic anhydride is 100 parts,

[0113]

[0114] The preparation method of above-mentioned reinforced polyamide 66 composition, comprises the following steps:

[0115] (1) Place the low-viscosity polyamide 66 resin and the high-viscosity polyamide 66 resin at a temperature of 120° C. for 4 hours to dry, then cool, and the cooled low-viscosity polyamide 66 resin and high-viscosity polyamide 66 Polyamide 66 resin and the ethylene-octene copolymer graft maleic anhydride, polytetrafluoroethylene resin, antioxidant CY, bis(2,4-...

Embodiment 3

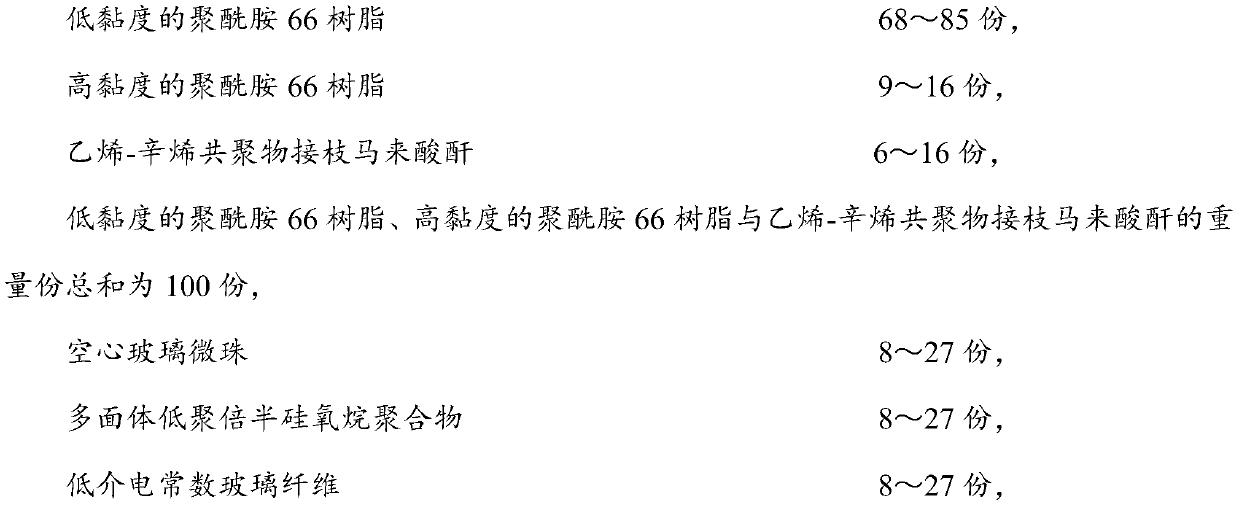

[0120] This embodiment provides a reinforced polyamide 66 composition prepared from the following raw materials in parts by weight:

[0121] 68 parts of low-viscosity polyamide 66 resin,

[0122] High viscosity polyamide 66 resin 16 parts,

[0123] 16 parts of ethylene-octene copolymer grafted maleic anhydride,

[0124] The sum of the parts by weight of low-viscosity polyamide 66 resin, high-viscosity polyamide 66 resin and ethylene-octene copolymer grafted maleic anhydride is 100 parts,

[0125]

[0126] The preparation method of above-mentioned reinforced polyamide 66 composition, comprises the following steps:

[0127] (1) Place the low-viscosity polyamide 66 resin and the high-viscosity polyamide 66 resin at a temperature of 100° C. for 6 hours, and then cool, and the cooled low-viscosity polyamide 66 resin and high-viscosity polyamide 66 resin Polyamide 66 resin and the ethylene-octene copolymer graft maleic anhydride, polytetrafluoroethylene resin, antioxidant CY, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap