Method for preparing high-purity galactooligosaccharide by beta-galactosidase

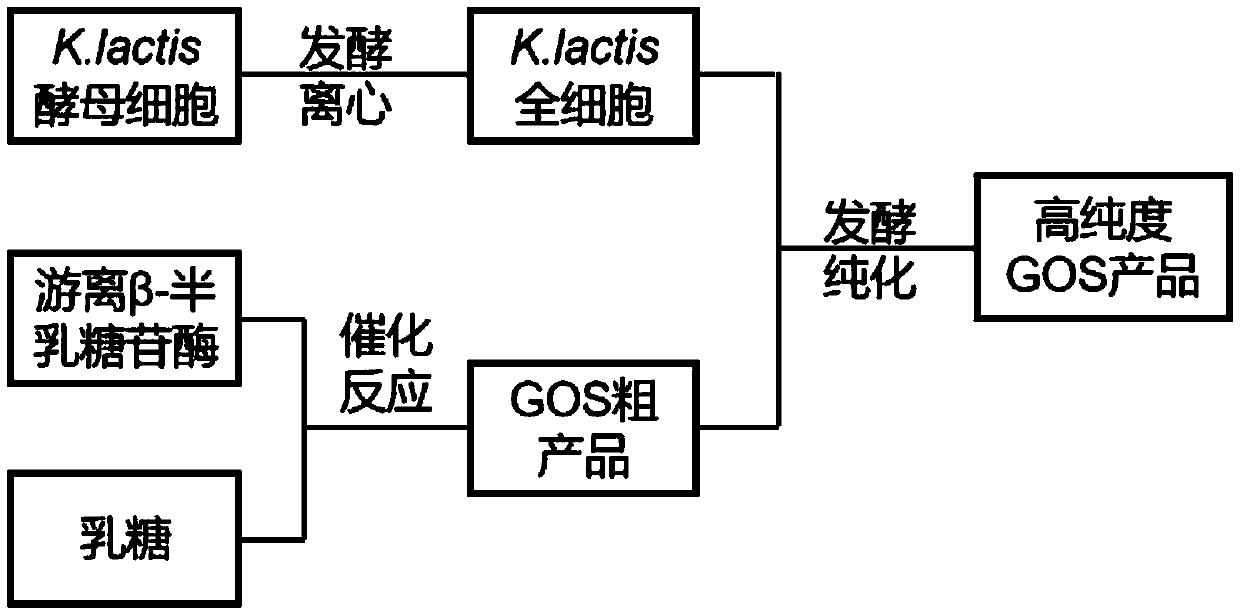

A technology of galacto-oligosaccharide and galactosidase, which is applied in microorganism-based methods, biochemical equipment and methods, fungi, etc., can solve the problems of difficulty in industrialized production, expensive enzyme preparations, and low recycling rate. , to achieve mild and pollution-free fermentation conditions, reduce the consumption of preparation links, and achieve mild fermentation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Free β-galactosidase catalyzes lactose to prepare crude galactooligosaccharides by transglycosidation reaction:

[0027] Prepare 400g / L lactose solution using 50mM phosphate buffer solution with pH = 8, take 20mL lactose solution and put it in a 50mL jar, dilute it 1000 times and measure the enzyme of free β-galactosidase enzyme solution by enzyme activity detection method The activity is 36U / mL, add free β-galactosidase enzyme solution according to the ratio of 30U / g lactose, react at 37°C, 160rpm constant temperature shaking water bath for 2h, after the reaction is completed, use boiling water to inactivate for 10min, and obtain the crude product of GOS . The crude GOS product was diluted with pure water to an appropriate multiple, filtered with a 0.45 μm filter membrane, and the content of each component in the product was detected by high-performance liquid chromatography according to HPLC detection conditions, and the yield of GOS was measured to be 22.78%.

...

Embodiment 2

[0036] (1) Free β-galactosidase catalyzes lactose to prepare crude galactooligosaccharides by transglycosidation reaction:

[0037]Prepare 400g / L lactose solution using 50mM phosphate buffer solution with pH = 8, take 20mL lactose solution and put it in a 50mL jar, dilute it 1000 times and measure the enzyme of free β-galactosidase enzyme solution by enzyme activity detection method The activity is 36U / mL, add free β-galactosidase enzyme solution according to the ratio of 25U / g lactose, react at 37°C, 160rpm constant temperature shaking water bath for 2h, after the reaction is completed, use boiling water to inactivate for 10min, and obtain the crude product of GOS . The crude GOS product was diluted with pure water to an appropriate multiple, filtered through a filter membrane of 0.45 μm, and the content of each component in the product was detected by high-performance liquid chromatography according to HPLC detection conditions, and the yield of GOS was measured to be 21.04%...

Embodiment 3

[0044] (1) Free β-galactosidase catalyzes lactose to prepare crude galactooligosaccharides by transglycosidation reaction:

[0045] Prepare 500g / L lactose solution using 50mM phosphate buffer solution with pH=9, take 20mL lactose solution and place it in a 50mL jar, dilute it 1000 times and measure the enzyme activity of free β-galactosidase enzyme solution by enzyme activity detection method The activity is 36U / mL, add free β-galactosidase enzyme solution according to the ratio of 1U / g lactose, react in a constant temperature shaking water bath at 25°C and 160rpm for 2h, and inactivate with boiling water for 10min after the reaction is completed to obtain the crude product of GOS . The crude GOS product was diluted with pure water to an appropriate multiple, filtered through a filter membrane of 0.45 μm, and the content of each component in the product was detected by high-performance liquid chromatography according to HPLC detection conditions, and the yield of GOS was measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com