Preparation method and preparation equipment of multifunctional putty powder

A putty powder, multi-functional technology, applied in the field of putty powder, can solve the problems of reducing the overall aesthetics of the wall surface and service life, weak bonding ability and waterproof performance, cracking of putty powder, etc., to improve waterproof effect and flow performance , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

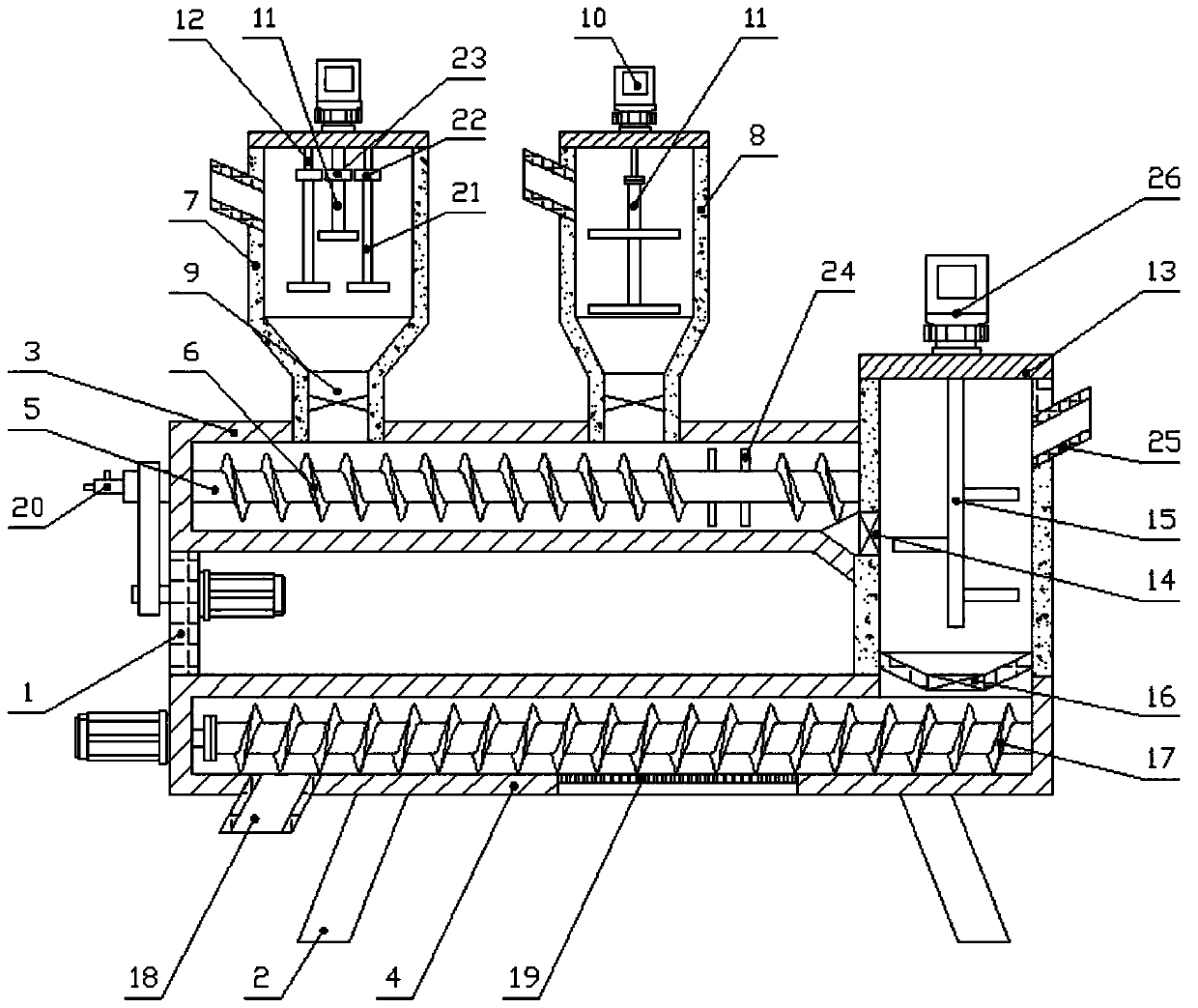

[0029]Embodiment 1: Utilize above-mentioned a kind of method for the preparation of multifunctional putty powder preparation equipment, its preparation raw material is made up of base material, cement, waterproof raw material, masterbatch, and above-mentioned each component is respectively by weight part: base material 550 parts, 330 parts of cement, 20 parts of waterproof raw materials, 40 parts of masterbatch; said masterbatch includes redispersible latex powder, cellulose, starch ether, hydrophobic agent, water reducing agent, rosin powder, calcium formate; masterbatch each The components in parts by weight are: 20 parts of redispersible latex powder, 1 part of cellulose, 0.3 parts of starch ether, 1.5 parts of hydrophobic agent, 0.2 parts of water reducing agent, 3 parts of rosin powder, and 7 parts of calcium formate; The preparation process includes the following steps:

[0030] 1) Put the crushed base material into the front mixing tank 7 for stirring, and at the same t...

Embodiment 2

[0036] Embodiment 2: The preparation process is the same as in Example 1, but the components of the raw materials are in parts by weight: 650 parts of base material, 430 parts of cement, 50 parts of waterproof raw materials, and 60 parts of masterbatch; each group of masterbatch Parts by weight are: 30 parts of redispersible latex powder, 2.5 parts of cellulose, 0.8 part of starch ether, 3 parts of hydrophobic agent, 0.8 part of water reducing agent, 7 parts of rosin powder, and 12 parts of calcium formate.

Embodiment 3

[0037] Embodiment 3: The preparation process is the same as in Example 1, but the components of the raw materials are in parts by weight: 600 parts of base material, 400 parts of cement, 45 parts of waterproof raw materials, and 45 parts of masterbatch; each group of masterbatch Parts by weight are: 25 parts of redispersible latex powder, 2 parts of cellulose; 0.5 part of starch ether, 2 parts of hydrophobic agent, 0.5 part of water reducing agent, 5 parts of rosin powder, and 10 parts of calcium formate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com