Unreinforced self-reinforced cement-based printing concrete and preparation method thereof

A cement-based, concrete technology, applied in the direction of manufacturing tools, ceramic molding machines, additive processing, etc., can solve the problems of unfavorable self-supporting, unfavorable interlayer bonding, high work performance, etc., to achieve good environmental and ecological benefits, configuration The technology is simple and efficient, promoting the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

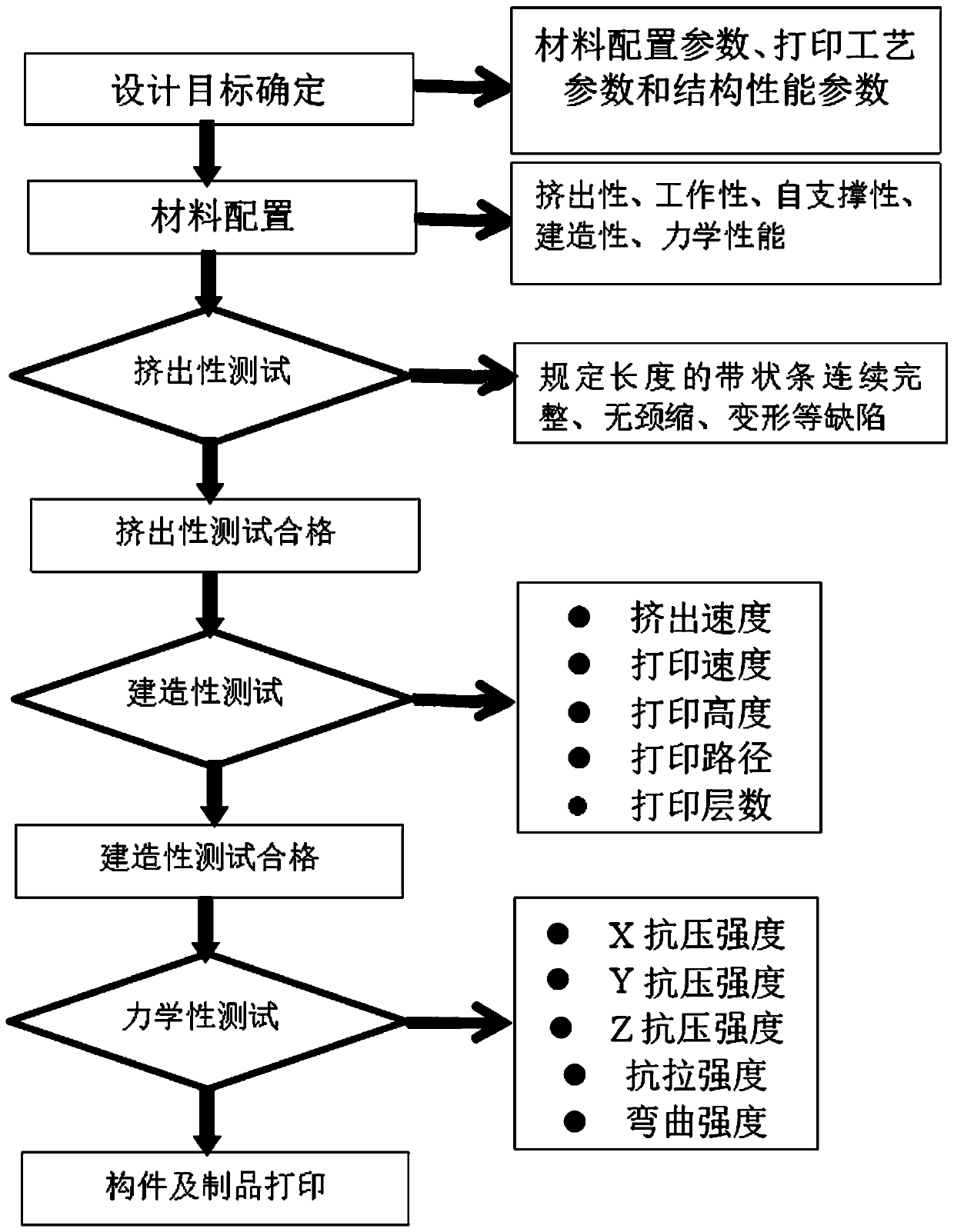

Method used

Image

Examples

Embodiment 1

[0092] A kind of unreinforced self-reinforced cement-based printed concrete, comprising the following components with mass per unit volume:

[0093] Cemented mixed material: 100 parts;

[0094] Among them, the cemented mixed materials include: 50 parts of cement, 42 parts of fly ash, and 8 parts of aluminum-calcium cement;

[0095] Active admixture: 10 parts;

[0096]6 parts of composite mineral admixture, 4 parts of silica fume.

[0097] Chemically modified material: 2.0 parts;

[0098] Among them, the chemically modified materials include: 0.5 part of clay powder, 1 part of high-efficiency large-scale plasticizer, and 0.5 part of mineral admixture.

[0099] Aggregate: 120 parts;

[0100] Water: 40 parts;

[0101] Fiber: The blending amount is 2.0kg / m3.

[0102] The cement in the above-mentioned cementitious mixture is Portland cement with a strength grade of 52.5MPa;

[0103] The fly ash in the above-mentioned cemented mixed materials is Class F fly ash, the fineness ...

Embodiment 2

[0119] A kind of unreinforced self-reinforced cement-based printed concrete, comprising the following components with mass per unit volume:

[0120] Cemented mixed material: 100 parts;

[0121] Among them, cementing mixed materials include: 65 parts of cement, 30 parts of fly ash, 5 parts of aluminum-calcium cement; 12 parts of active admixture; 7.2 parts of composite mineral admixture, 4.8 parts of silica fume. Chemically modified materials: 2.1 parts;

[0122] Among them, chemical modification materials include: 0.3 parts of clay powder, 1.3 parts of high-efficiency large-scale plasticizer, and 0.5 parts of mineral admixture.

[0123] Aggregate: 110 parts;

[0124] Water: 43 parts;

[0125] Fiber: The blending amount is 1.5kg / m3.

[0126] The cement in the above-mentioned cementitious mixture is Portland cement with a strength grade of 52.5MPa;

[0127] The fly ash in the above-mentioned cemented mixed materials is Class F fly ash, the fineness (45μm sieve) ≤ 30%, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com