Application of cationized polysaccharide polymer in improving foam performance of surfactants

A technology of cationic polymers and polysaccharide polymers, which is applied in the field of daily chemical industry, can solve the problems of insignificant improvement of foam performance of polymers, incompatibility of polymers and surfactant systems, etc., and achieve foaming performance and foam stabilizing performance Improve, not easy to dissipate, improve the effect of fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

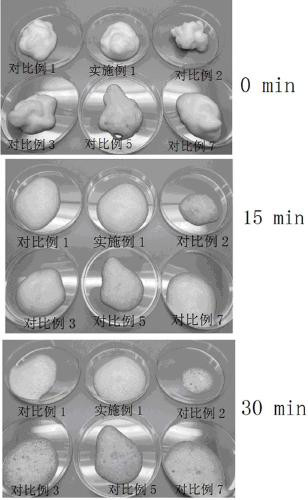

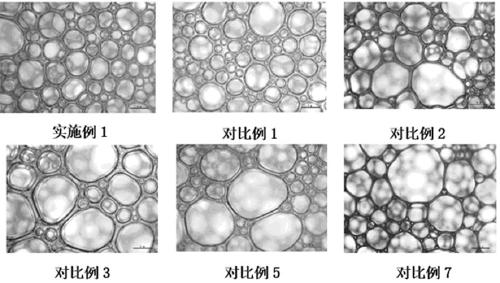

Examples

Embodiment 1

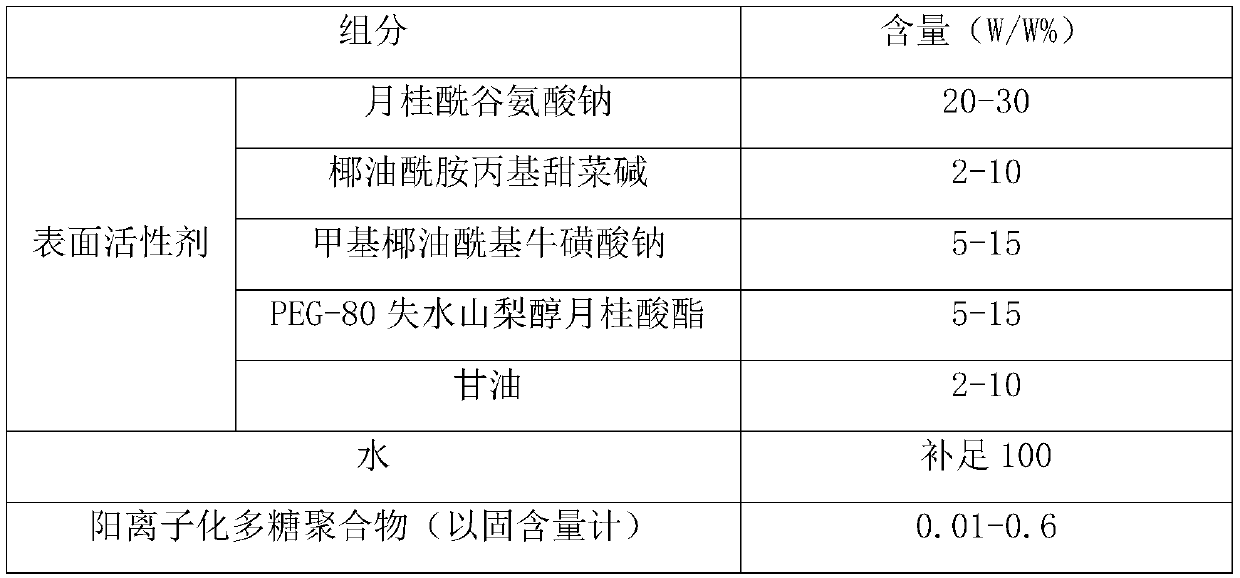

[0031] Formulate the amino acid foam system according to the formula in Table 2 below, wherein the cationic sodium hyaluronate used is prepared from sodium hyaluronate and cationic polymer according to the method in patent 201610408684.8, the molecular weight of sodium hyaluronate is 3000-10000Da, and the cationic polymer It is polyquaternium-10 (PQ-10) of DOW company, the mass ratio of sodium hyaluronate to PQ-10 is 1:4~1:5, the viscosity of the final product is 500-1000rpm, and the active matter content is 15% , pH 4.8-5.5.

[0032] Table 2

[0033]

[0034] The preparation method is:

[0035] Put water, glycerin, sodium lauroyl glutamate, PEG-80 sorbitan laurate, and cocamidopropyl betaine into a beaker, stir and heat to 60-65°C, add methyl cocoyl oxalate Sodium sulfonate, stir to dissolve until completely homogeneous. Then lower it to 40-45°C, add cationic sodium hyaluronate, stir evenly, and then lower it to room temperature to obtain an amino acid foam system.

Embodiment 2

[0037] The amino acid foam system was prepared according to the formula and method of Example 1, except that the content of cationized sodium hyaluronate was 0.1 wt%.

Embodiment 3

[0039] The amino acid foam system was prepared according to the formula and method of Example 1, except that the content of cationized sodium hyaluronate was 4 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com