Thermal compounding high-speed stacking machine

A thermal lamination and lamination machine technology, applied in battery assembly, sustainable manufacturing/processing, climate sustainability, etc., can solve the potential safety hazards of cells, lamination efficiency, cell volume can not keep up with demand, extreme It can improve the quality of the laminations, prevent the laminations from loosening, and improve the quality of the cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

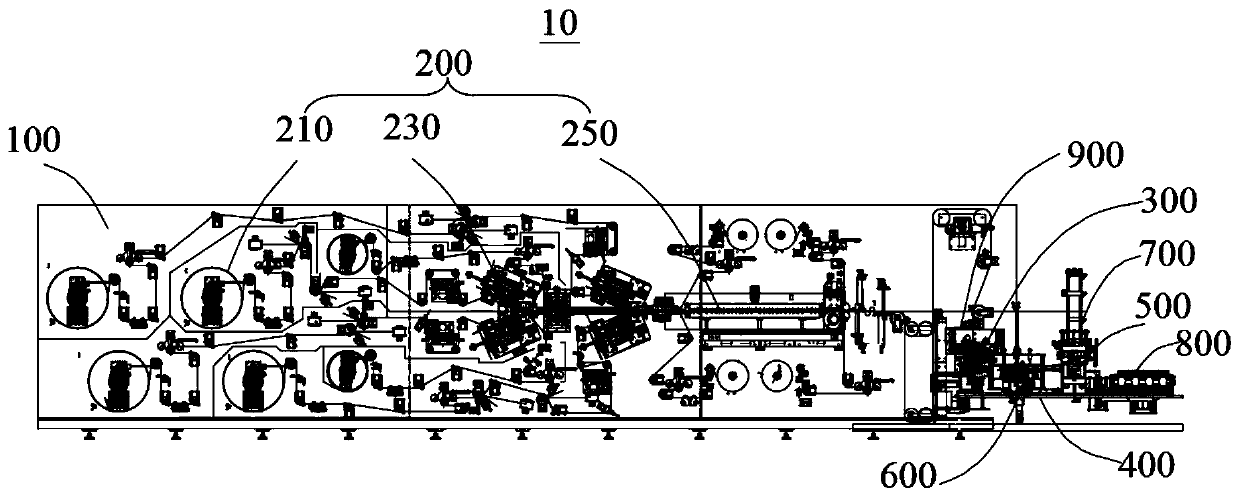

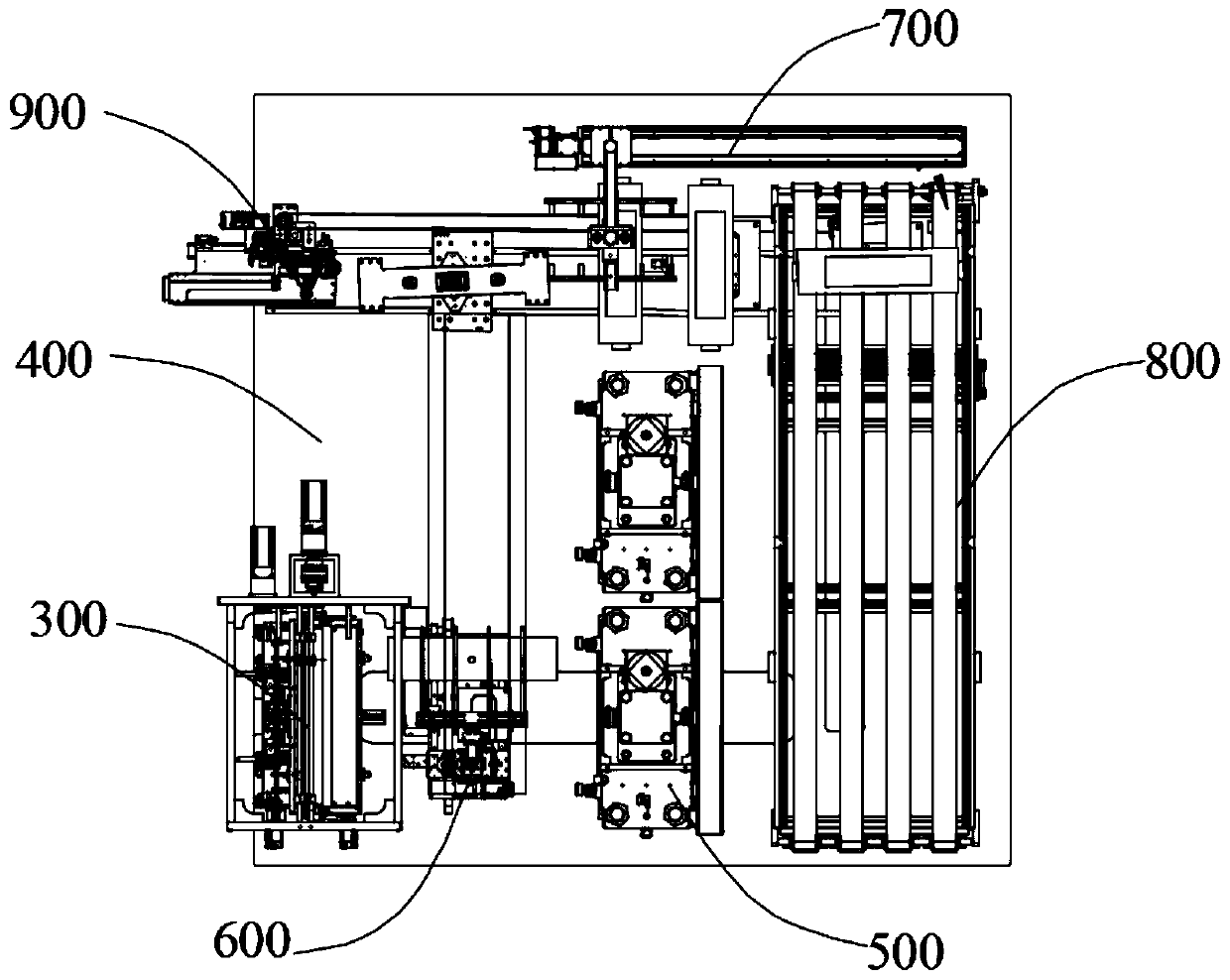

[0035]see in conjunction Figure 1 to Figure 3 , the present invention provides a thermal compound high-speed stacking machine 10, which has high stacking efficiency and high-quality battery cells, and can effectively avoid the slipping of the composite pole piece.

