Silicon nitride ceramic material and preparation method thereof

A technology of silicon nitride ceramics and ceramic materials, which is applied in the field of high-performance ceramic materials, can solve the problems of low thermal conductivity of silicon nitride ceramics, high preparation price, and does not consider the research of high thermal conductivity ceramic materials, so as to improve thermal conductivity and mechanical properties, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

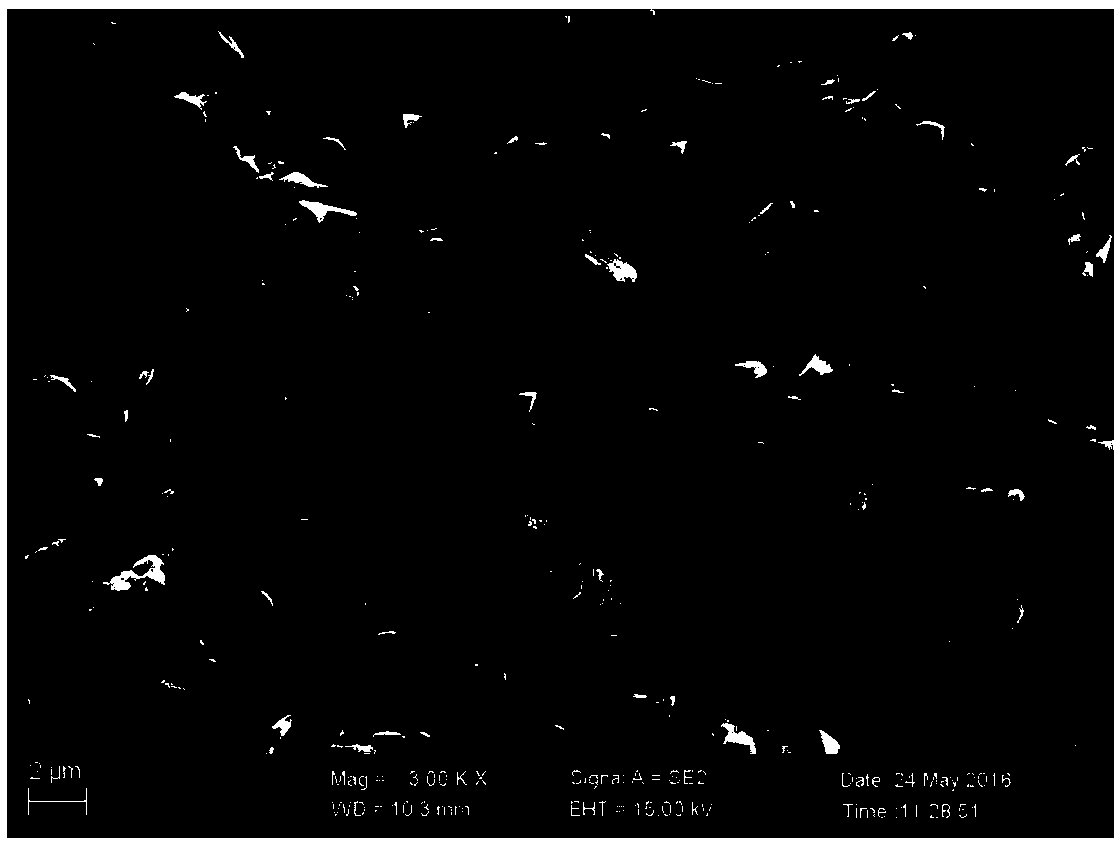

Image

Examples

Embodiment 1

[0027] Weigh silicon nitride powder, magnesium fluoride, Yb 2 o 3 , wherein, based on the total weight of solid matter, the silicon nitride powder is Si with an average particle size of 0.8 μm 3 N 4 Micropowder (a-Si 3 N 4 Content is 95% of the total weight), Yb 2 o 3 The average particle size is 0.5μm, and its purity is 99.9%; MgF 2 The average particle size is 0.5 μm, and its purity is 99.99%. Using silicon nitride grinding balls as the grinding medium and anhydrous ethanol as the mixing medium, the mixture was stirred in a stirring mill for 12 hours, and the ball-milled slurry was placed in a rotary evaporator and dried under vacuum at a temperature of 70°C. The dried powder is ground in an agate mortar and passed through an 80-mesh sieve to obtain a powder for sintering.

[0028] Put the sieved powder into a graphite mold, prefabricate the mechanical pressure of 5MPa for preforming, and then vacuumize to keep the vacuum within 16Pa, and then heat it at 1800°C and 2...

Embodiment 2

[0031] The only difference from Example 1 is that the rare earth metal oxide in this example is Er 2 o 3 , others are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0033] The only difference from Example 1 is that the rare earth metal oxide in this example is Sm 2 o 3 , others are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com