Environment-friendly cement feeding and conveying device and cement mixing pile construction system

An environmentally friendly, cement-based technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as low production efficiency, pollution of crops, fish ponds and shrimp ponds, and inability to overcome back-sizing, so as to improve the quality of piles, High practical value and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

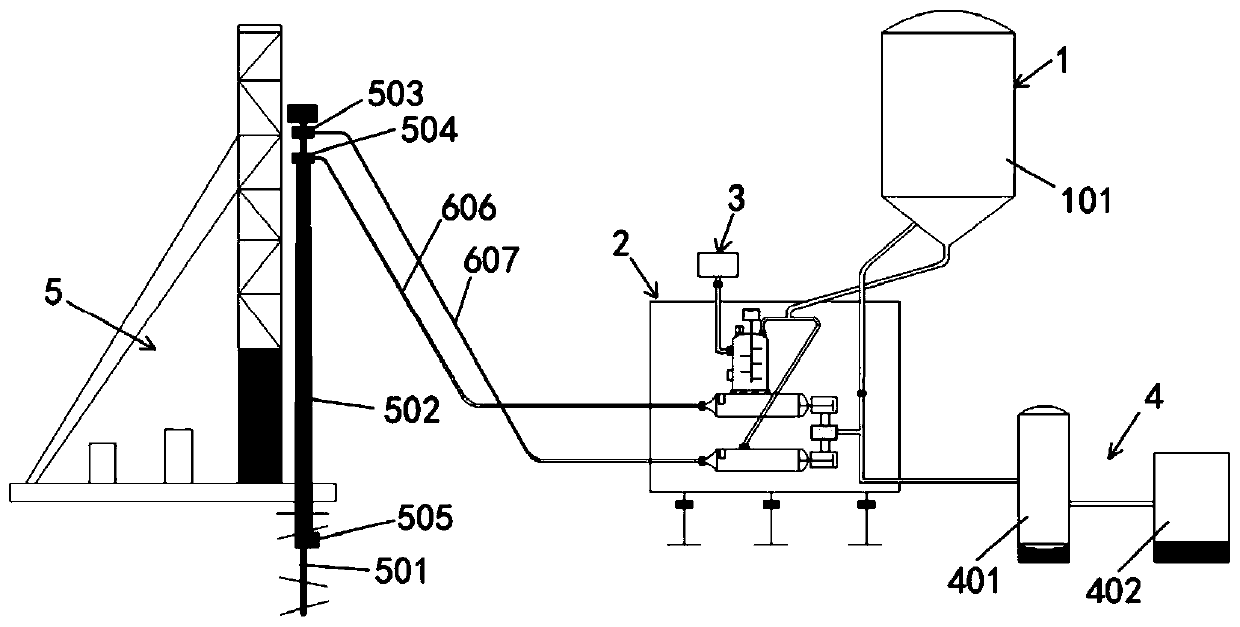

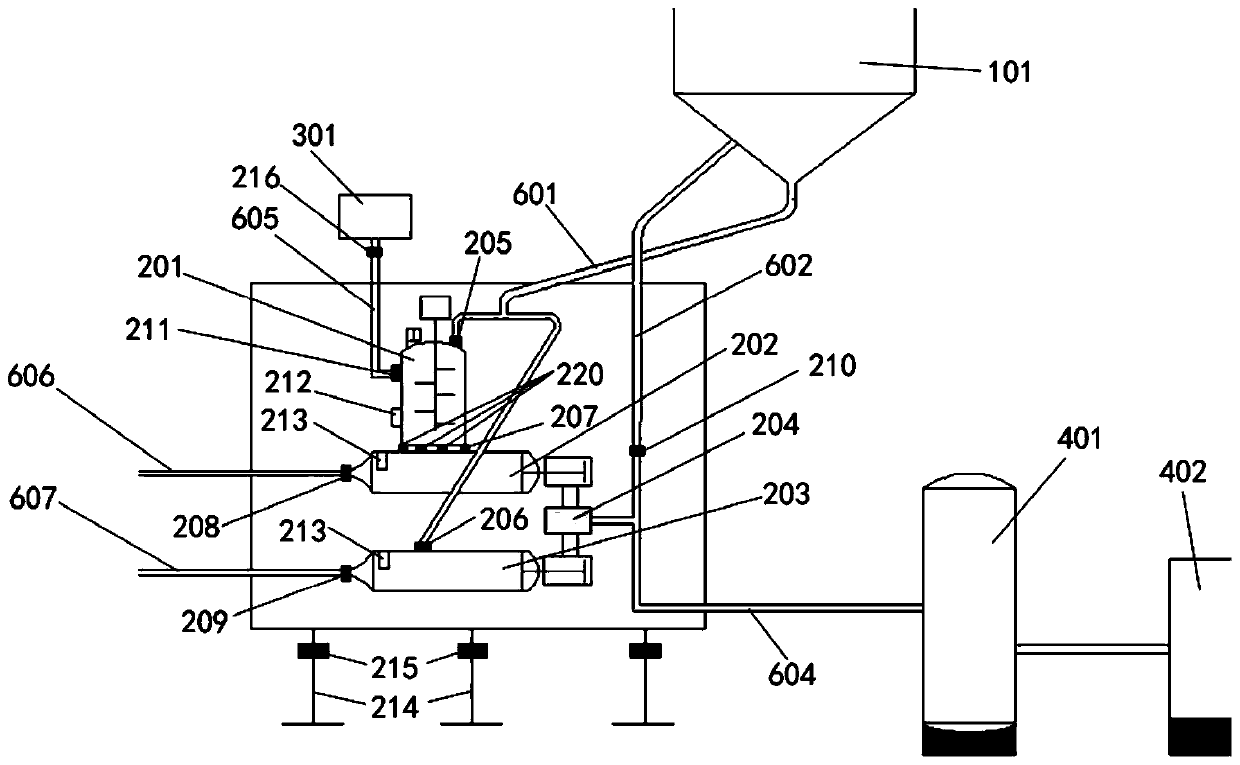

[0041] Such as figure 1 As shown, this embodiment provides a cement mixing pile construction system, including a cement mixing pile machine 5 and a cement conveying device.

[0042]The cement mixing pile driver 5 includes an inner drill rod 501 and an outer drill rod 502 nested with each other. The inner drill rod 501 is hollow inside, and the upper end is provided with a first sealing collar 503 for connecting the powder delivery pipe 607 . The outer drill pipe 502 is sleeved on the outer ring of the inner drill pipe 501 , and the end of the outer drill pipe 502 is provided with a second sealing collar 504 for connecting the slurry delivery pipe 606 . Bottoms of the inner drill rod 501 and the outer drill rod 502 are provided with spray ports and rotating blades. A dry humidity sensor 505 is also installed at the lower end of the outer drill rod 502 .

[0043] The cement delivery device includes a cement storage module 1 , a cement upper feeding module 2 , a liquid pump mo...

Embodiment 2

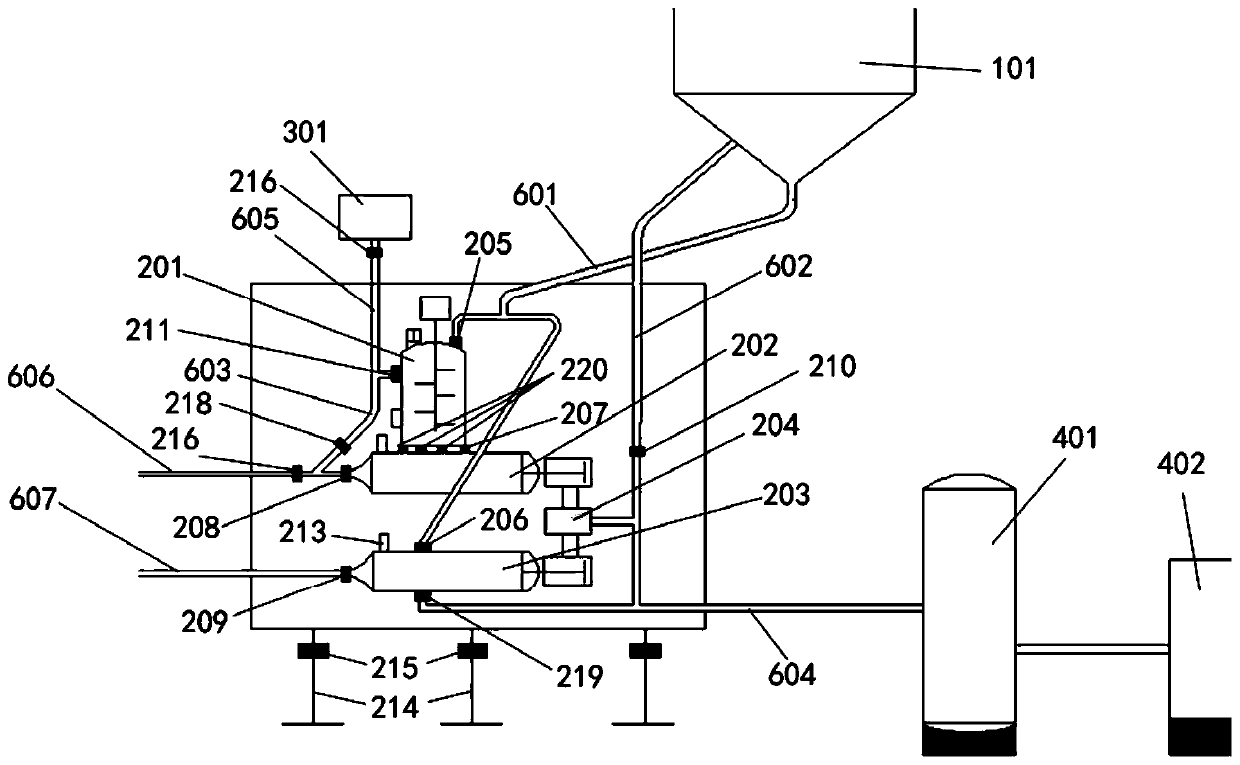

[0064] Such as image 3 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, and the difference lies in:

[0065] The water outlet connection pipe 605 and the slurry delivery pipe 606 are connected through the third connection pipe 603 and the water delivery control valve 218 . The intake connecting pipe 604 is also connected to the powder delivery power unit 203 through the intake control valve 219 . A flow controller 216 is added on the slurry delivery pipe 606 .

[0066] In the construction process of this embodiment, the powder feeding power unit 203 not only controls the powder feeding through the conversion control valve 204 and the powder feeding control valve 209, but also opens the intake control valve 219 during the powder feeding process to increase the powder feeding power The pressure in the unit 203 increases the efficiency of the powder conveying power unit 203 for conveying cement powder to the powder conveying pipe 607 . Aft...

Embodiment 3

[0069] Such as Figure 4 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, and the difference lies in:

[0070] The cement storage module 1 includes a storage tank 102 and a bagged cement feed tank 103 . The lower end of the storage tank 102 has a tapered structure, and is connected to the first connecting pipe 601 and the second connecting pipe 602 in the same manner as the bulk cement storage tank 101 in the first embodiment. The bagged cement feed tank 103 is connected to the storage tank 102 through a transfer pipe 104, and the transfer pipe 104 is provided with a feeding control valve 105. The air pump module 4 is connected to the upper end of the bagged cement feeding tank 103 by the air inlet connecting pipe 604, and in the air inlet connecting pipe 604, the connecting pipe part connecting the bagged cement feeding tank 103 is provided with a pressure control valve 106, and the storage Tank 102 is a container provided with a vent fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com