Culture method of golden fungus fruiting bodies through fusion and concrescence

A technology of golden ear fruiting body and cultivation method, applied in cultivation, plant cultivation, mushroom cultivation and other directions, can solve the problems of inappropriate facility, factory fruiting, long cultivation period, irregular fruiting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

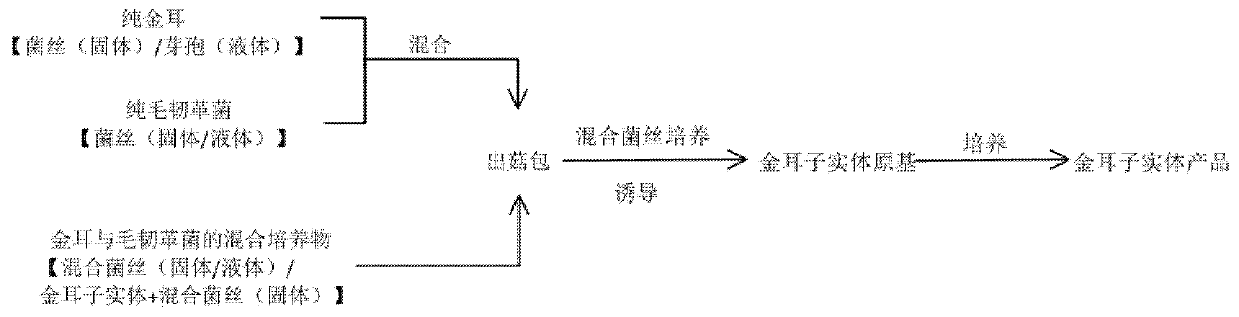

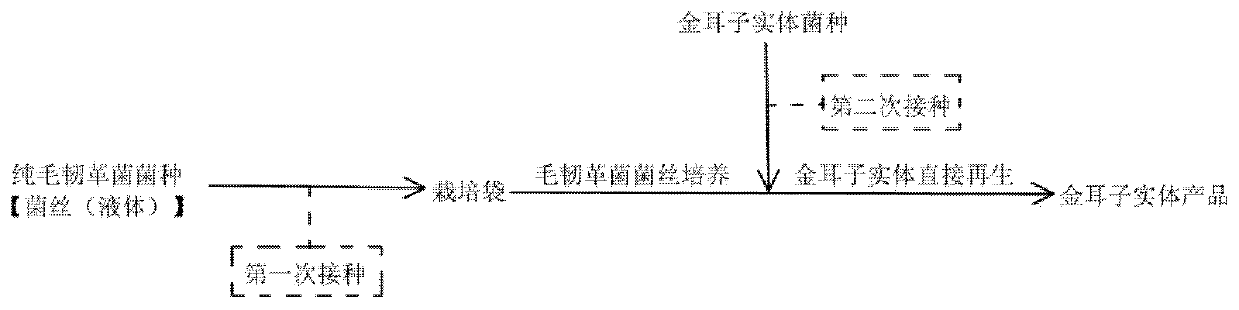

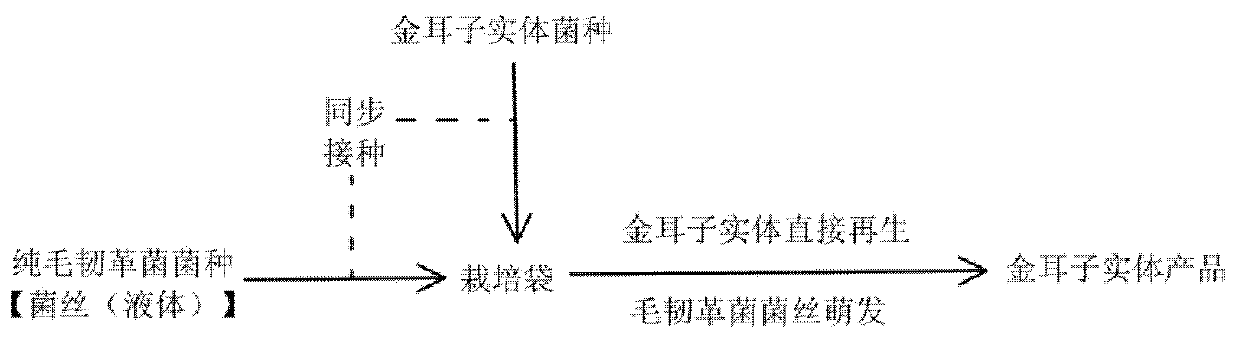

Method used

Image

Examples

Embodiment 1

[0046] 1 strain production

[0047] 1.1 Production of mother species

[0048] 1.1.1 Preparation of mother seed medium

[0049] 1.1.1.1 Mother solid medium formula (1L):

[0050] Potato 200g, sucrose 20g, agar powder 20g, KH 2 PO 4 4g, MgSO 4 3g.

[0051] 1.1.1.2 Formula of stock liquid medium (1L):

[0052] Potato 200g, sucrose 20g, KH 2 PO 4 4g, MgSO 4 3g.

[0053] 1.1.1.3 Preparation method of mother seed medium:

[0054] Calculate the dosage of each component according to the preparation amount, weigh the peeled and sliced potatoes, add water and boil for 15 minutes, then filter with 4 layers of gauze to obtain the filtrate, accurately weigh each medicine, put it into a container that can be fixed, add the filtrate and adjust the volume to the prepared amount , Stir to fully dissolve and evenly disperse various medicines. For the production of petri dishes, divide them into Erlenmeyer flasks and seal them with a gas-permeable film, and then sterilize them ...

Embodiment 2

[0120] 1 strain production

[0121] 1.1 Production of mother species

[0122] 1.1.1 Preparation of mother seed medium

[0123] 1.1.1.1 Mother solid medium formula (1L):

[0124] Soybean powder 5g, sucrose 20g, agar powder 20g, KH 2 PO 4 4g, MgSO 4 3g.

[0125] 1.1.1.2 Formula of stock liquid medium (1L):

[0126] Soybean powder 5g, sucrose 20g, KH 2 PO 4 4g, MgSO 4 3g.

[0127] 1.1.1.3 Preparation method of mother seed medium:

[0128] Calculate the dosage of each component according to the preparation amount, accurately weigh each drug, put it into a container that can be constant, add water and set the volume to the preparation amount, stir to fully dissolve and evenly disperse each drug. Put the petri dishes into Erlenmeyer flasks and seal them with a gas-permeable film, then sterilize them with damp heat and high pressure (121°C) for 25 minutes, and then put them on the ultra-clean bench while they are still hot and put them into sterile petri dishes, and th...

Embodiment 3

[0194] 1 strain production

[0195] 1.1 Production of mother species

[0196] 1.1.1 Preparation of mother seed medium

[0197] 1.1.1.1 Mother solid medium formula (1L):

[0198] Yeast powder 5g, glucose 20g, agar powder 20g, KH 2 PO 4 4g, MgSO 4 3g.

[0199] 1.1.1.2 Formula of stock liquid medium (1L):

[0200] Yeast powder 5g, glucose 20g, KH 2 PO 4 4g, MgSO 4 3g.

[0201] 1.1.1.3 Preparation method of mother seed medium:

[0202] Calculate the dosage of each component according to the preparation amount, accurately weigh each drug, put it into a container that can be constant, add water and set the volume to the preparation amount, stir to fully dissolve and evenly disperse the various drugs. Put the petri dishes into Erlenmeyer flasks and seal them with a gas-permeable film, then sterilize them with damp heat and high pressure (121°C) for 25 minutes, and then put them on the ultra-clean bench while they are still hot and put them into sterile petri dishes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com