Preparation method for potash magnesium sulphate fertilizer, potassium chloride and potassium sulphate

A technology of potassium sulfate and magnesium fertilizer and potassium chloride, which is applied in the fields of alkali metal sulfite/sulfite, chemical instruments and methods, potassium fertilizer, etc., and can solve the problems of low yield of potassium chloride, retention of carnallite, and loss of potassium resources and other issues, to achieve high yield, less stringent process conditions, and reduce the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

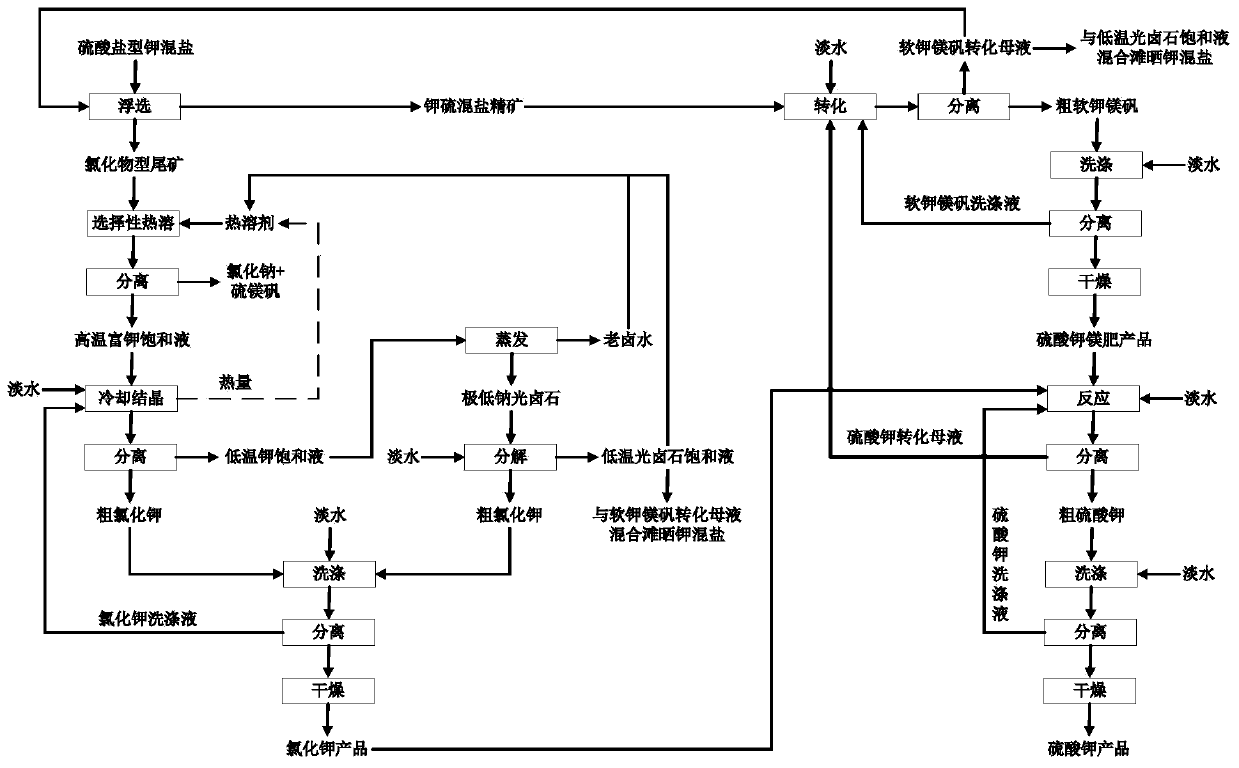

[0029] One aspect of the embodiments of the present invention provides a method for preparing potassium magnesium sulfate fertilizer, potassium chloride and potassium sulfate, comprising:

