High-thermal-conductivity silicon nitride ceramic and preparation method thereof

A technology of silicon nitride ceramics and high thermal conductivity, applied in the field of ceramics, can solve the problem of low thermal conductivity of silicon nitride ceramics, and achieve the effects of good bonding effect, high green body strength and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A silicon nitride ceramic with high thermal conductivity and a preparation method thereof, comprising the following steps:

[0032] Step 1, graded mixing 1, silicon nitride powder and alcohol are mixed, wherein the amount of silicon nitride powder added accounts for 90.2%-96.7% of the total solid raw material (silicon nitride and silicon nitride magnesium) quality, continue to add Overall solid raw material mass fraction 3.3%-9.8% magnesium silicon nitride, the mixing frequency in the horizontal mill is 41Hz, and the mixing time is 24h; continue to add binder PVB and additives (orthosilicic acid, n-octanoic acid, phosphoric acid and oil acid mixture), wherein the ratio of the mass of the binder to the mass of the silicon nitride powder is 1.4:98.6, and the ratio of the mass of the additive to the mass of the silicon nitride powder is 6.9:93.1. The mixing time was 24 h at a frequency of 50 Hz in a vertical mill. The mass ratio of orthosilicic acid, n-octanoic acid, phos...

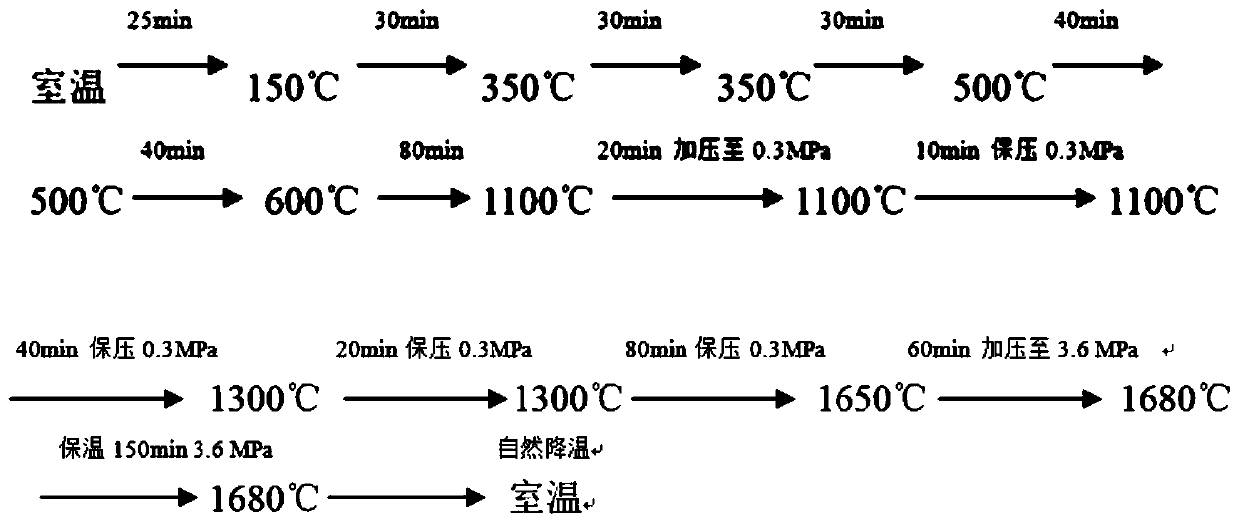

Embodiment 1

[0041] Contains the following steps:

[0042] Step 1, graded mixing 1, mix silicon nitride powder and alcohol with a mass ratio of 1:2.4, the mixing frequency in a horizontal grinder is 41Hz, and the mixing time is 24h; continue to add PVB and the above-mentioned silicon nitride The powder mass ratio is 0.6:99.4, the frequency in the vertical mill is 50Hz, and the mixing time is 24h.

[0043] Step 2, spray granulation and pressure molding, spray granulation of the mixture produced by graded mixing 2, after granulation, press it into a block with a pressure of 50MPa, then put it into a vacuum bag for vacuuming, and put it in a cold storage tank after pumping. Add a pressure of 200MPa to the static press, hold the pressure for 2min, release the pressure to 140MPa, hold the pressure for 1min, release the pressure to 70MPa, and hold the pressure for 40s.

