Gas-liquid reaction method and gas-liquid reaction device for entering reaction preparation state in advance

A gas-liquid reaction, ready state technology, applied in feeding devices, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, etc., can solve the problem of low gas content in the reactor, reaction conversion rate and selectivity Low cost and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

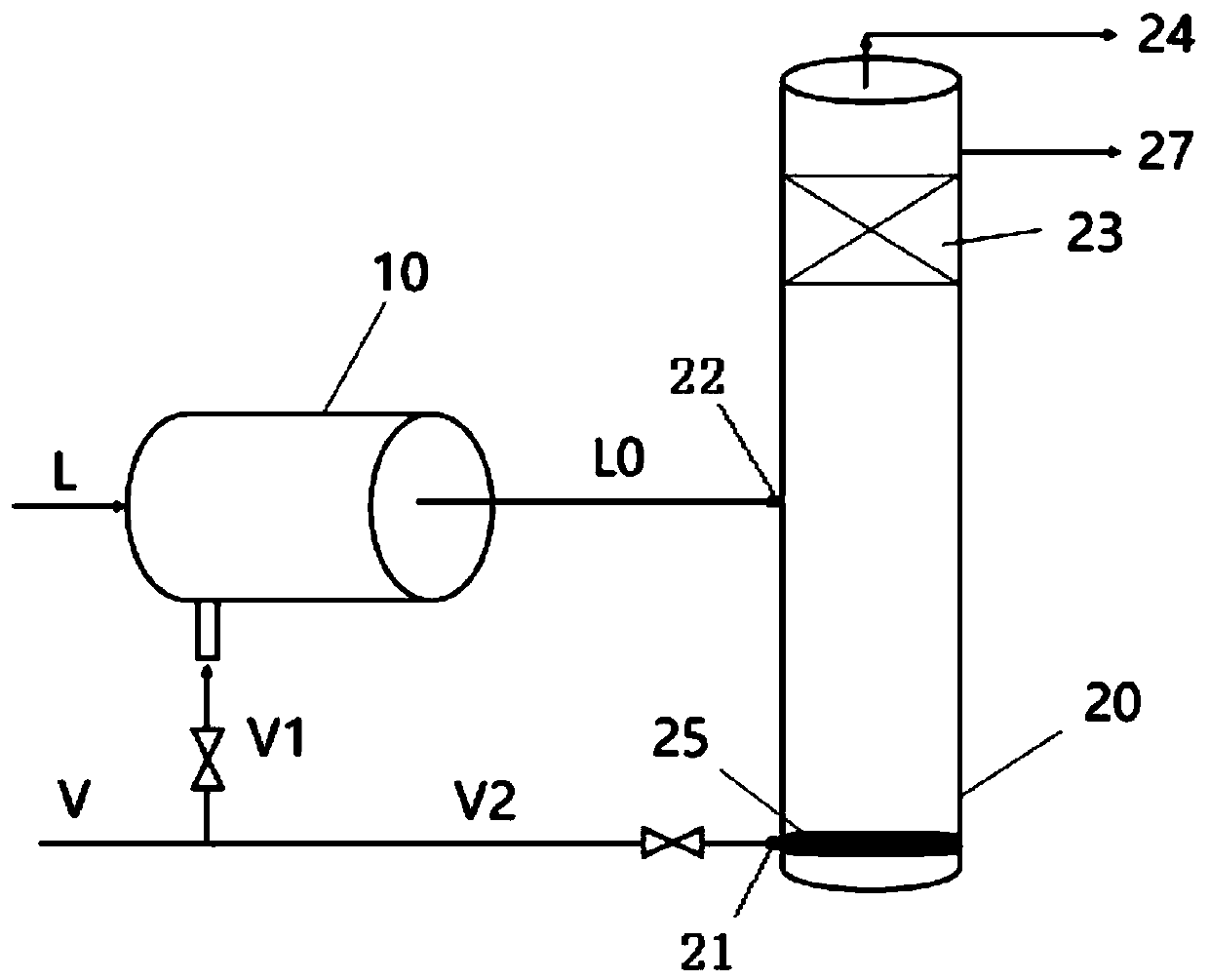

[0071] Embodiment 1, a kind of gas-liquid reaction device

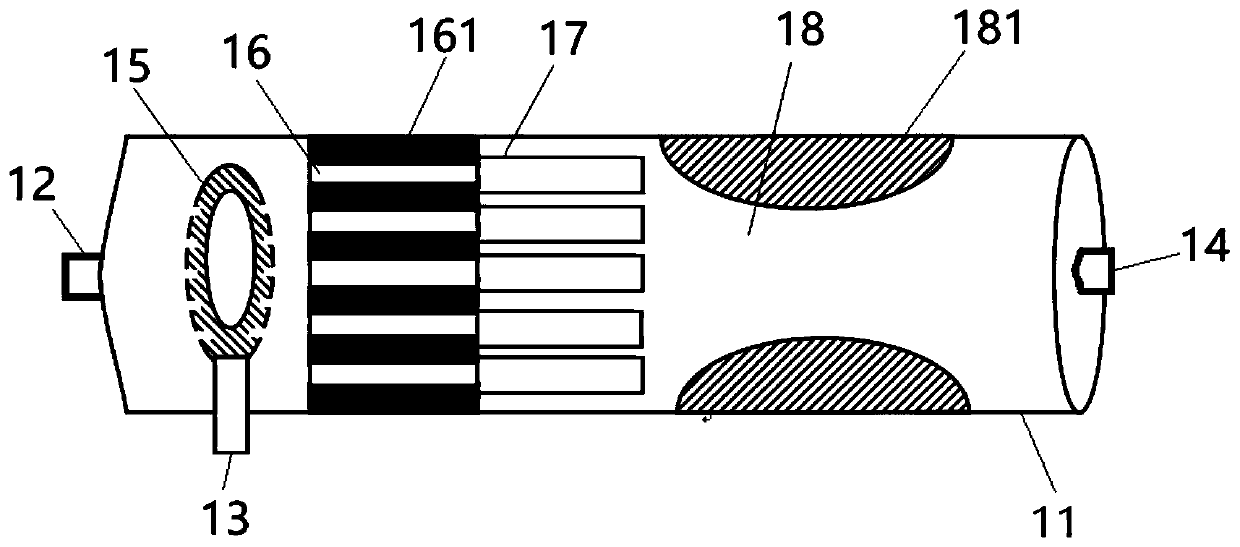

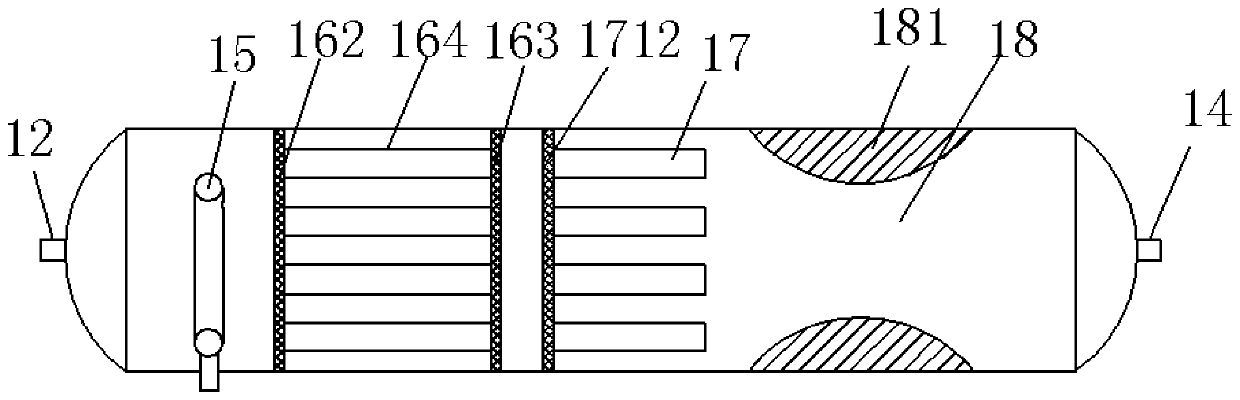

[0072] Such as Figure 1 to Figure 4As shown, the present embodiment provides a gas-liquid reaction device, including a hydraulic premixer 10, and a reactor 20 connected to the hydraulic premixer 10; the gas phase feed branch V is part of the gas phase feed V1 and Main process gas phase feed V2; per unit time, the amount of the part of the gas phase feed V1 is 1.01 to 2 times the gas phase amount required to make the liquid phase feed L reach the gas phase saturation concentration. in:

[0073] The hydraulic premixer 10 includes a cylinder 11, a liquid phase feed port 12 and a gas phase feed port 13 arranged at one end of the cylinder 11, and a premixed material arranged at the other end of the cylinder 11. The discharge port 14; the liquid phase feed L is connected with the liquid phase feed port 12, and the part of the gas phase feed V1 is connected with the gas phase feed port 13; The direction from the liquid p...

Embodiment 2

[0112] Embodiment 2, a kind of gas-liquid reaction device

[0113] Such as Figure 5 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, the difference is:

