Separation device, system and separation method based on particle size of water abrasive

A separation device and water abrasive technology, applied in solid separation, chemical instruments and methods, springs/shock absorbers, etc., can solve problems such as low efficiency and unclean washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

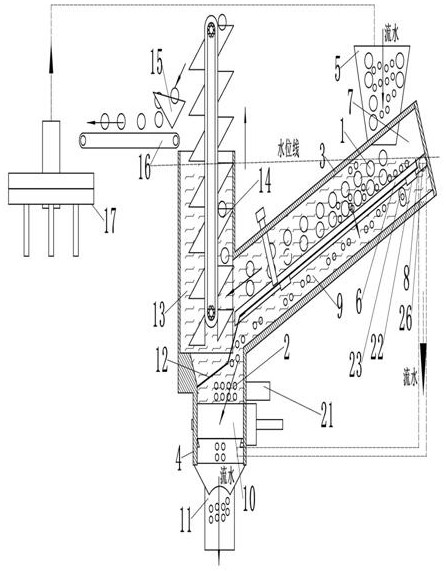

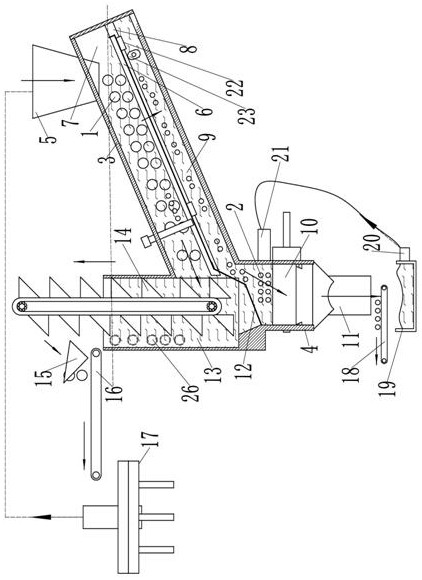

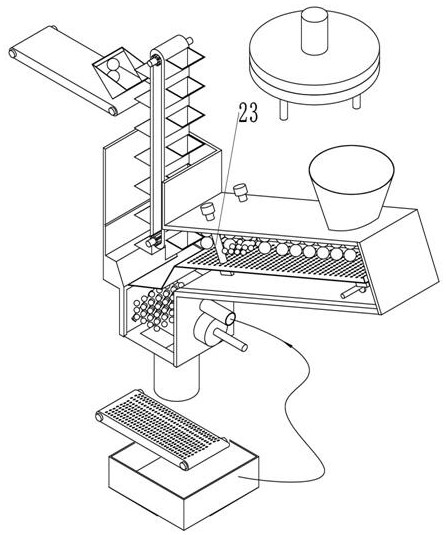

[0052] Such as Figure 1-7 As shown, the solutions in the embodiments of the present invention can be used in reasonable combination. The water abrasive separation device based on the particle size of the present embodiment includes a water screen box 3, which is an assembly, and its shape can be changed reasonably according to actual use. The upper end is connected to the lower end of the water screen box 3. The blanking box 4 is here For the convenience of description, it can be used as a part of the water screen box 3, thereby simplifying the structure, the separation screen 6 arranged in the water screen box 3 realizes the separation of particles, and is arranged on the water screen box 3 and used to send The feeding place 5 of the large particle material 1 (this is the assembly, which can be several kinds of particles) and the small particle material 2; thus the material particles to be separated are fed.

[0053] The aperture of the separating screen 6 is larger than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com