A kind of ceramic atomizing core for electronic cigarette and its preparation method and application

An atomizing core and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of uneven heating, unfavorable industrialization development and market promotion of electronic cigarettes, poor smoke taste, etc., to overcome uneven heating and high compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The weight ratio of each raw material in the preparation process of the atomizing core of the present invention is:

[0039] Monomer: Crosslinker: Dispersant: Solvent: Silicon Nitride Powder: Silicon Oxide Powder: Sintering Aid: Initiator = (20-27): (4-7): (1-1.8): 100: (10 -20):(30-50):(5-10);

[0040] The preparation process is:

[0041] 1. Monomer acrylamide, crosslinking agent N,N'-methylenebisacrylamide, dispersing agent ammonium polyacrylate and solvent deionized water) by weight (20~27): (4~7): (1 ~1.8): 100 mixed to prepare a premix;

[0042]2. Add (10-20) parts by weight of silicon nitride powder, (30-50) parts by weight of silicon oxide powder and (5-10) parts by weight of sintering aids (silicon oxide, magnesium oxide and calcium carbonate) into the premix. composition, 1:3:7);

[0043] 3. After adding (10-20) parts by weight of initiator ammonium sulfate, adjust the pH to 9-12 with an aqueous solution containing 25%-28% ammonia, and ball mill for 3-5 hou...

Embodiment 1

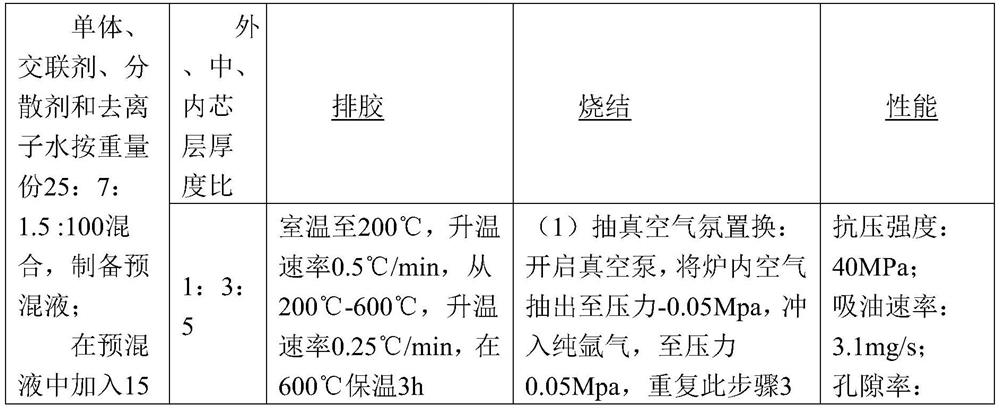

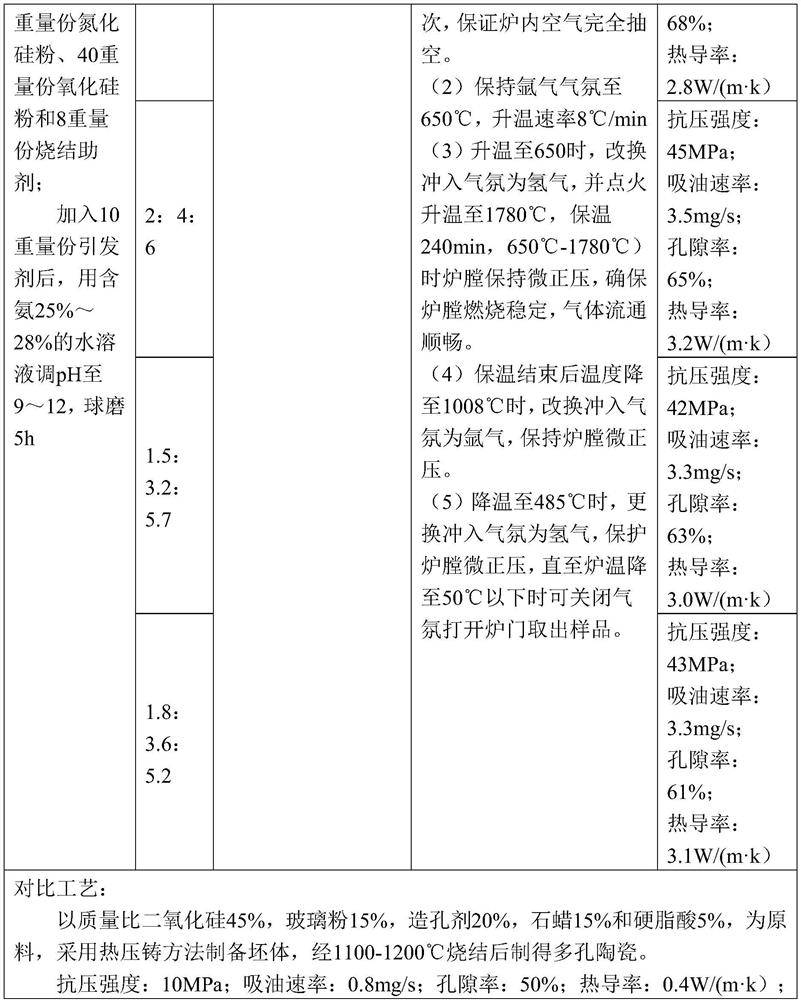

[0052] Example 1: Comparison of the present invention and conventional single ceramic powder

[0053] The present invention and the comparative example process and technical effect comparison are shown in Table 1 below, and each embodiment parameter in the table can be combined or replaced with other embodiment parameters;

[0054] Table 1

[0055]

[0056]

[0057] It can be seen from Table 1 that the compressive strength of the porous ceramic atomizing core prepared by the present invention is 40-45MPa, the oil absorption rate is 3.1-3.5mg / s, the porosity is 60-70%, and the thermal conductivity is 2.8-3.2W / (m·k); while conventionally use silica, glass frit 10-20, pore-forming agent (polystyrene microspheres), solvent (paraffin) and modifier (stearic acid) as raw materials for sintered atomization The core has a compressive strength of 10MPa, an oil absorption rate of 0.8mg / s, a porosity of 50%, and a thermal conductivity of 0.4W / (m·k). The porous ceramic atomizing c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com