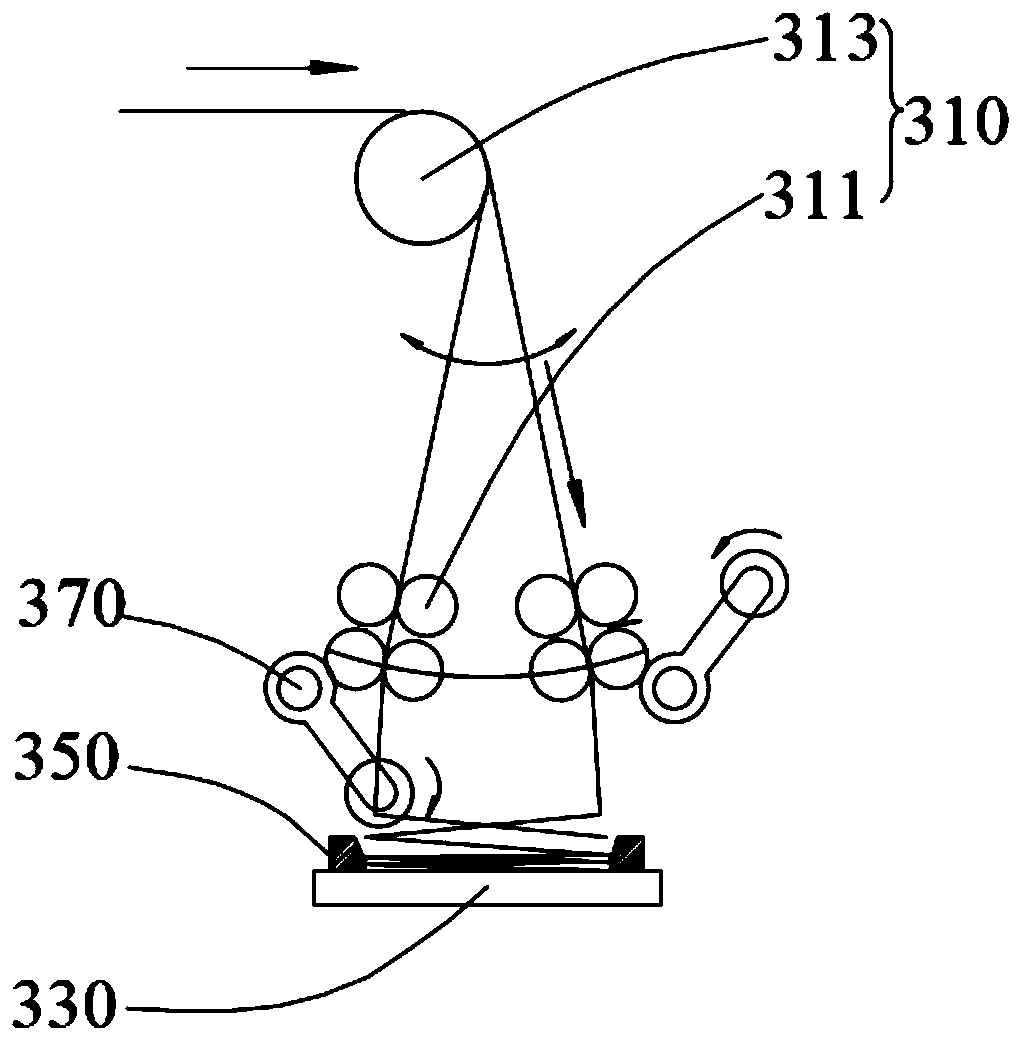

[0036] The thermal compound high-speed laminating machine 10 provided in this embodiment includes a supporting wallboard 100, a film making device 200, a laminating device 300, a frame 400, a hot pressing table 500, a reclaiming manipulator 600, an unloading manipulator 700 and a conveying assembly 800, the sheet making device 200 and the sheet stacking device 300 are arranged at intervals on the supporting wallboard 100, the sheet making device 200 is used to form composite pole pieces, the sheet stacking device 300 includes a swing roller assembly 310 and a folding stacking platform 330, the swing roller assembly 310 is arranged above the folding table 330, and is used for folding and stacking composite pole pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com