[0114] The lower part of the reactor 20 is provided with a gas distributor 25 and a liquid velocity distribution unit 26 sequentially from bottom to top, and the gas phase feed V2 of the main process enters the reactor 20 from the gas phase feed port 21 of the main process, and passes through The gas distributor distributes 25 ; the premixed material enters the reactor 20 from the premixed material inlet 22 and is distributed through the liquid velocity distribution unit 26 .

[0115] The liquid velocity distribution unit 26 includes a unit body 262, the unit body 262 is provided with a unit inlet and several liquid velocity distribution outlets, the unit inlet is connected to the premixed material feed port 22, and the liquid velocity The distribution outlet is provided with a discharg...

Embodiment 3

[0126] Embodiment 3, effect detection

[0127] The devices of Example 1 and Example 2 and the traditional bubble reactor device were used for comparative tests respectively. The reaction process of conventional bubble reactor is as follows: Figure 6 shown.

[0128] (1), carry out self-catalyzed oxidation reaction---cumene is oxidized into cumene hydroperoxide. The process and parameters are as follows:

[0129] Oxidation of cumene to cumene hydroperoxide Reaction conditions: reaction temperature 110°C, reaction pressure 0.6MPa, gas-liquid ratio 9:1.

[0130] A plexiglass cylinder with an inner diameter of 180mm and a height of 2000mm was used as a reactor for the test. The inside of the main reaction control unit 23 is an empty cylinder, without packing or catalyst layer.

[0131] The inner diameter D of the cylinder of the hydraulic premixer 10 is 50 mm, the total length is 2000 mm, and there are 10 high-speed flow channels, and the inner diameter of each high-speed flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com