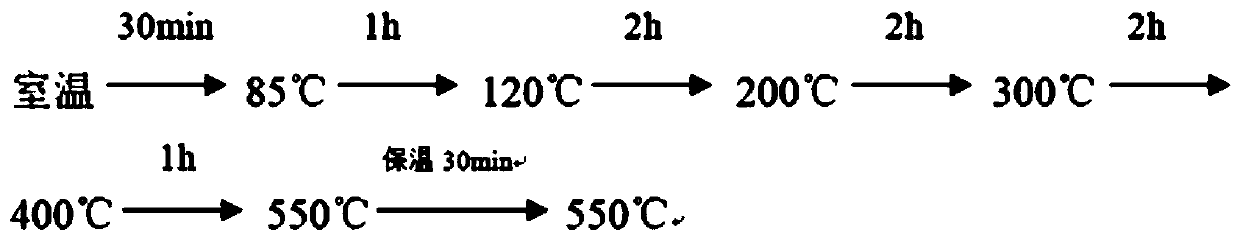

[0044] Step 3, drying and degreasing: put the biscuit in Step 3 into an oven, and dry at 80°C for 12 hours;

[0045] Step 4,...

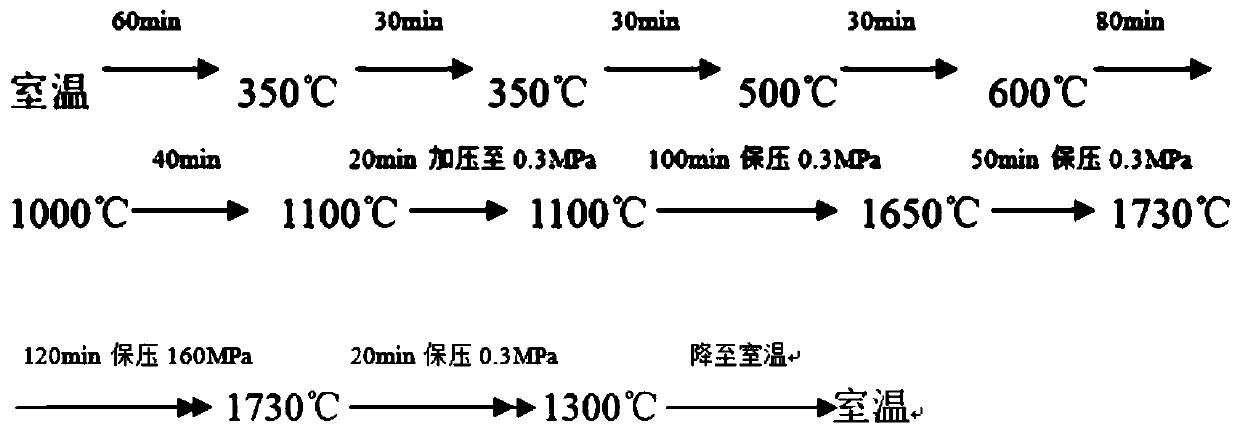

Embodiment 2

[0047] Contains the following steps:

[0048] Step 1, graded mixing 1, mix silicon nitride powder and alcohol with a mass ratio of 1:2.4, the mixing frequency in a horizontal grinder is 41Hz, and the mixing time is 24h; continue to add PVB and the above-mentioned silicon nitride The powder mass ratio is 1.0:99.0, the frequency in the vertical mill is 50Hz, and the mixing time is 24h.

[0049] Step 2, spray granulation and pressure molding, spray granulation of the mixture produced by graded mixing 2, after granulation, press it into a block with a pressure of 50MPa, then put it into a vacuum bag for vacuuming, and put it in a cold storage tank after pumping. Add a pressure of 200MPa to the static press, hold the pressure for 2min, release the pressure to 140MPa, hold the pressure for 1min, release the pressure to 70MPa, and hold the pressure for 40s.

[0050] Step 3, drying and degreasing: put the biscuit in Step 3 into an oven, and dry at 80°C for 12 hours;

[0051] Step 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com