Preparation method and spinning of high-concentration recombinant spider silk protein spinning solution

A technology of spidroin and solution, which is applied in the field of artificial spider silk preparation, which can solve the problems of long-term, unsuitable high-molecular-weight recombined spidroin, environmental pollution, etc., and achieves improved toughness, difficulty in aggregating into disordered precipitates, and stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

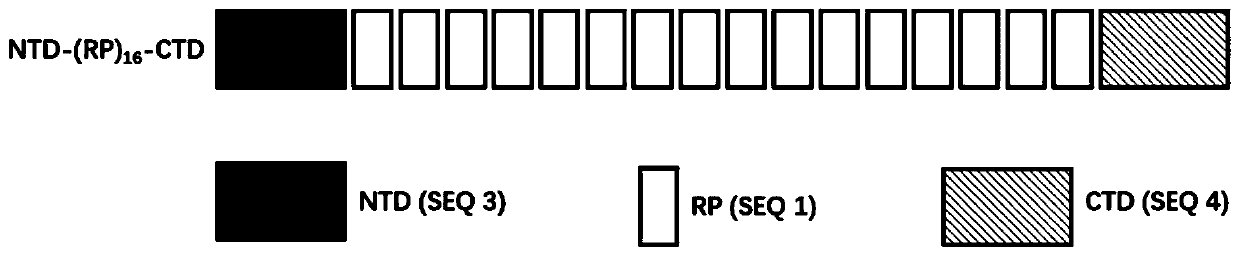

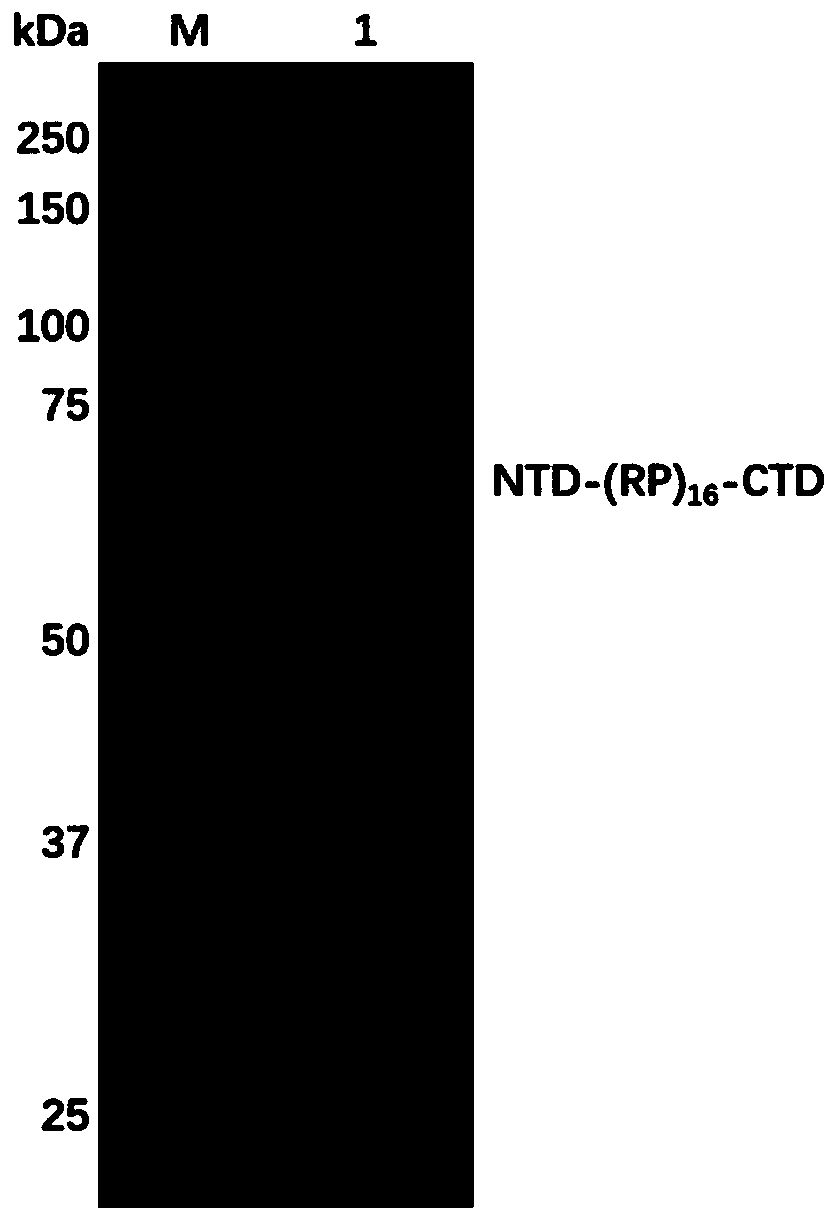

[0037] Such as figure 1 As shown, the recombinant spidroin protein used to prepare artificial spider silk involved in this embodiment is NTD-(PR) 16 -Molecular architecture of the CTD.

[0038] This embodiment relates to the preparation method of the above-mentioned recombinant spidroin solution, comprising the following steps:

[0039] Step 1) Escherichia coli cells expressing recombinant spidroin protein were resuspended in a wall-breaking buffer solution containing 2 mol thiourea and 8 mol urea at a mass ratio of 1:10, stirred for 12 hours, and then centrifuged to collect the supernatant to obtain the recombinant Spider silk protein mixture A;

[0040] Step 2) Adjust the pH of the mixed solution A obtained in step 1 to 4.0 to precipitate some impurities, and collect the supernatant by centrifugation to obtain the recombinant spidroin protein mixed solution B;

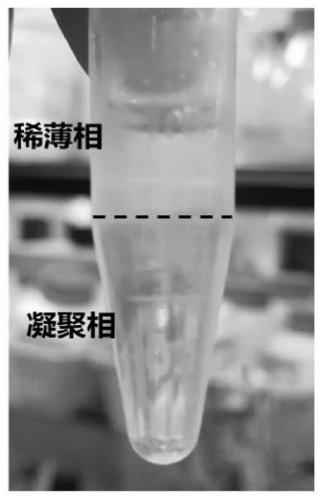

[0041] Step 3) Dialyzing the mixed solution B into a buffer solution containing 0.3 mol of sodium chloride to o...

Embodiment 2

[0052] This example relates to high component NTD-(PR) 64 -The preparation method of CTD recombinant spidroin protein solution, comprises the following steps:

[0053] Step 1) Escherichia coli cells expressing recombinant spidroin protein were resuspended in a wall-breaking buffer solution containing 2 mol thiourea and 8 mol urea at a mass ratio of 1:10, stirred for 12 hours, and then centrifuged to collect the supernatant to obtain the recombinant Spider silk protein mixture A;

[0054] Step 2) Adjust the pH of the mixed solution A obtained in step 1 to 4.0 to precipitate some impurities, and collect the supernatant by centrifugation to obtain the recombinant spidroin protein mixed solution B;

[0055] Step 3) Dialyzing the mixed solution B into a buffer solution containing 0.3 mol of sodium chloride to obtain the reconstituted spidroin protein mixed solution C;

[0056] Step 4) Heating the mixed solution C in a water bath at 80° C. for 20 minutes to precipitate some impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com