Environment-friendly special furnace for melting EPS lost foam

An environmentally friendly, lost foam technology, used in furnaces, molds, cores, etc., can solve problems such as polluted atmosphere and uneven temperature field of melting furnaces, and achieve the effect of enhancing safety performance and avoiding heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

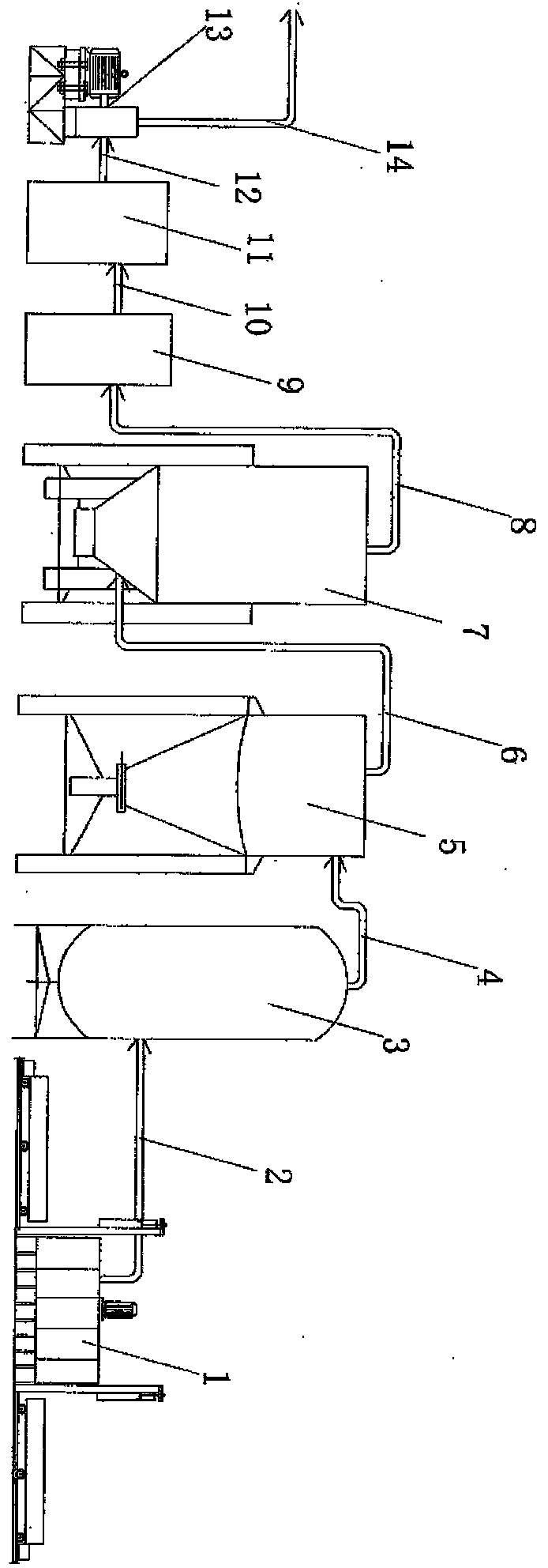

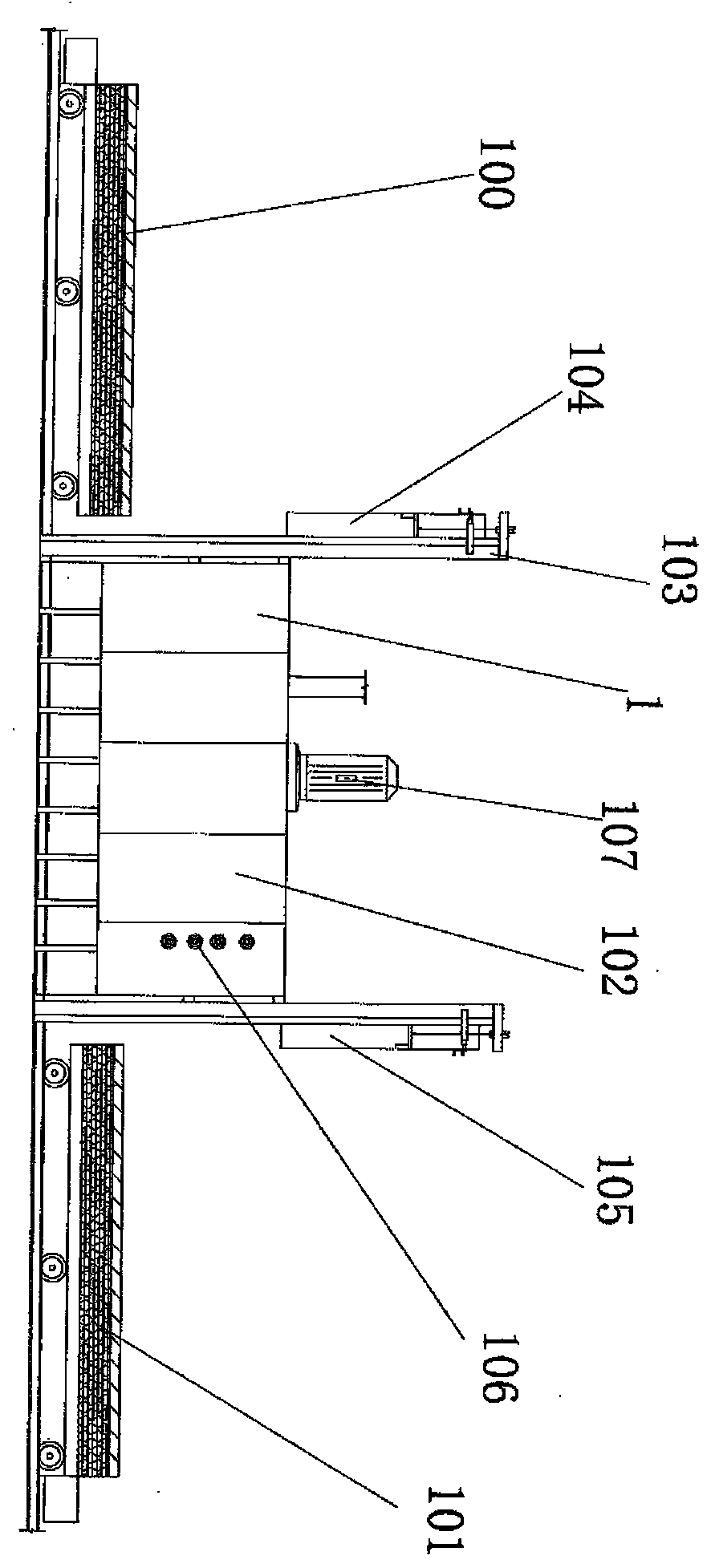

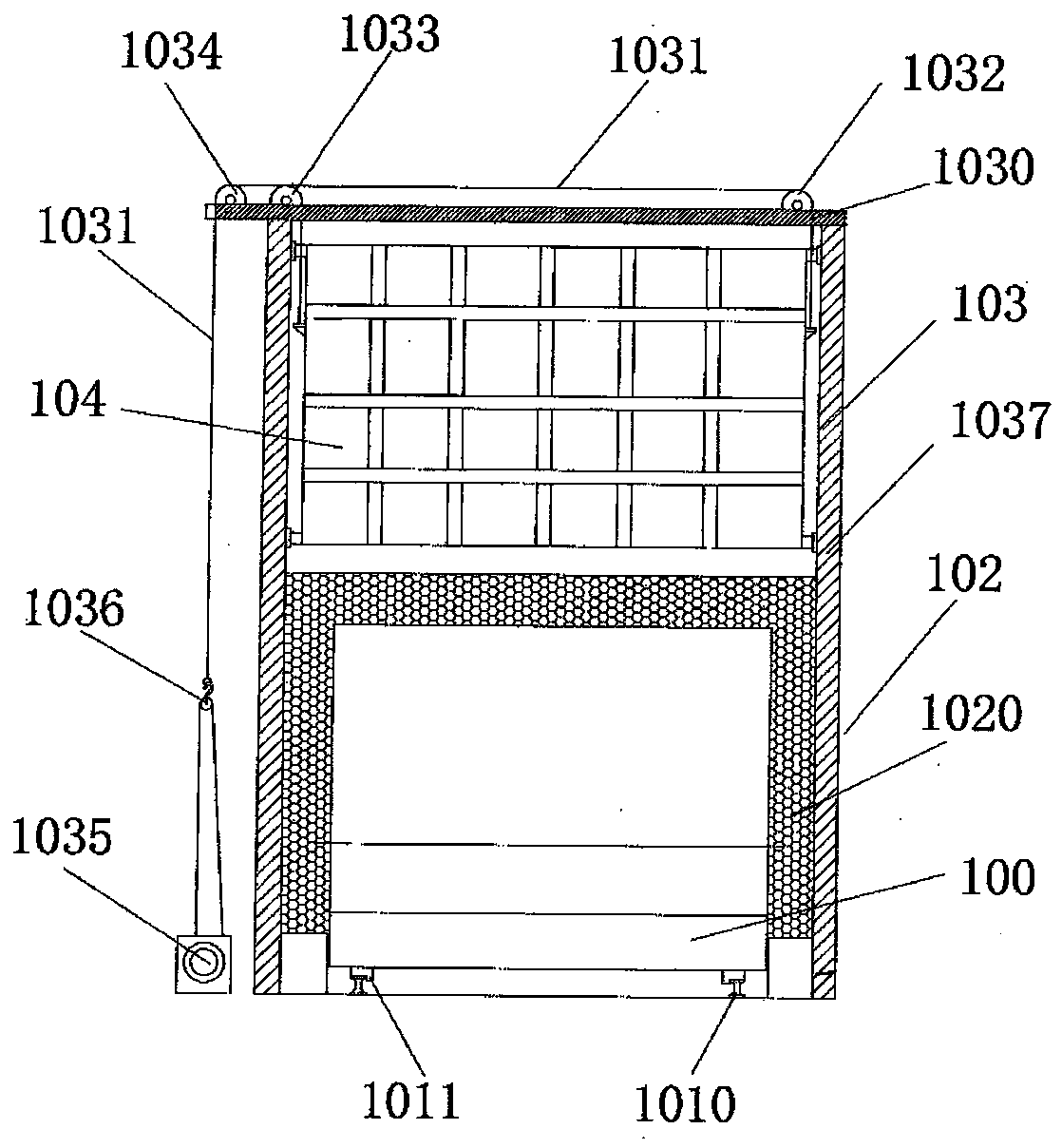

[0040] like Figure 1-20 As shown, an environment-friendly special furnace for melting EPS lost foam includes a melting device and a purification device. device 7, activated carbon adsorption box 9, photo-oxygen catalytic purifier 11 and induced draft fan 13, the water mist spray purifier 3, winnowing dust collector 5, bag filter 7, activated carbon adsorption box 9, photo-oxygen catalytic purifier 11 and the induced draft fan 13 are sequentially connected by pipelines. The pipeline includes a first connecting pipeline 2, a second connecting pipeline 4, a third connecting pipeline 6, a fourth connecting pipeline 8, a fifth connecting pipeline 10, a sixth connecting pipeline 12 and a water vapor discharge pipe 14. One end of the connecting pipe 2 is located above the melting furnace 1, and is connected to the draft outlet 108 on the melting furnace 1 through a flange, and the other end of the first connecting pipe 2 is located at the lower end of the water mist spray purifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com