Highly-efficient back-mixing roller-type aerobic composting reaction device

A technology of aerobic composting and reaction devices, applied in fertilization devices, applications, organic fertilizers, etc., can solve the problems of slow composting of fresh materials, inoculation of fresh materials with hard-to-decompose compost, and rapid humification of difficult-to-organic waste, etc., to achieve Improve adaptability and treatment efficiency, realize rapid humification and harmlessness, and promote the effect of rapid humification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

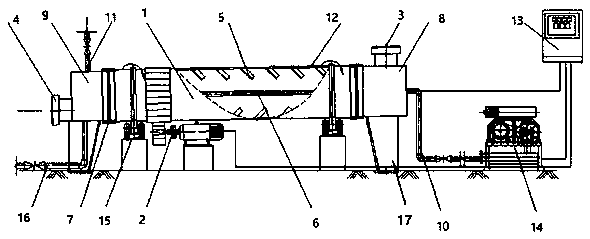

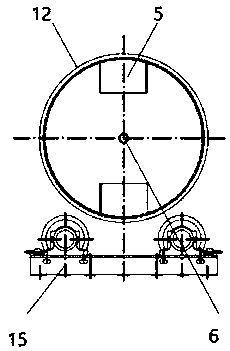

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

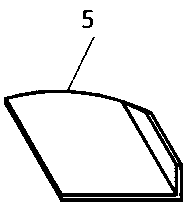

[0027] For specific implementation: see Figure 1 to Figure 4 , a high-efficiency back-mixing drum-type aerobic composting reaction device, including a rotating cylinder 1, the rotating cylinder 1 is connected to a driving device 2, and the driving device realizes the rotation around the axis, and one end of the rotating cylinder is connected to the The material opening 3, the other end is connected to the material outlet 4, the rotating cylinder is horizontally inclined downward at a certain angle along the direction from the material inlet to the material outlet, and a number of copying boards 5 are fixed on the inner peripheral wall of the rotating cylinder. The copying boards are at least two groups distributed along the circumferential direction of the rotating cylinder, the inner copying boards in each group are evenly distributed along the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com