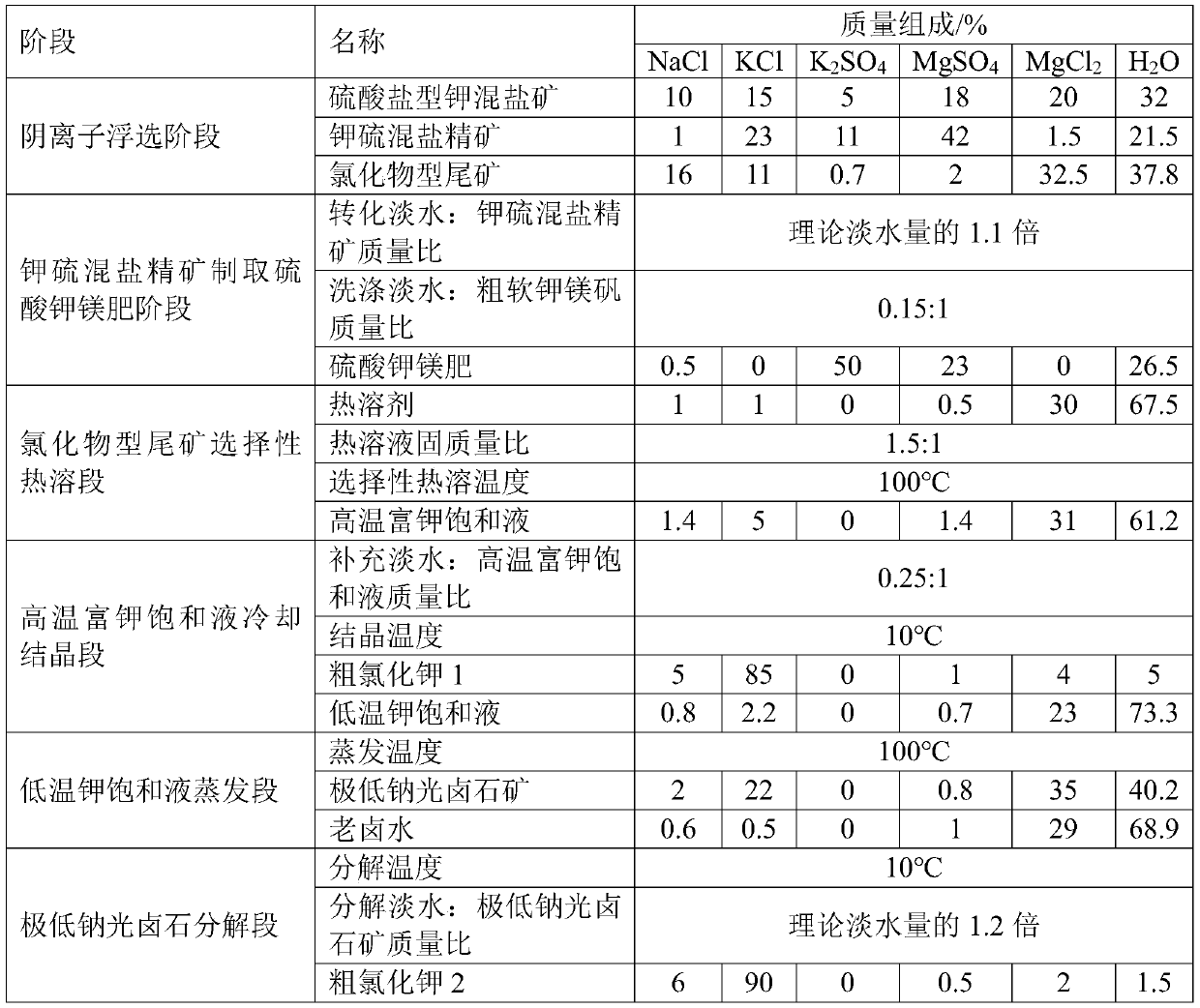

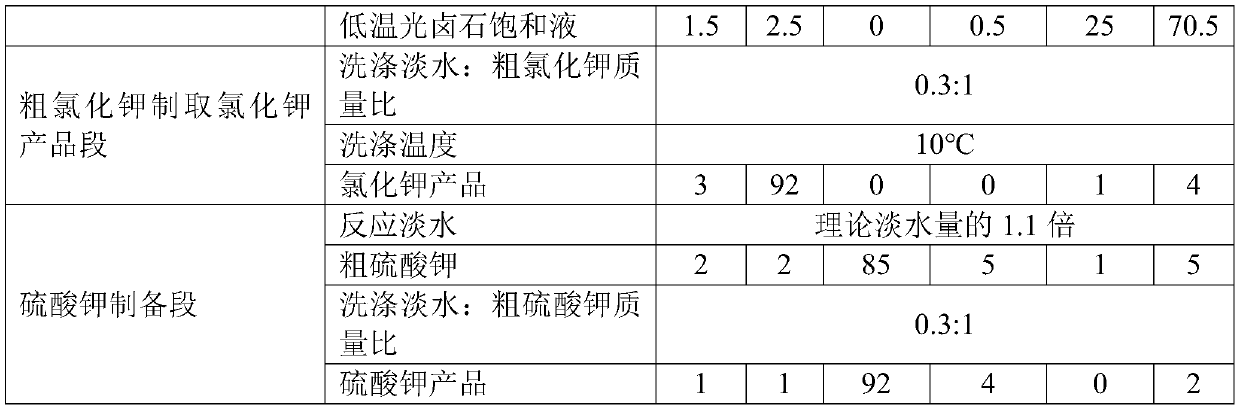

[0030] (1) Carry out flotation treatment to sulfate-type potassium mixed salt ore with anionic flotation agent to obtain potassium-sulfur mixed-salt concentrate and chloride-type tailings, wherein the potassium-sulfur mixed-salt concentrate includes The following components: NaCl 1.0~2.5wt%, KCl 23~28wt%, K 2 SO 4 3~11wt%, MgSO 4 42~47wt%, MgCl 2 0-1.5wt%, the chloride-type tailings include the following components calculated by mass percentage: NaCl 16-76wt%, KCl 6.5-11.0wt%, K 2 SO 4 0.2~0.7wt%, MgSO 4 2.0~5.5wt%, MgCl 2 4.0~32.5wt%;

[0031] (2) Contact the hot solvent with the chloride-type tailings, and perform selective heat-dissolution treatment at 75-100°C, and then separate the obtained mixture from solid-liquid to obtain high-temperature potassium-rich saturated liqui...

Embodiment 1

[0097]

[0098]

Embodiment 2

[0100]

[0101]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap