A simple basic platform for rolling test

A basic platform and simple technology, applied in the direction of metal rolling, metal rolling, metal rolling stand, etc., to achieve the effect of easy disassembly, low manufacturing cost, and improved feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The simple rolling test base platform of the present invention will be further described below according to the specific embodiments of the present invention and the accompanying drawings, but this description does not constitute an improper limitation of the present invention.

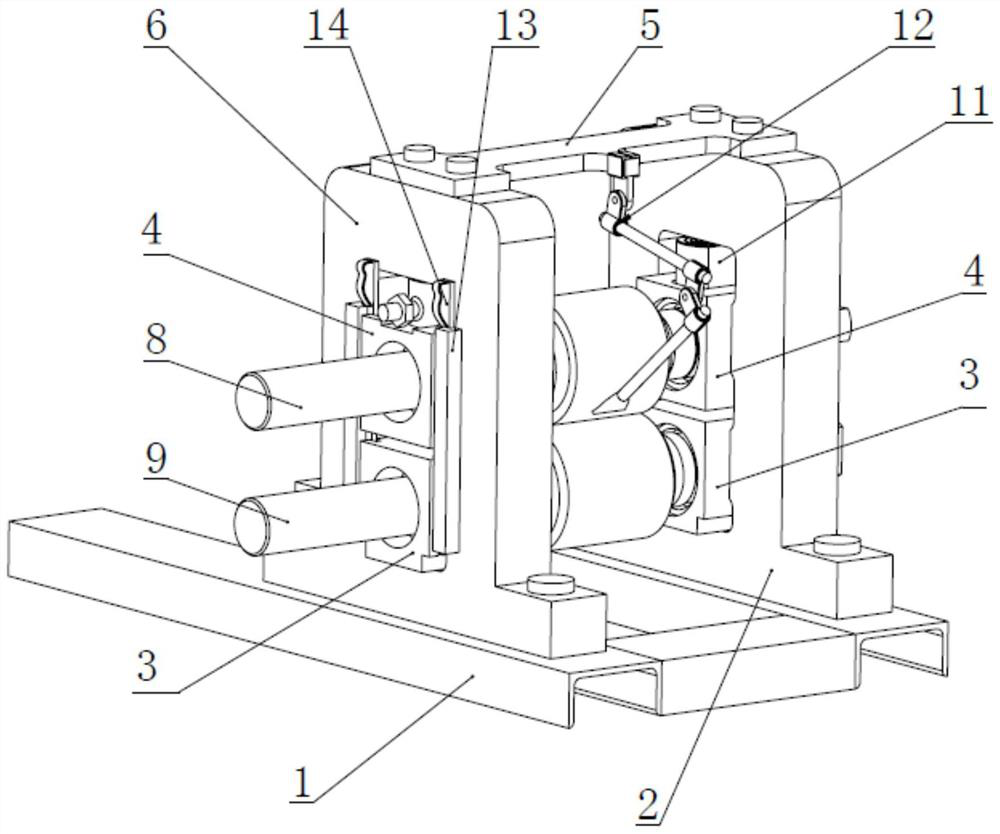

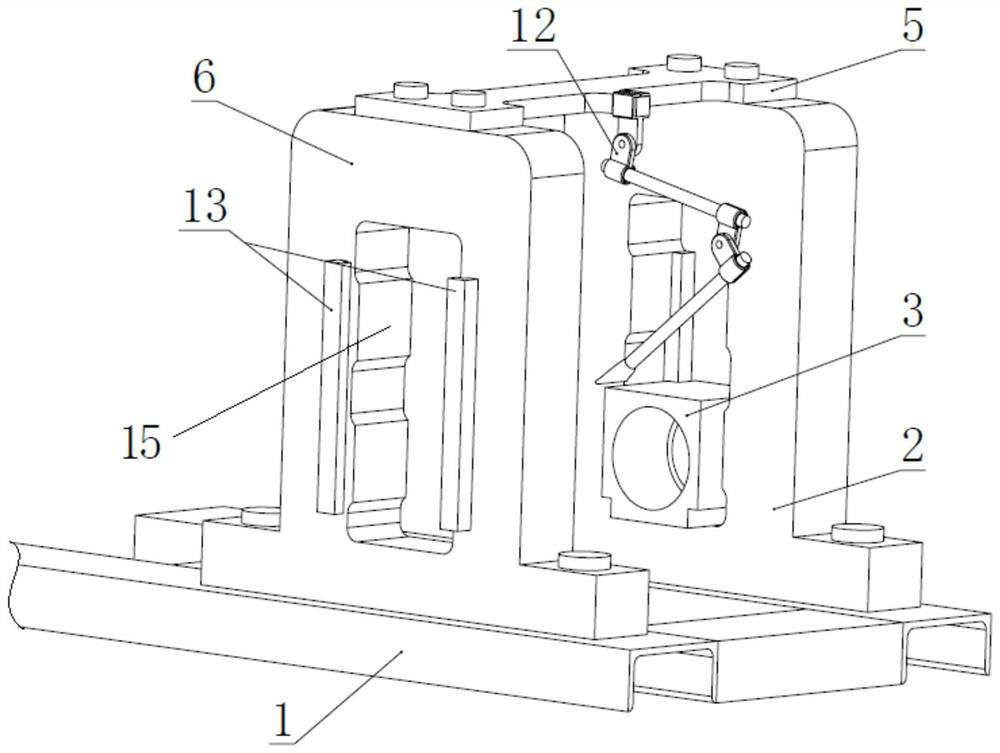

[0045] figure 1 It is a structural schematic diagram of a simple rolling test basic platform in an embodiment of the present invention. figure 2 Some elements of the simple rolling test basic platform described in the present invention are shown.

[0046] combine figure 1 and figure 2 It can be seen that in this embodiment, the simple rolling test basic platform includes a support frame, a pair of first bearing housings 4, a second bearing housing 3, a pressing device 11, and a lubrication mechanism 12, wherein the supporting frame It includes a base 1 , a first archway 6 and a second archway 2 erected on the base 1 and a crossbeam 5 connected between the first archway 6 and the second archw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com